.219 Zipper

Factory Standard of a Bygone Era

feature By: Stan Trzoniec | August, 11

Working with the .219 Zipper was an itch that just had to be scratched, and looking around local gun shows the last few years for a rifle suitable for my use that was already chambered for the Zipper proved futile. I did come upon a Marlin chambered for this little .22-caliber screamer, but looking closer, the innards were a complete mess. It was obviously left in a barn to its own devices, and since there was no ammunition to be found, the owner had given up using it around the farm.

Although the dealer thought he had a real collector’s item (so he told me), I let it pass. I never did come across a Winchester Model 64 chambered for the Zipper, and if I did I probably would have walked away from the deal simply because I really wanted something newer and more up to the task when it came to accuracy. As a last resort, I was going to purchase a Ruger No. 1 but then again had a difficult time finding someone with reamers to convert this single shot to my dream cartridge.

Turning to Thompson/Center, its custom shop could do a barrel in the Zipper and that was all I would need to get the project started. Since I already had a rifle (receiver) and used it in other Handloader projects, all I had to do was mate the new 24-inch barrel with my test bed receiver and thumbhole stock. Adding a Leupold double dovetail base, medium rings and a Bausch & Lomb Elite 3-9x 40mm scope put me into the shooting business. Now all I needed was the cartridge to go with it.

The .219 Zipper was introduced by Winchester around 1937. Based on the .25-35 WCF rimmed case, at the time, chambering it in a levergun seemed like a good idea considering a lot of America was still in the farming stage – and who in their right mind would not have a .22-caliber levergun on the farm. While you would think it might have appealed to dyed-in-the-wool varmint hunters, after the initial reports came out on mediocre accuracy in the levergun, most all these hunters went right back to their custom-made, bolt-action rifles. I do not recall reading of factory bolt-action rifles being chambered for this particular cartridge, but it would be a natural considering its tapered case with a 12-degree shoulder angle and lower than normal (40,000) breech pressures.

At the time, the Zipper seemed to be a milestone in varmint cartridges simply because of its range and flat-shooting characteristics. Chronographing the 46-grain bullets back then revealed they could achieve around 3,390 fps; the heavier 56-grain bullets reaching around 3,050 fps. The Model 64 (aka deer rifle) .219 Zipper was kind of a special deal, as it came out of the factory with a 26-inch barrel and a receiver peep sight.

Maybe this is where the Model 64 .219 Zipper gave a false impression to its owners. After all, any cartridge chambered in a so-called “deer” rifle should be good enough for hunting deer. Wrong. For small game at closer ranges, the .219 Zipper was at peace with itself if one limited the rifle (those with open sights) and cartridge to less significant game at 100 yards or so. With a good scope, you could boost that to around 150 yards if conditions were in your favor. For medium game at moderate distances, the Zipper might outdistance the .22 Hornet, but I’d opt for something a little bit stronger in bullet weight and velocity. At that time, you were looking at something like the .22 Hi-Power.

Looking through a pile of research material, most of the writers of that period found the Zipper lacking in accuracy – most of the problems being ver-tical stringing – with factory loads delivering groups anywhere from 4.5- to more than 8.5-inch vertical spreads. On the other hand, when handloads were employed, groups started to shrink to the point where they were tolerable at moderate var-mint distances.

After reviewing all the data available, I decided to go ahead with loading the .219 Zipper, but like others in its obsolete class, brass was the problem. In short, there is not any around, so back to the drawing board to see what I could make work with my fresh Contender barrel. Winchester still makes .25-35 brass and sells it as a component, and you can use that; but since I had plenty of .30-30 Winchester cases, I decided to go with that, which I did with the .219 Donaldson Wasp sometime back. However, be forewarned that working with the Zipper requires patience and concentration. Aside from the Contender barrel, dies are the next expenditure.

For dies, I again turned to my friends at Redding (1089 Starr Road, Cortland NY 13045) and ordered the following items, which can also be purchased from your local dealer. These will take you through the complete case forming and loading cycle of the .219 Zipper.

