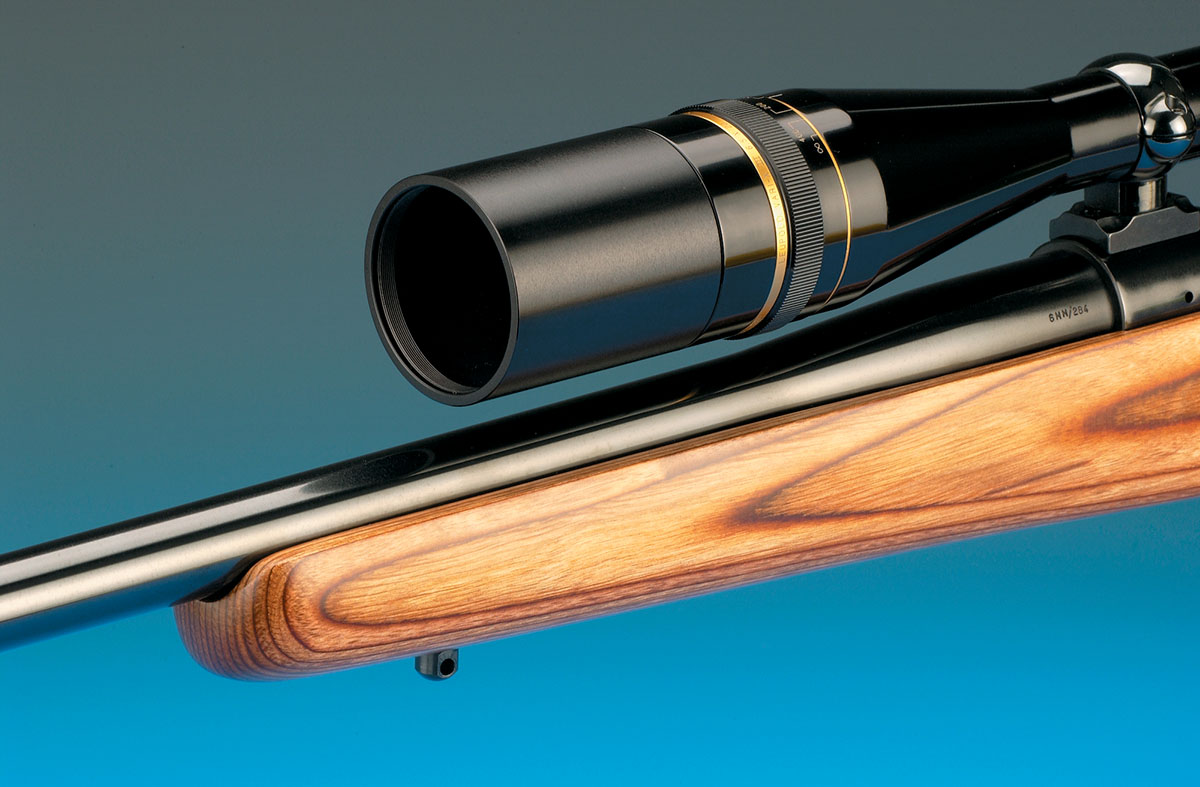

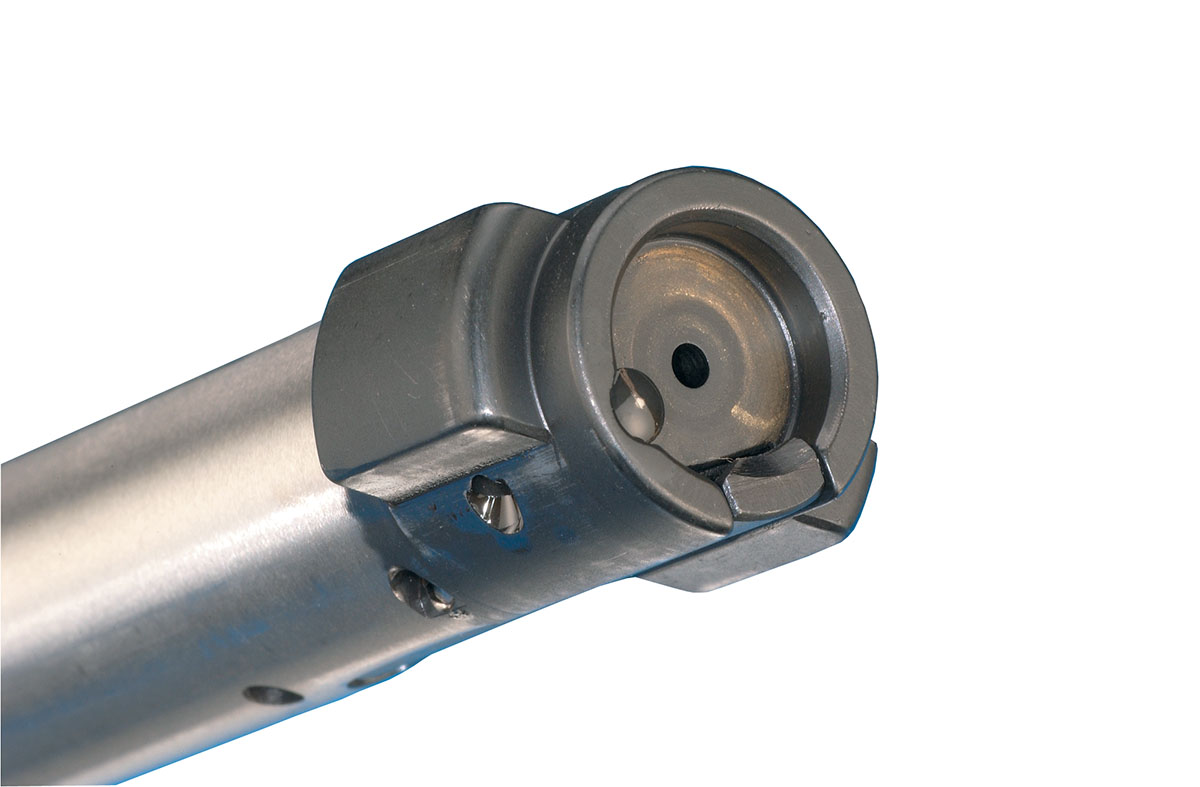

This action features a one-piece forged bolt body that contains a cocking indicator, fluted-style bolt handle and a two-position safety.

Did you ever really want to try something new but upon looking closer found it was so similar to a member of its own ilk that maybe it wasn’t worth the effort after all? That was the question I had to confront when a strange turn of events got me interested in the 6mm-284.

The Howa action has the safety positioned just behind the bolt handle.

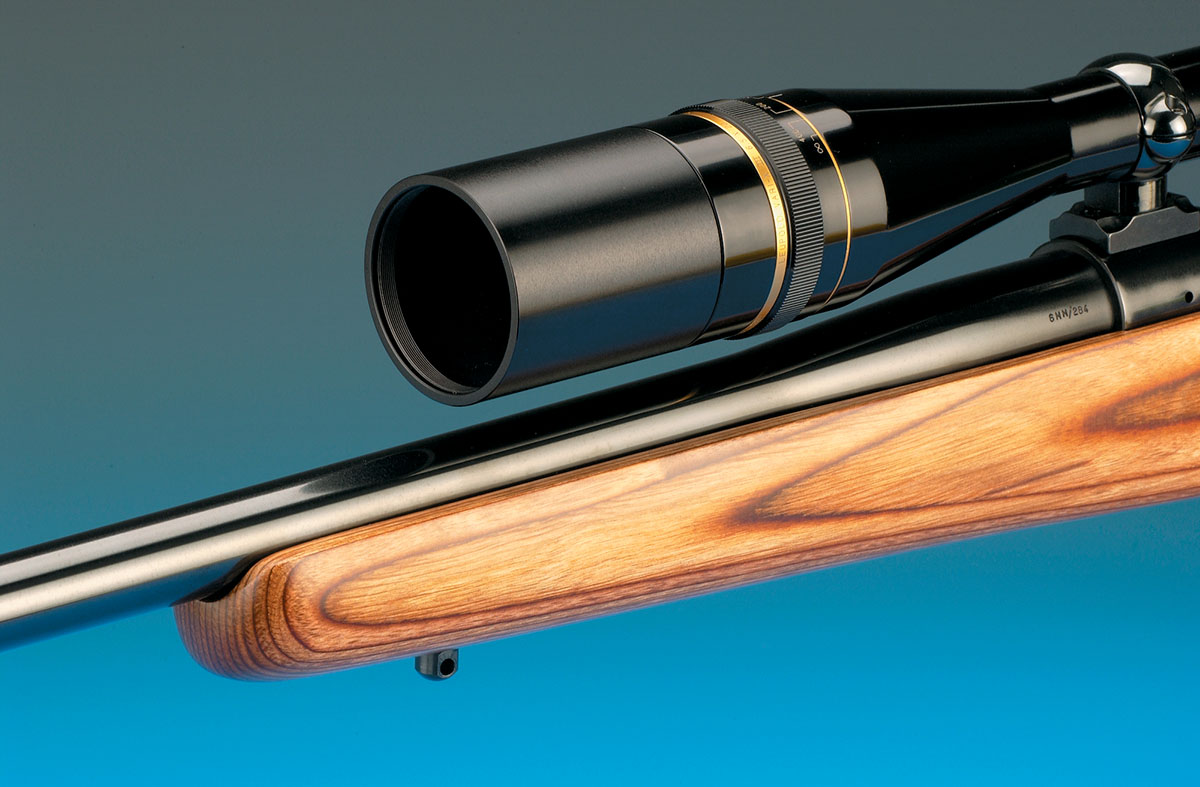

At the outset I wanted a rifle chambered in the

6.5-284 Norma, but since there are no production

rifles commercially available, I set out to have one made. The starting point was a Howa action and barrel that were obtained through normal channels. Since the barrel was going to be discarded, all I had to do was make sure the bolt face matched the .284

Winchester head diameter of .473 inch. Since the .243

Winchester is a perfect match, a barreled action was sent to E.R. Shaw (Small Arms Mfg. Co., 5312 Thoms Run Road, Bridgeville PA 15017) for a new barrel with an order not to change the original outside dimensions or contour.

Inletting on this rifle is perfect, allowing the action to drop into the stock.

While that was away, I ordered a Ross thumbhole laminated stock from Boyds’ (25376 403rd Avenue, Mitchell SD 57301), inletted and completely finished for the Howa action. Since Shaw would match the factory contour of the barrel, I felt pretty confident everything would fall into place when the time came to combine the action with the stock.

