The Effect of Brass on 223 Accuracy

Another Variable

feature By: Charles E. Petty | April, 13

The first of those (Handloader No. 248) looked at primers where everything else was constant. That revealed the rifle had a distinct preference for Remington Benchrest primers. Next was seating depth, and again I found the sweet spot with bullets seated 0.030 inch off the rifling.

All that testing had been done with new Winchester brass, largely because I had plenty, but if you really want to open a can of worms, all you have to do is gather two or more shooters and start a conversation about brass and what to do to it.

Let me state up front that I got involved in this game because I like to shoot. If I wanted to take one poor little piece of brass and nurse it to perfection, and then turn around and do all the same stuff to another one, I’m pretty sure I would have taken up a new sport decades ago. But we are told that in order to get good results from our reloads, we must go through endless stages of preparation first. I just read a piece in one of the major gun magazines that explained what we had to do: clean primer pockets, uniform primer pockets, weigh cases, use brass from the same lot, deburr flash holes and so on. The only problem I had with the article was that nowhere in it were we told why we should do all those chores.

The idea of “uniforming” primer pockets sounds quite reasonable at first. After all, we want to be sure we have reliable ignition. One scholar told me that the time it took for the primer detonation to move around the circumference of the primer was a variable. Well, yes, it is, especially if the detonation only moves around the outside, but that isn’t how it works, is it? When the firing pin strike compresses the mix between cup and anvil, the explosion originates more or less in the middle and goes in all directions at a rate of something over 20,000 fps, and I cannot for the life of me see how it would matter. A large primer is 0.210 inch in diameter, so half of that is 0.00875 feet. That means it would take the flash 0.000000437 second to get there. Really?

Well, what if one leg of the primer anvil did not touch the bottom of the primer pocket? The answer is the same. The primer is still going to pop, and our world will continue to revolve. Sure, in a very worst case we might get a misfire, but for that to happen the primer would have to be so high that even a cursory inspection should reveal the error.

Well, how about deburring flash holes? Once more this has the ring of logic, because we want the primer’s fire to get to the powder as easily as possible. It has been suggested that a burr or uneven flash hole can cause turbulence within the burning powder charge and upset its harmony. I can certainly see how that might happen, but again how do we show cause and effect?

Now let me say this clearly: I cannot prove that all the case preparation we are told to do is worthless, just as I cannot prove its benefit. My efforts with each segment and then with cases that have been given the whole “magilla” compared to unprepped brass have always given the same result. In fact a couple of times, brass with dirty primer pockets actually gave smaller groups than those that were squeaky clean.

So as my journey with the Cooper continues, I want to look at things we can control that might actually give us a trustworthy result. One of those things is the make of brass we use.

By now it is obvious that I have a new challenge: to use my proven load and rifle with brass as the only variable. We’ve talked about all the labor we’re supposed to go through to get brass ready, but wouldn’t it be cool if we could just buy some and know it was going to work?

Some other recent testing showed that variations in neck thickness can influence accuracy, but neck turning is one of those chores best avoided for sporting rifles. Reputable sources tell us that variations no more than 0.0015 inch (one and a half thousandths) are best for good accuracy. Using Redding’s new Neck Thickness Gauge, I was able to sort some new Winchester brass into three groups by neck thickness variation: .0010 inch or less, .0015 and .0020 inch or more. When I shot them using my now-standard load, there was a 20 to 25 percent improvement in accuracy as neck thickness variations were reduced.