#90360 Custom Form #1 Die

#94360 Custom Form #2 Die

#83360 Form and Trim Die (Series C)

#80360 Full Die Set (Series C)

Aside from this, round up at least 100 factory fresh .30-30 Winchester cases. With wildcats, I always start with this amount or more if the forming process is going to be intense, that way once one particular die is set, I can move along smartly from one step to the next. The only drawback, of course, is that if you make a mistake along the way, you have to start over. To eliminate this, I am careful with each step, checking and double checking dimensions after the first five or six cases clear the forming die thus offering an “average” of what is going on within the die.

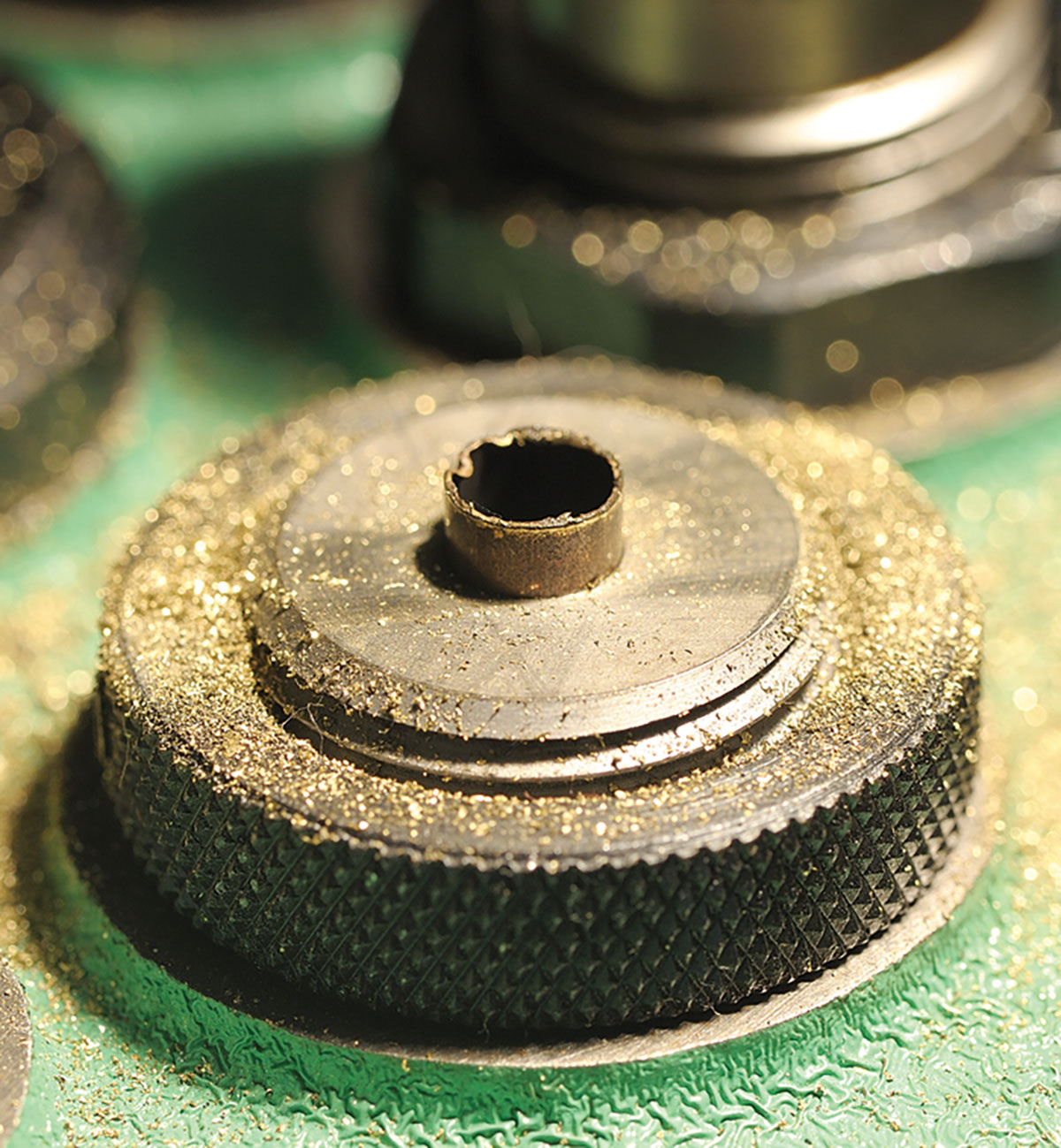

The only real problem I had working with the .219 Zipper was the same I had with the .219 Donaldson Wasp and revolved around the #1 form die. Because the shoulder had to be pushed so far back, shoulder (or case) dents were a major problem. Annealing did help somewhat but not completely. I tried the Redding Imperial sizing wax, which did help, but again not entirely. A much better solution was to place a little case lube on the very top of the case mouth before running it into the die. In this way, most of the lube was expended on the neck before it reached the shoulder, preventing much of the denting due to buildup of lube inside the tight tolerances of the die. You might never get rid of all the dents, but they can be blown out later with a “forming” charge that, in addition, helps to fireform the case precisely to the Contender chamber.

For bench equipment, I use the Redding T-7 press. Since it is a turret press, once set up with the dies, I can move along at a comfortable pace. With seven openings all the forming dies and the regular full-sizing set can be mounted without the hassle of resetting a die throughout the entire process, especially if there is trouble with headspacing or chambering. It has the much needed leverage so desirable with forming even the most formidable wildcat cartridge.

Getting started, install the #1 form die so when you run the ram up it just contacts the #2 shellholder. Pushing the shoulder back from 1.441 inches (.30-30 parent case) to 1.359 inches (.219 Zipper case) is roughly 0.082 inch and requires some physical effort. Also, the inside neck diameter is reduced from .330 inch (.30-30) to .285 inch on the first pass.