That’s one way of doing it, but you can do it in reverse. If you are looking for a “one-step” process, you can order the complete package from Legacy Sports, sans the new barrel, of course. Legacy simply calls it the Howa M-1500 Thumbhole Sporter, and it comes with either a pepper (black/gray) or nutmeg (shades of brown) stock. You’ll want to order a short action in either the .22-250 Remington or .243 Winchester. Take it home and ship the action to Shaw.

There is plenty of room within the thumbhole for shooters with large hands or in the winter when wearing gloves.

Whatever method you use, when the final package is assembled, it makes for one handsome rifle. I picked the blue carbon steel action and nutmeg laminated stock, and everything fit perfectly when the barreled action was returned from Shaw.

The cheekpiece is full and very comfortable to shoot with.

The Howa action has been refined and is very smooth in operation. You might recall this action has been around for quite sometime, having seen service at Smith & Wesson, Interarms and Weatherby. While the first two industry leaders have been in and out of the rifle business, Weatherby still employs the use of the Howa product under the Vanguard moniker and with the beginning of this model year is offering a “custom” Vanguard complete with all the trimmings and a Desert Camo stock. Howa seems to be pulling ahead as far as the list of models and calibers is concerned, so placing an order with a dealer would seem to present few, if any, problems when it comes to availability of either (or any) caliber.

The Boyds’ stock lacks checkering or a forend tip right from the factory. Either feature could be added later.

Basically this action features a one-piece forged bolt body that contains a cocking indicator, fluted-style bolt handle and a two-position safety. The trigger is adjustable, and I tweaked it to break at 3 pounds even. The action is drilled and tapped for commercial scope bases, and you’ll want to order any two-piece base set that is made for the Remington Model 700. If you opt for a one-piece base, you will need this in a short-action model.

The stock arrived from Boyds’, and the action followed within a week. When I looked at the packing slip and the stamping on the barrel, the caliber was wrong! Instead of chambering for the 6.5-284 Norma, somewhere along the line, it was chambered for the 6mm-284. Granted it was no big thing, and Mr. Shaw advised me to return it posthaste for a redo. Apparently (my reasoning now) since the order was placed during the busy hunting season, I can see why this oversight occurred.

Is the 6mm-284 Really Worth It?

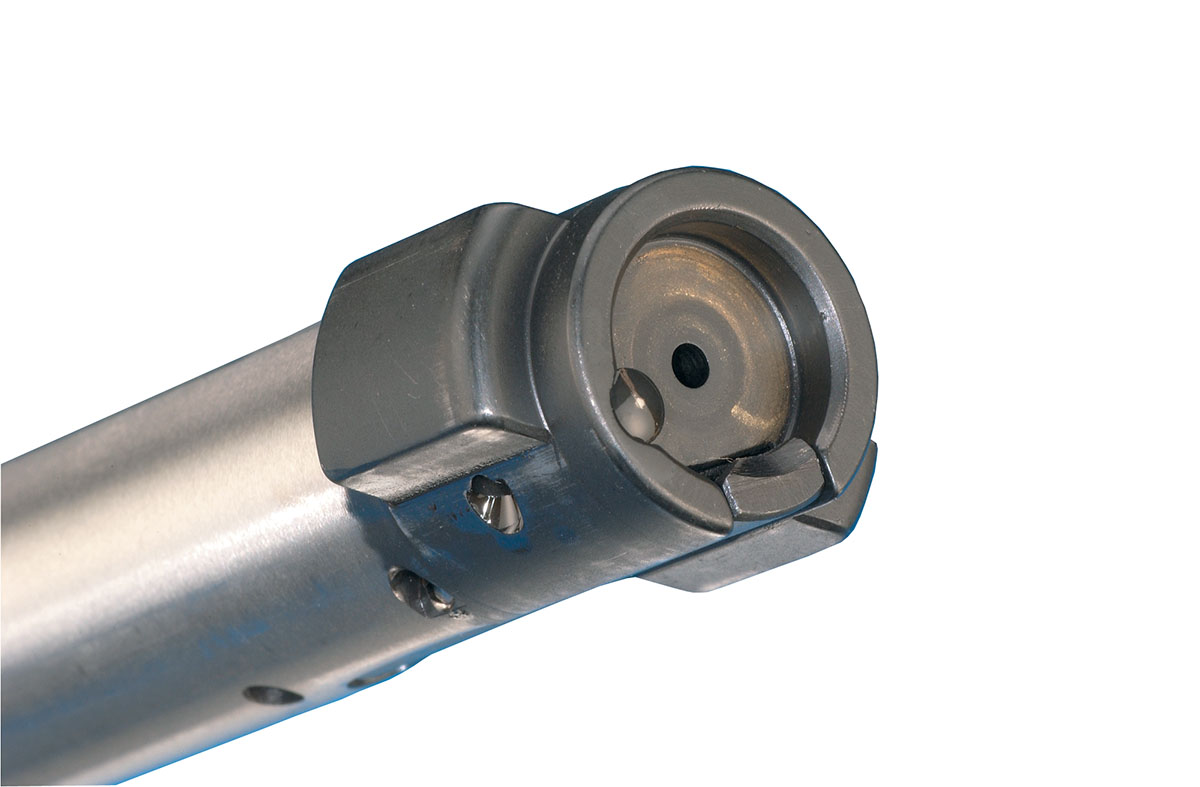

The Howa does not have an external extractor. The plunger-type ejector and extractor are located within the bolt face.