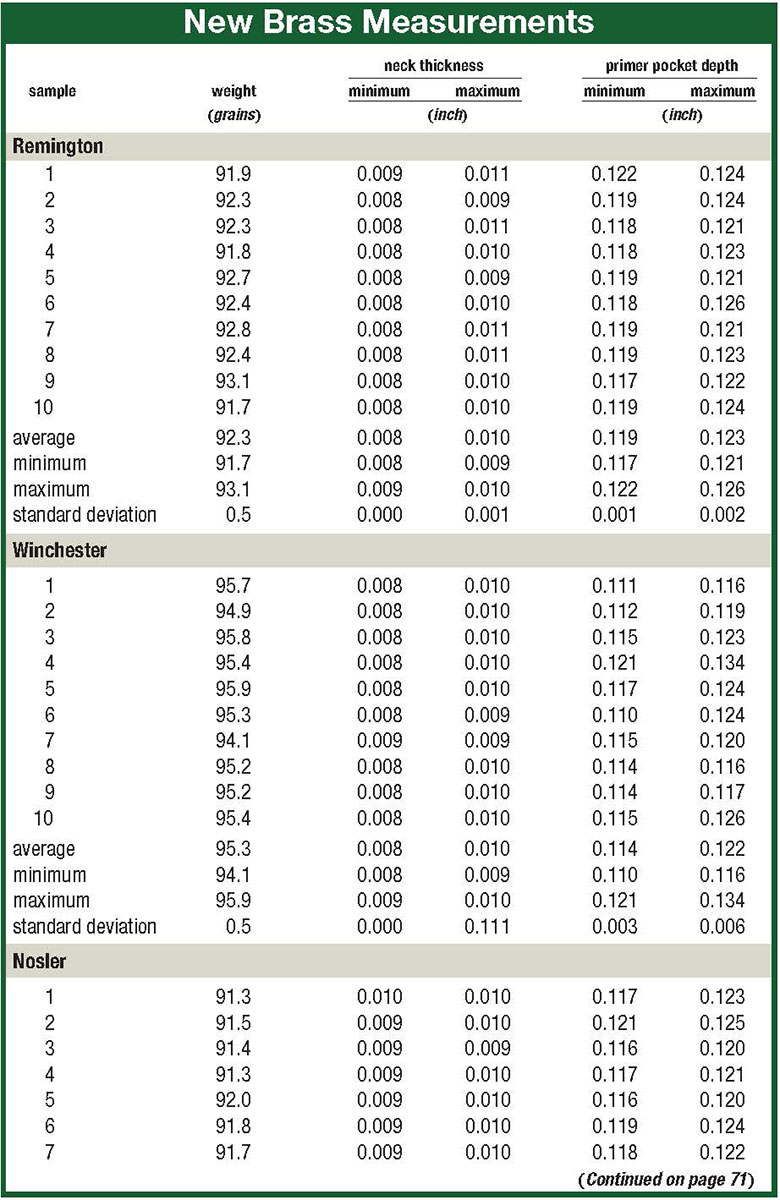

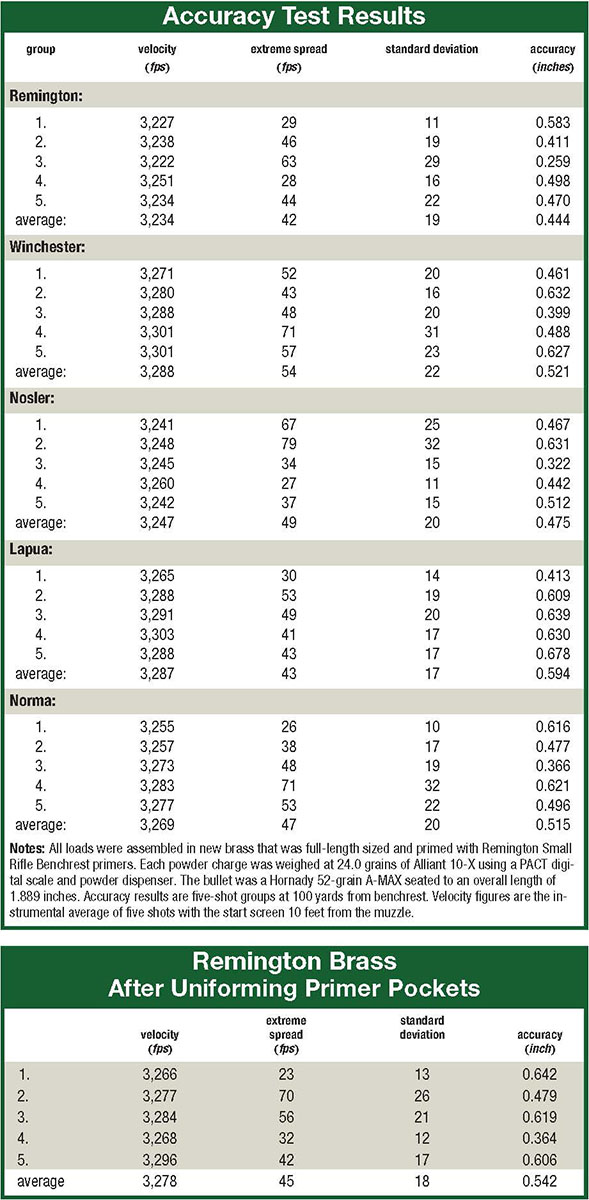

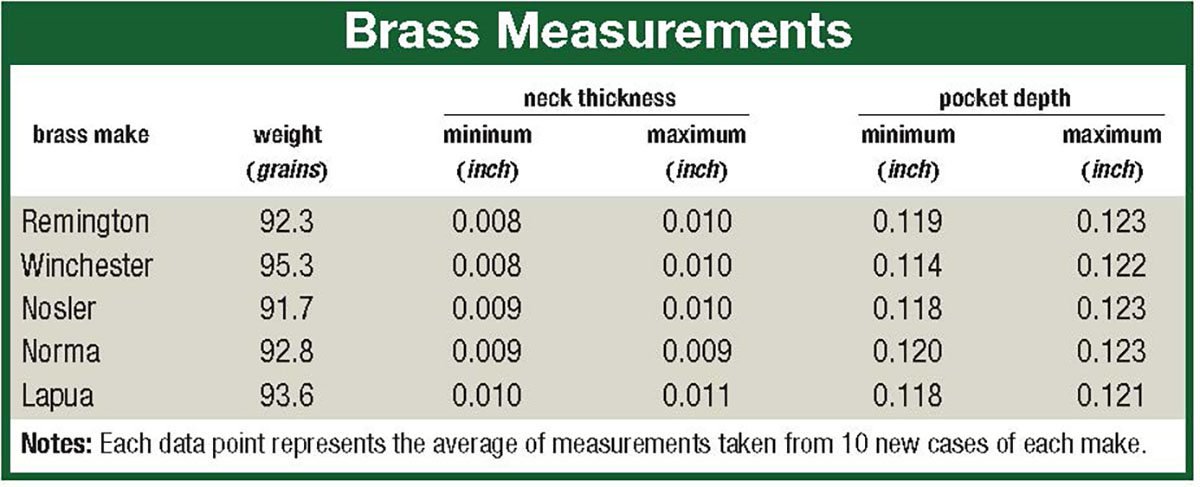

Now we have a group of variables that can be measured between the various makes of brass, and I began the tedious process of weighing and measuring to gather the data shown in the table. As I said before, primer pockets and I have only a passing acquaintance, but it did seem reasonable to see if there was anything relevant there. I don’t know whether there is or not, but there were some differences. In most cases the primer pocket is formed fairly early in the cup-and-draw process of brass manufacture and then pierced during priming of ammunition or as a final brass manufacturing step. In most cases the piercing operation will leave the pocket slightly concave, so using a digital depth caliper, I measured the depth right at the side of the pocket at four equidistant points around the circumference and reported the minimum and maximum depth. Quite obviously the next step of this odyssey will have to be looking at “uniforming” some of those to see if it matters.

No matter how hard we try, it is difficult to embark on a project like this without some expectation of how the results will turn out. We have been told time and again that premium brass is better, and it certainly seems that it is more consistent – although it would be a stretch to call any of it bad.