Using the next or #2 form die is somewhat easier only because the neck is reduced to .260 inch. Hint: Do not wipe any of the lube off the case, as whatever is left from running it through the #1 die is more than enough to get you through the rest of the operations.

The trim die is next and is nothing more than installing the die in the press and cutting off the excess neck length. In all probability, this is the most labor-intensive part, trimming it to length with a handsaw. When the case pops out of the trim die, it has an overall length of around 1.952 inches. Follow this with a file, finishing in a case trimmer to 1.928 inches. I try each case in the chamber of the Contender barrel before moving on to chamfering, priming and loading with a charge for fireforming. It is also a good time to check the inside dimension of the case neck to see if you have to use a reamer or not. Using Remington brass, I was left with an inside measurement of .222 inch before entering the full-length sizing die.

Before you can prime or load, all cases must be put through the full-length sizing die from the #80360 set, where the neck is brought down from an outside diameter of .255 to .245 inch with an inside diameter of .223 inch – perfect for loading standard .224-inch bullets. Out of the sizing die, you are looking at an over-all length of 1.935 inches, still below the maximum case length of 1.938 inches – and above the minimum of 1.928 inches.

With all the cases individually chambered in the Contender barrel to ensure a good fit, priming was next. Most recommend the use of the Federal 210M Large Rifle, which is its version of the popular benchrest primer and a good way to squeak the last bit of accuracy from the .219 Zipper.

After priming, and to smooth out any case dents, I fireform all cases with a mild load of 24.0 grains of BL-C(2) under a common 50-grain, .224-inch bullet. This gives around 3,000 fps and in addition to forming the cases, allows me to sight in the rifle. You will want to use a fine-grained powder for this kind of duty, as charging goes much faster without the need for trickling.

After fireforming and before neck sizing, the cases grew to 1.940 inches. After carefully setting the full-length die to neck size only,

I ran all the cases through, cleaned them and checked for overall length. Afterward cases were trimmed back to 1.930 inches before making my selections on powder and bullets for the final range testing.