I thought about sending it back, but then again, playing the devil’s advocate and while I still had the rifle in my hands, was the 6mm-284 worth a try? After all, we are still talking about a wildcat, and with a bullet diameter of .243 inch, it would offer much in the way of current bullet designs and more in the future.

Scurrying upstairs to my office, I grabbed for the stats on the 6mm-284 and the 6.5-284 Norma. In the 5th edition of the Hornady Handbook of Cartridge Reloading, notice was quickly given to the fact the 6mm-284 was more adaptable to a wider range of the types of game I’m interested in. I could use the 6mm-284 for varmints with lighter 58-grain bullets, and for pronghorn or other plains game, the 100- or 105-grain bullet would be fine. The 6.5-284 Norma, on the other hand, starts (around 100 grains) where the 6mm-284 leaves off and extends upward to 160-grain bullets.

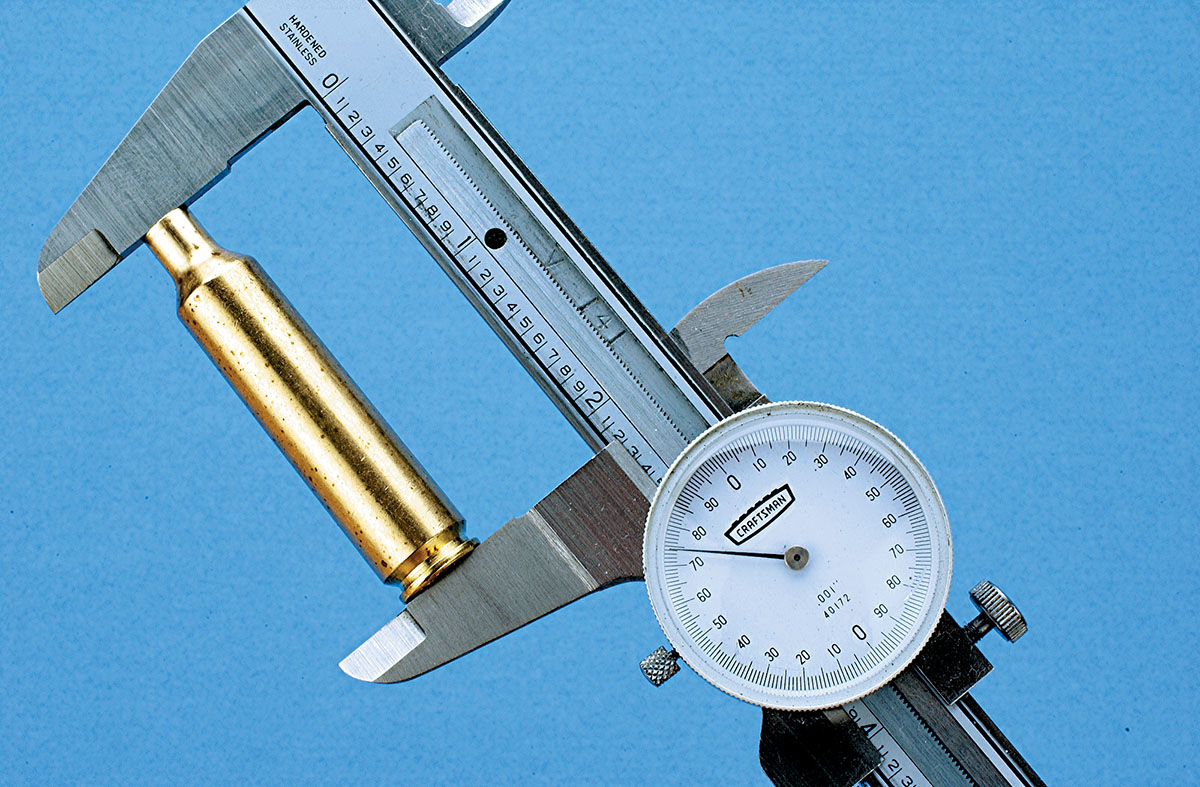

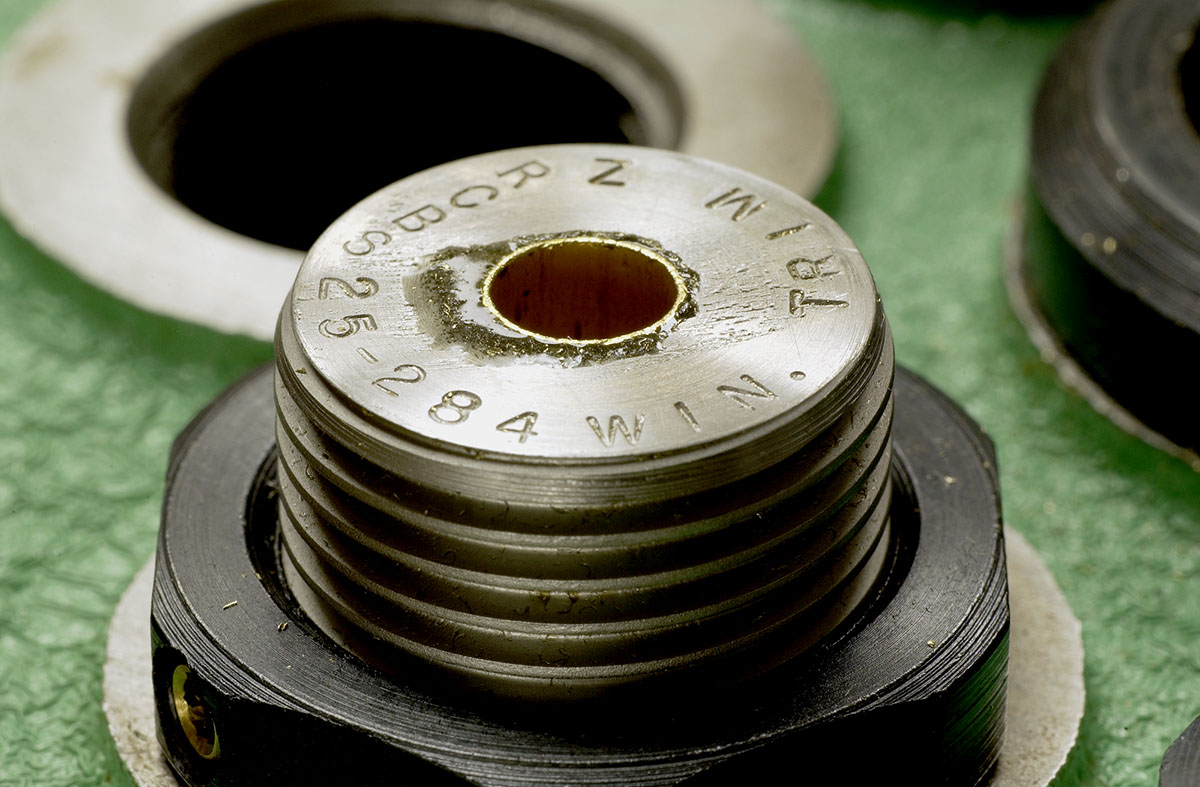

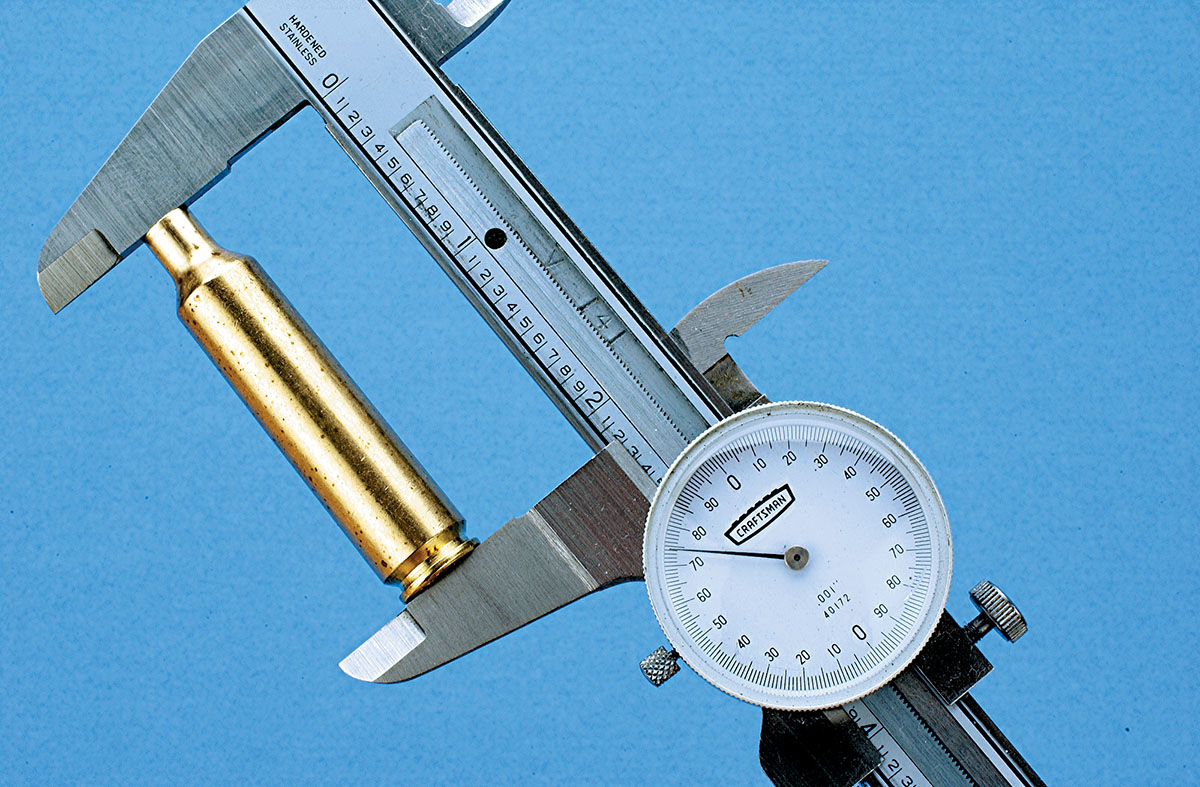

Start with standard .284 Winchester brass and go from there.