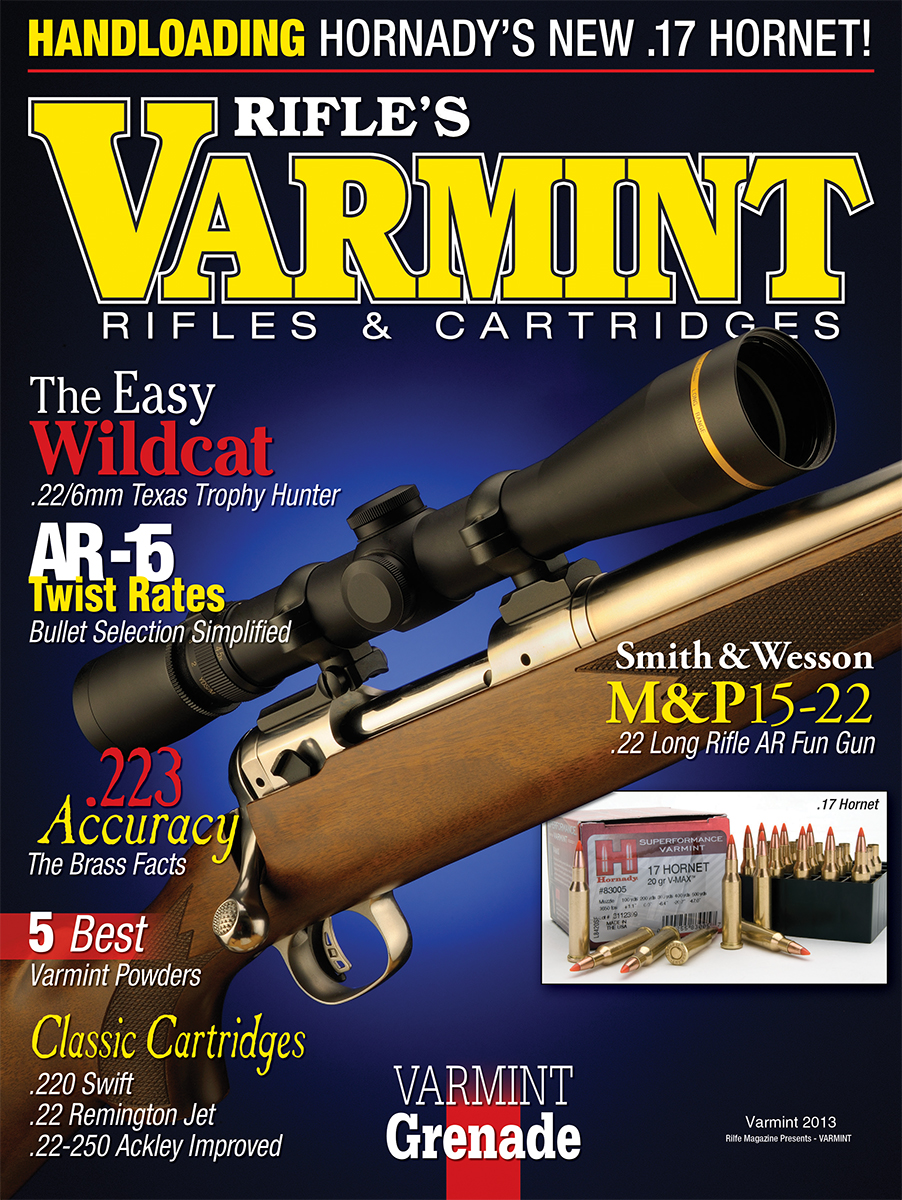

All the ammunition was loaded with care, charges were weighed, and I did all I could to get it right. Twenty-five rounds of each make of brass were loaded so we would have five groups of five shots. The shooting took place in mid-October with temperatures in the low 70s. Winds were very light, and I took care to watch for changing conditions. The shooting scheme was to start with a cold, clean rifle and fire two fouling shots and then the five groups at a measured pace to avoid overheating. The barrel never got so hot that I couldn’t hold it.

As I look at this data, I remember saying that one goes into this type of test with an expectation of what the results will be, and this just proves to me what a bad idea that is. Conventional wisdom would predict that the most consistent brass would be more accurate, but the real fact is that we can’t say one make of brass is better – or worse – than another. The differences are simply too small to allow that sort of judgment. Of course, I must also insert some weasel words and say your results may be different and this data applies only to my rifle on that specific day with the moon in Aquarius.

Statistical analysis of the data using the student’s “T” test reveals no significant difference in accuracy among the various makes of brass at the 95 percent confidence limit normally used for this type of evaluation. If we reduce that to 90 percent, then the Remington brass has an advantage.

The data also shows that there is no way we can use standard deviation to predict accuracy. Within each series of five-shot groups, we have standard deviations that vary by several orders of magnitude, and some of the smallest groups have a higher SD.

Please remember that these were all weighed charges where the scale read 24.0 grains with no tolerance on my part beyond whatever is built into the scale. Yet there is a pretty sizable velocity spread within some groups. This is probably the best highlight I can find to show that no matter how hard we try to be precise the very system has so many built-in variables that sometimes it feels positively Quixotic to sweat the small stuff. Instead we should thank our lucky stars that yon distant barn has a hole in it.