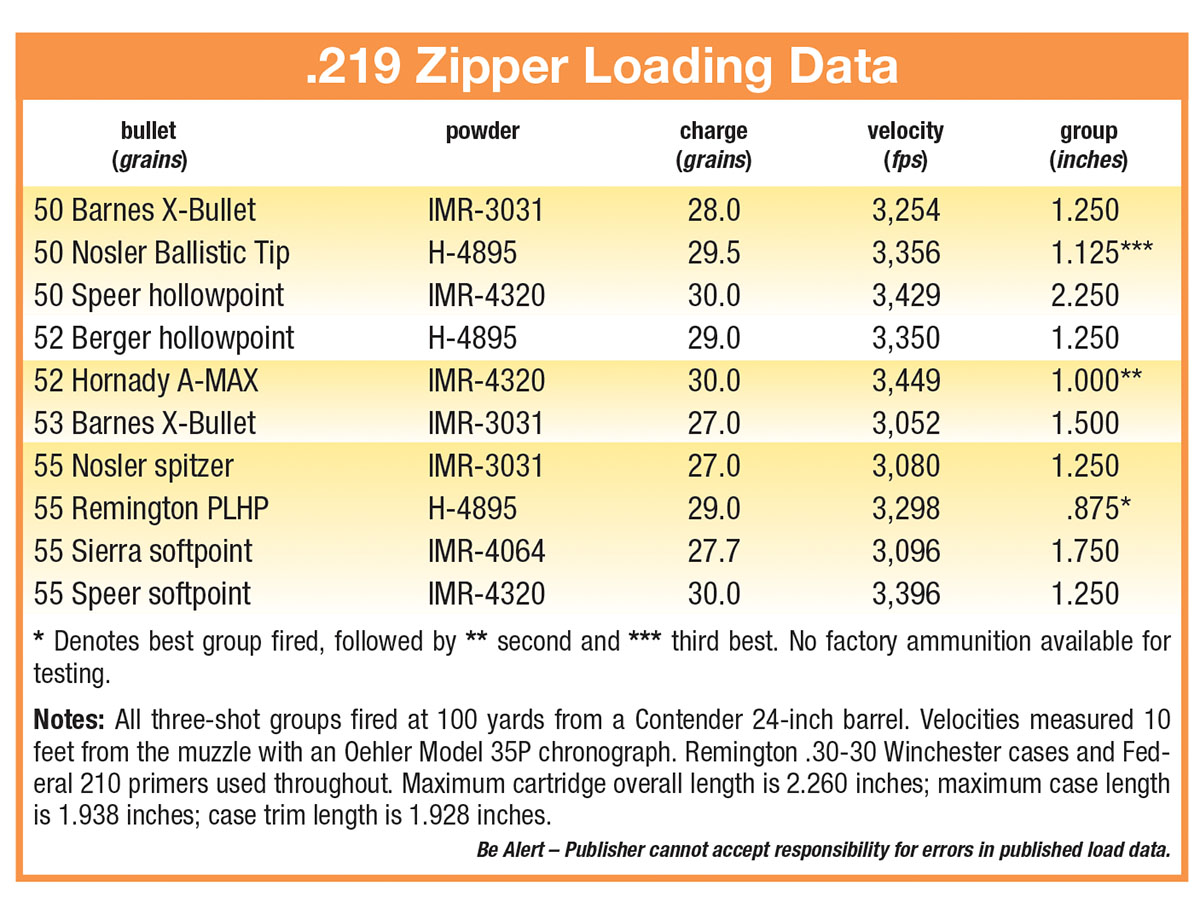

For loading data, Hornady and Sierra (and LoadData.com) had pages of information, but even so I wanted to compare modern specs with some of the old masters who ran the .219 Zipper through its paces right after Winchester introduced it. Checking the likes of Sharpe, Landis, Ness and Stebbins, it is interesting that not much has changed in the way of powders over the past seven decades. For instance, all seemed to concur on the use of IMR-3031, IMR-4064 and IMR-4320 for a variety of bullet weights, while modern writers like Ken Waters gravitated to IMR-4895. In fact, checking modern sources, a load of 27.0 grains of IMR-4064 that F.C. Ness recommends and 26.5 grains from the handloading book of Phil Sharpe (with a 55-grain bullet) is still right in the ballpark of Hornady’s current manual with its listing of 27.7 grains as maximum for a case with a capacity of 33 grains of water.

In comparing apples to apples, or the Sierra to the Hornady manual, the former seemed to be a bit more conservative in its loading data. Since it is hard to visualize who is going to use what powder in what gun, Sierra obviously decided to err on the safe side. Using a 50-grain bullet, Sierra lists 27.9 grains of IMR-4895 as its maximum load (3,500 fps) with a slight step down to 26.7 as its “accuracy load” for a velocity of 3,400 fps, using of all things a Winchester Model 54 with a factory 24-inch barrel. Looking at the Hornady book and using H-4895 (for all intents and purposes the same burning rate), it lists 30.2 grains for a book velocity of 3,600 fps in a 27-inch barrel. Naturally, it’s your call, but in a modern Contender barrel, you could go for broke, split the difference if you are playing accuracy over velocity, or throttle down a bit for more accuracy. Since I am starting out with .219 Zipper loads, I begin with the loads somewhat below maximum, which offers the best of both worlds – a more than decent velocity downrange and good accuracy to boot.