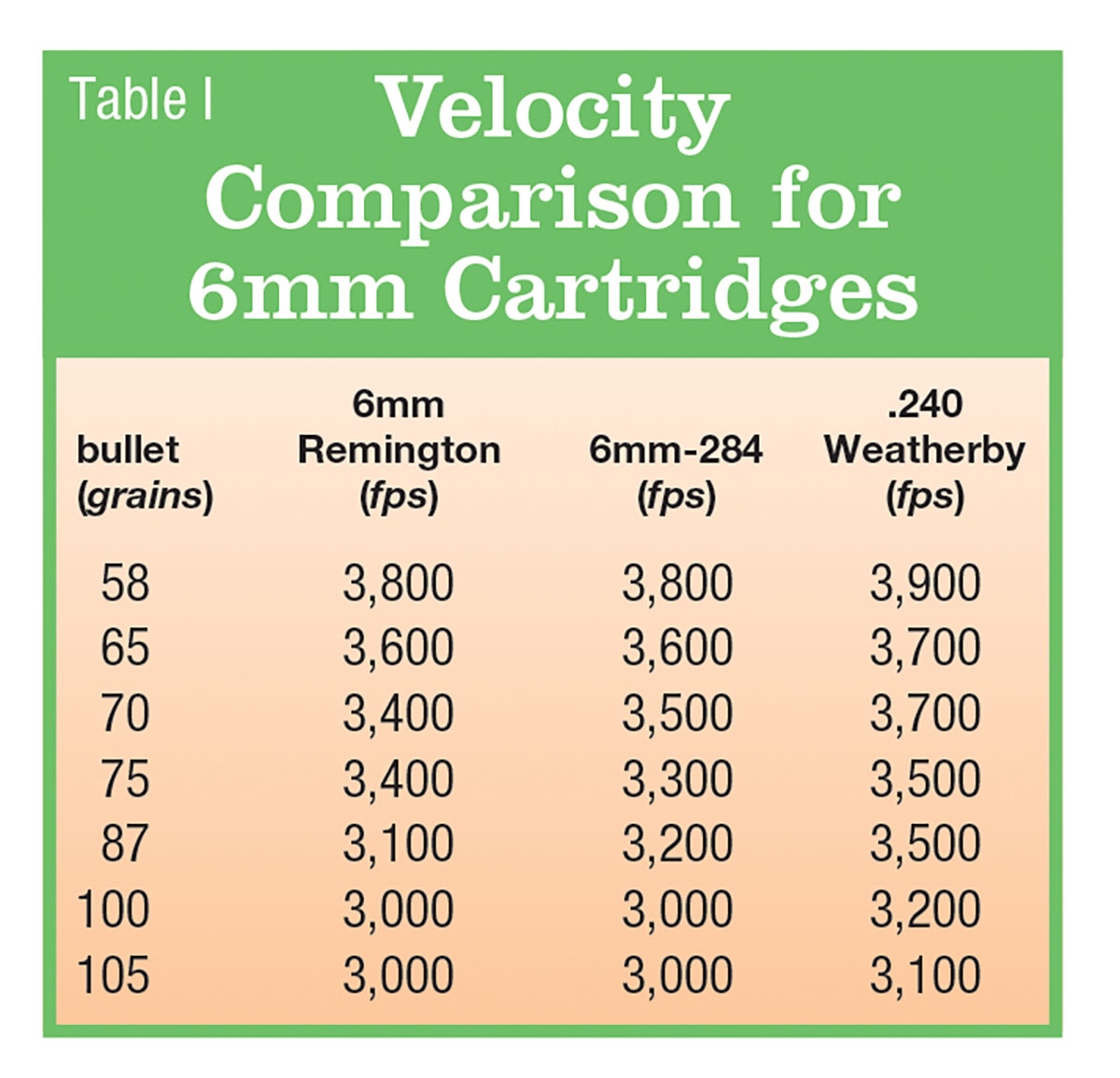

The other concern: Would it be too close to the 6mm Remington or the .240 Weatherby to be worth the effort? Actually all were very close, but the 6mm-284 leads the pack in case volume. The 6mm Remington has a boiler room capacity of 55.0 grains of water, the .240 Weatherby has 61.6 and the 6mm-284 holds 65.3. Does this mean the 6mm-284 is faster or more efficient than the others?