Bullet weights in 50, 52, 53 and 55 grains are my preference for small field game such as woodchucks and such. For smaller game, I’d opt for 45-grain bullets; anything larger go for the 60-grain offerings or switch to another cartridge. Since the Hornady book recommends H-4895 over all bullet weights, I have included it here, as well as time-proven IMR-3031, IMR-4320 and IMR-4064.

When it comes to bullets, again, everyone has his preference for small or large game, and over the years I have come to trust various products from Barnes, Berger, Hornady, Nosler, Remington, Sierra and Speer. Accuracy, of course, is paramount for var-mints; velocity comes next with the type of bullet or design for the type of game being hunted. In New England where ranges go from 100 yards between stone walls to the maximum I’ve shot across a newly cut field (325 paces), these products worked on woodchucks, annoying crows (if they don’t spot you first) and a gray fox raiding the chicken coop.

Loading went on without a hitch. After running all the fired cases through the full-length die, I checked for overall length, primed all cases and then went through the process of picking out loads. I used the Hornady manual for the final loads using the appropriate bullet weights with the powders and bullets to obtain a good picture of what the Zipper is capable of. Aside from H-4895, IMR-3031, IMR-4320 and IMR-4064 needed to be trickled on the scale to bring all charge weights up to the correct number shown in the table.

Out on the range, I had groups that went from super accurate to ho-hum results at 100 yards. All the groups shown are three shots, which I consider fine for varmint work, and tallying the results was certainly interesting. Temperature at the time was around 65 degrees Fahrenheit with a very light breeze coming in from the south.

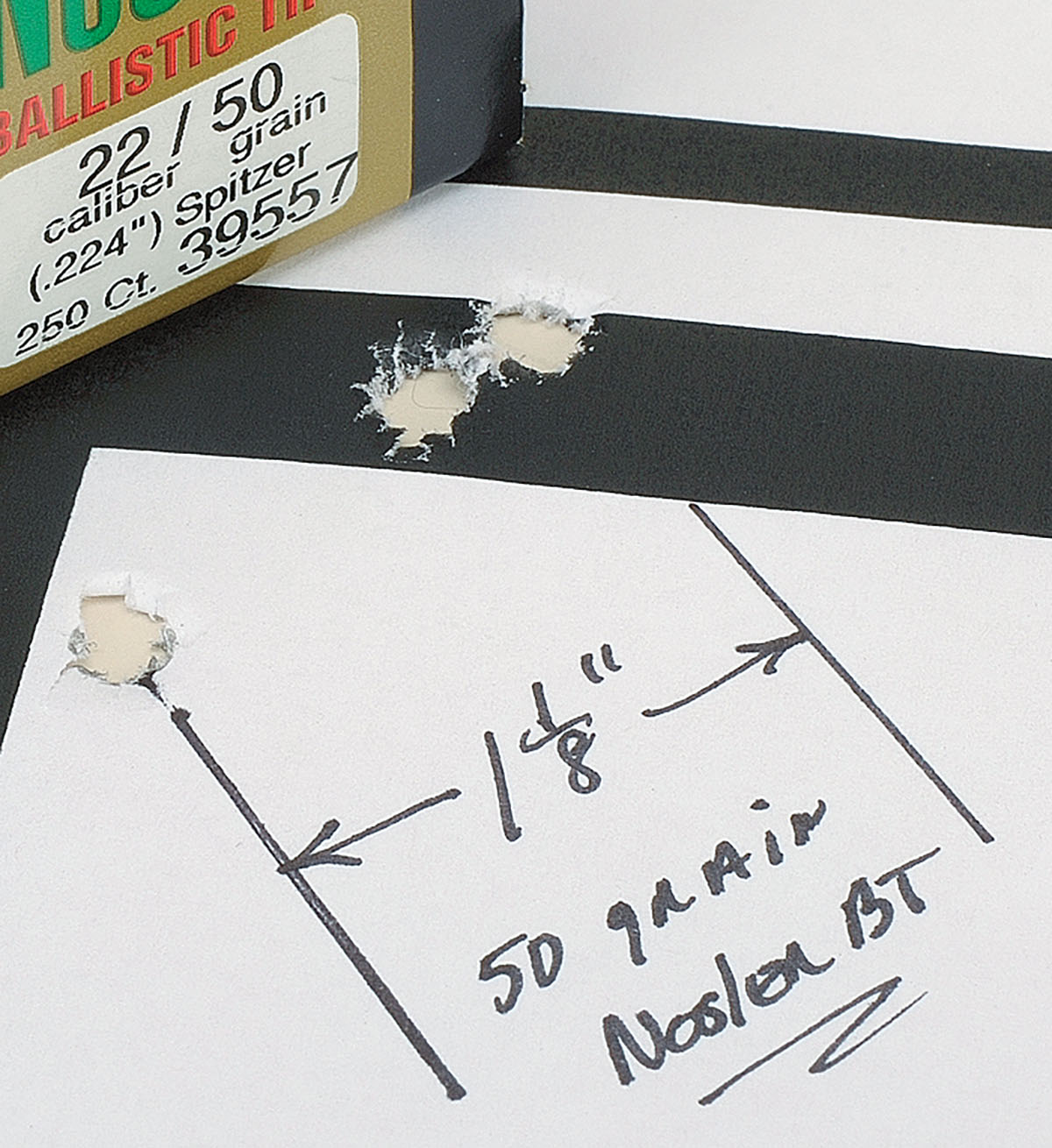

Starting with the lighter, 50-grain bullets, the Barnes bullet with IMR-3031 had the lowest velocity of the group. Nosler’s Ballistic Tip with H-4895 came in next with 3,356 fps, and this one held promise as two of the three shots were touching. Finally, using IMR-4320 proved futile with Speer hollowpoints, as though velocity was up a notch but accuracy was not.