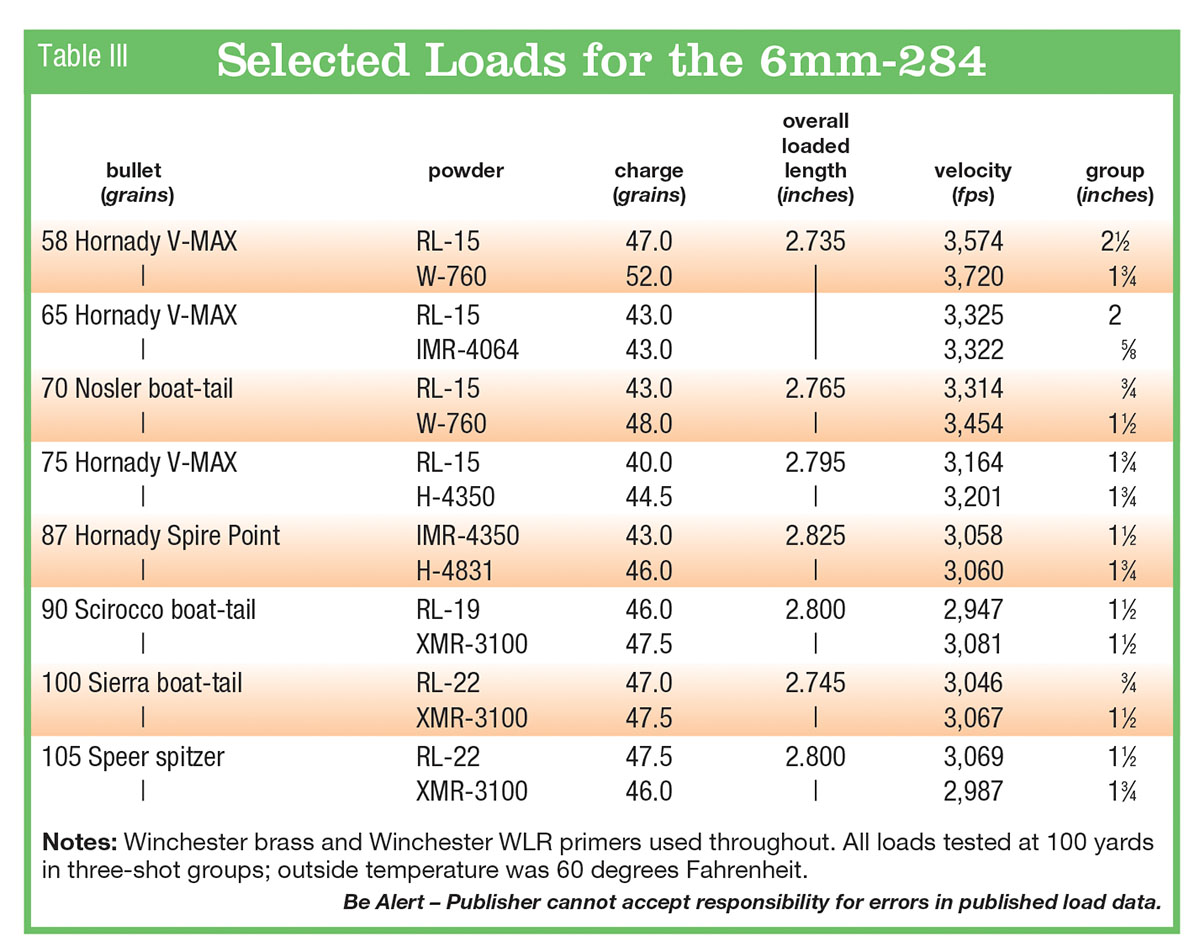

Not exactly. If we look at the velocity comparisons in Table I, the race seems to bounce back and forth between the 6mm Remington and our wildcat, but it was no contest when it came to the king of the six-millimeters, the .240 Weatherby. For instance, the 6mm Remington held its own against the .284 variant in the 58- and 65-grain bullets, dragged a bit on the 70-grain bullets, pulled ahead with the 75-grain offering, dropped 100 fps on the 87-grain bullet and remained just about even when it came to the 100- or 105-grain projectiles.

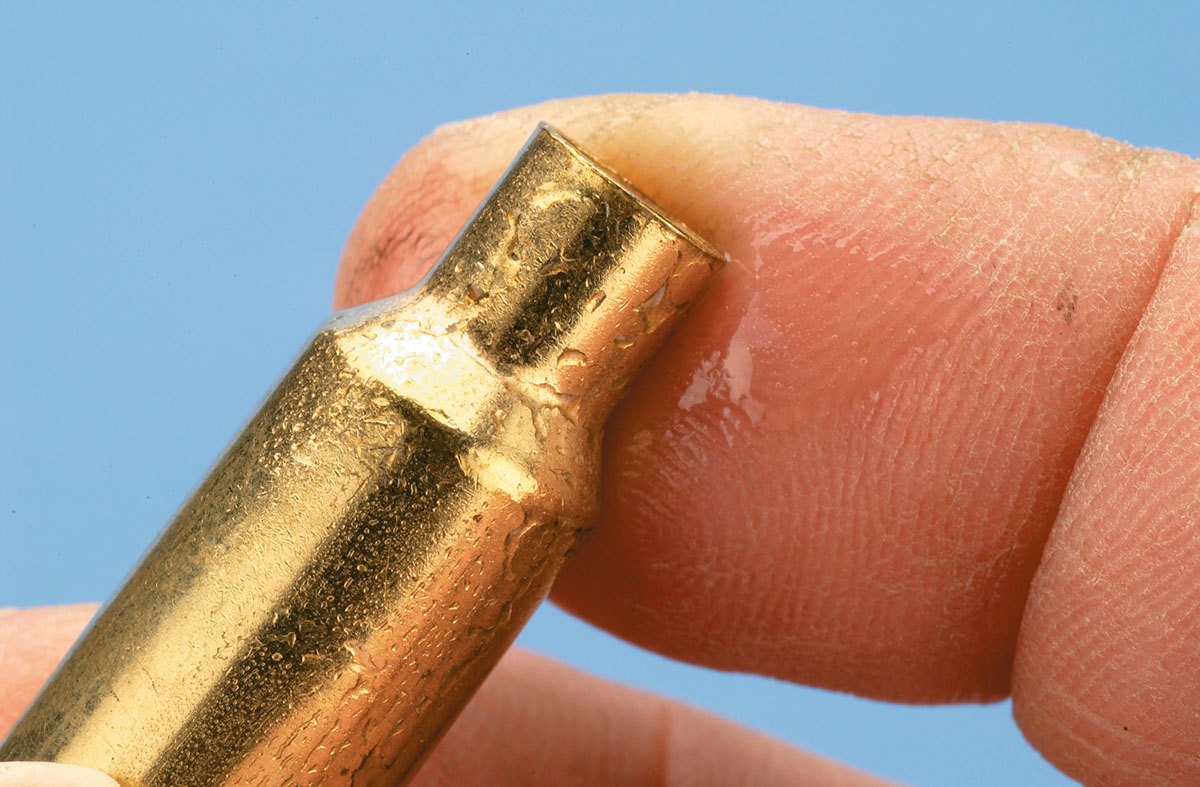

The case on the left is shown as the first step from .284 to .257 inch, while the case on the right was neck sized only after firing.