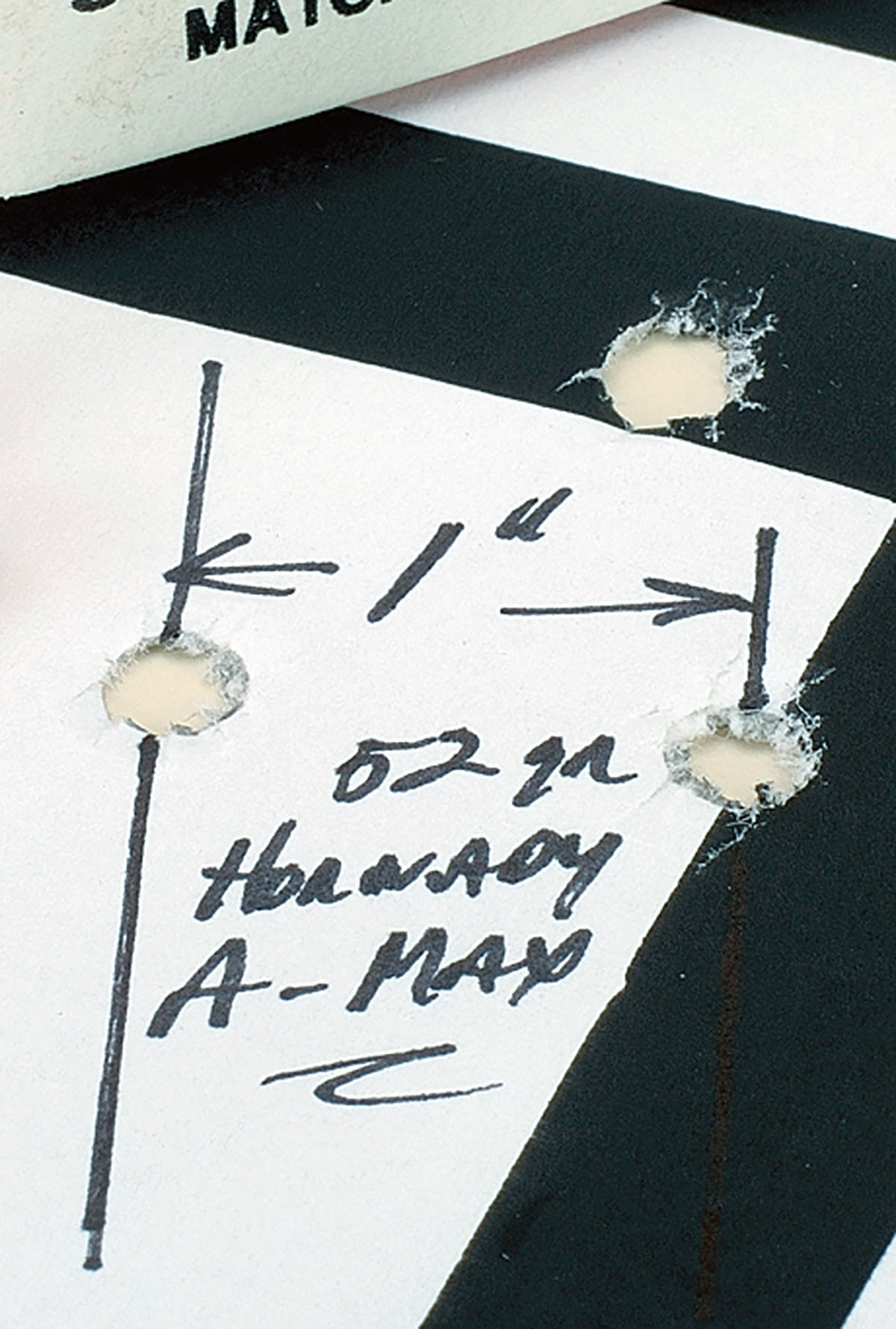

I started to see real promise as I approached the heavier bullet weights. While the Barnes and Berger bullets hit average group sizes, the Hornady A-MAX Match with 30.0 grains of IMR-4320 did well with both high velocity and neat one-inch groups.

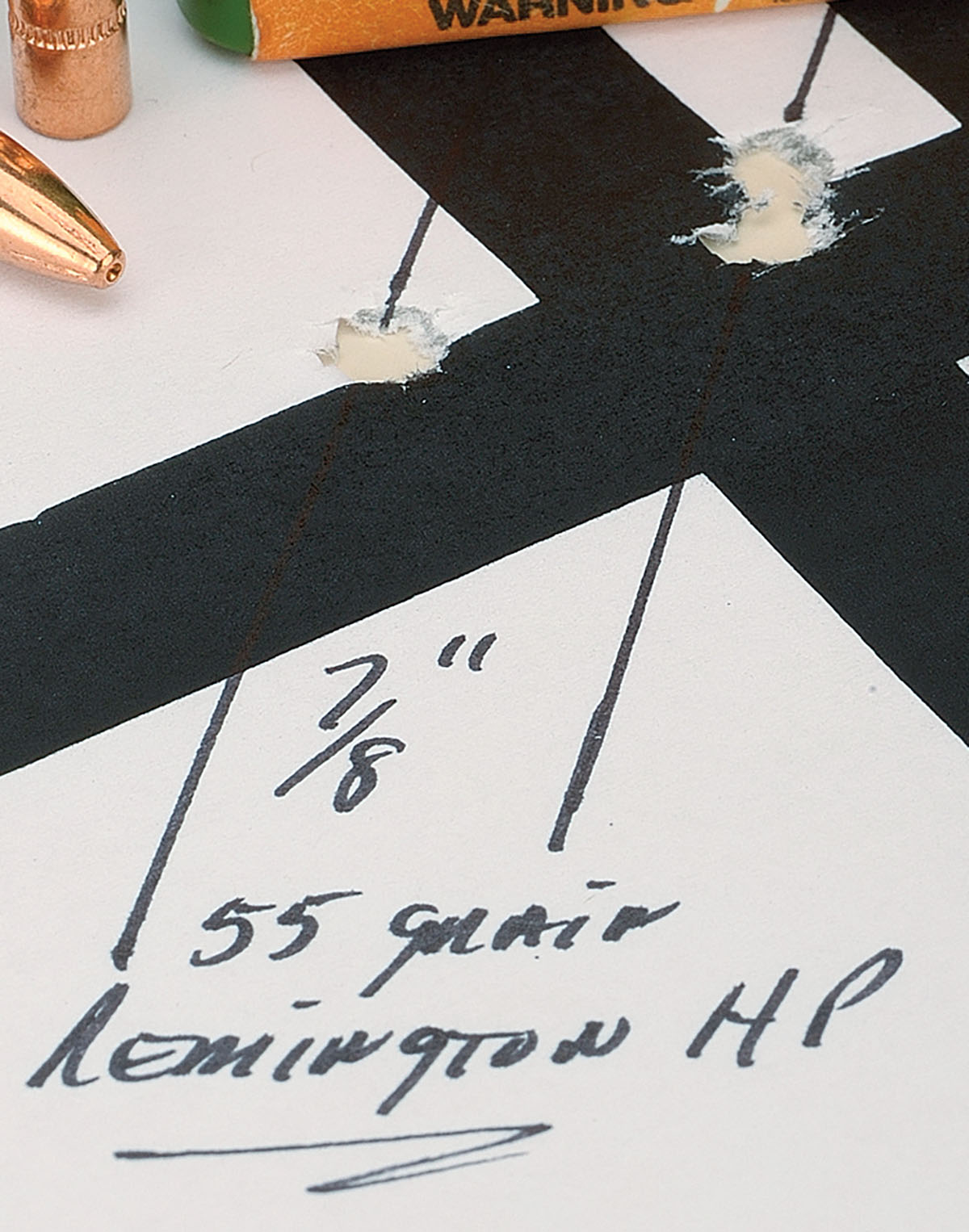

I hit pay dirt with the 55-grain bullet offerings. I like this bullet weight for larger varmints, as it seems to offer a good balance in the .22-caliber range, especially if you team the right bullet with the right powder. Both the Nosler spitzer and Speer softpoint hit over an inch, while the Sierra softpoint went almost 2 inches. However, the group that got the prize of the session was Remington’s 55-grain Power Lokt hollowpoint that I’ve found over the years has yielded the most consistent results regardless of the .22 centerfire I have used it in.

As an interesting footnote, I believe it was slightly over 20 years ago that I found this bullet and, concerned it would be discontinued, purchased 20 boxes. Much to my chagrin, Remington, knowing when it had something good, still offers this bullet under its stock number RB224P2. With an applied cannelure and a concave base, I know match shooters who swear by this bullet. Loaded with 29.0 grains of H-4895, it yielded groups under an inch, a load that was verified three more times, which now makes it a strong contender this spring for hunting/shooting chucks.

Reviewing, we see that H-4895 is the accuracy champ, followed by IMR-3031 and IMR-4320. If you’d rather have velocity, I would go with IMR-4320, H-4895, then IMR-3031 and scratch IMR-4064 on both counts. Striking an average, H-4895 is my top choice for a propellant in the .219 Zipper.

Looking closely at comparisons, we note the .219 Donaldson Wasp and the .219 Zipper are so close in velocities (by the book now) that if you had one, would you really need the other? For example and placing both side by side, the Hornady book shows that with a 55-grain bullet in the .219 Donaldson Wasp, you need 28.3 grains of H-4895 to reach around 3,400 fps. With the Zipper, 28.6 grains will get you 3,400 fps, while a pinch more (29.5 grains) will net 3,500 fps.

Shortchanged by its availability in lever-action guns, the Zipper never amassed a large following, which makes you wonder why Winchester put this new cartridge in that type of firearm from the get-go. In all honesty, I believe Winchester considered the Donaldson Wasp a competitor if Remington got into commercializing it, and by modifying the shoulder on the Zipper (again making it easier to feed in a levergun) and touting it as a “new” offering, it hoped to capture the spirit of this gun and cartridge combination. While the Donaldson Wasp never did make it big – seems the .22 Varminter (aka .22-250 Remington) was the winner on all counts – neither did the Zipper.

In the end, if you held my feet to the fire, I found the Donaldson Wasp more interesting, especially chambered in a Ruger No. 1 single-shot rifle. On the other hand, the Zipper takes the same amount of manual labor in the forming department, and thanks to Thompson/Center’s Custom Shop, we can have the best of both worlds at a price that is acceptable for most everyone. I enjoy both.