A loaded 6mm-284 and a fired case ready to be neck sized.

The one important fact to remember is that test firing with the 6mm Remington was with a 22-inch test barrel; with the 6mm-284, shots were fired in a 24-inch tube. If we factor all that in, and push comes to shove, both are so close that there is really not much to debate. Still another option is to wait for the final testing under actual conditions with

your gun and

your handloads.

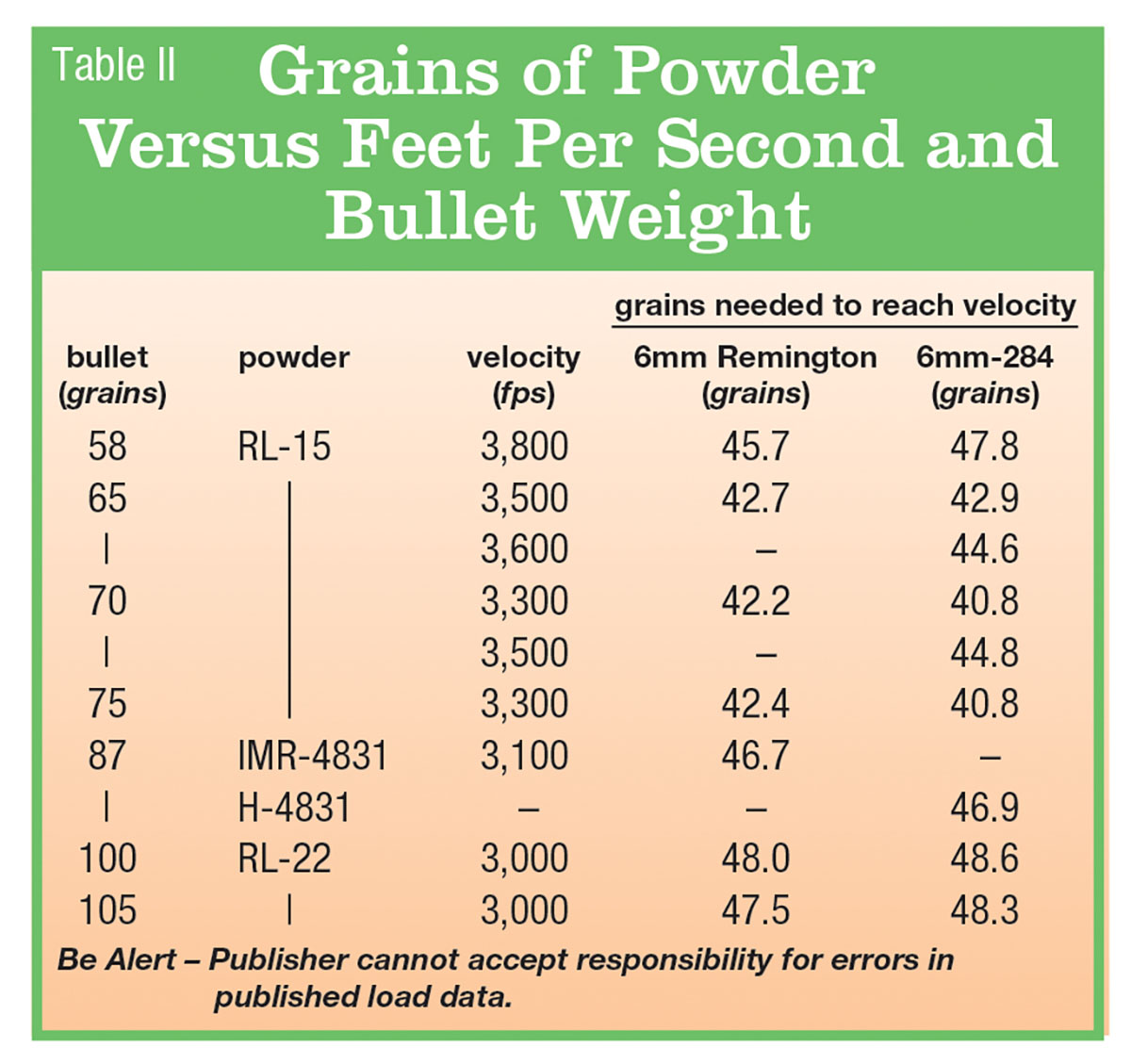

Is one more efficient than the other? Again, we start to split hairs with most of this coming from the internal volume and the makeup of the case. I’ll cite a few examples in Table II, only because the list is too long to include every powder or bullet combination.

Again, the ball goes back and forth, and in most cases (on paper only) it turns out to be a dead heat. In some examples (see Table II), the 6mm Remington beats the competition by only tenths of a grain; in others, the 6mm-284 goes two grains better. For the sake of argument, why would anyone even remotely consider the 6mm-284 over the 6mm Remington or give up the advantages offered by the faster kid on the block, the .240 Weatherby Magnum?

For one, the .284-based wildcat seems to be adaptable to a short action (without the .243 even considered here) only because the case is shorter, as is overall loaded length. Another reason is that I personally find the 6mm-284 more receptive to my personal use and parameters. Besides, it’s a real live “wildcat,” offering a challenge to the serious handloader who wants to try wildcatting without placing a second mortgage on the house.

Meanwhile, back at the loading bench . . .

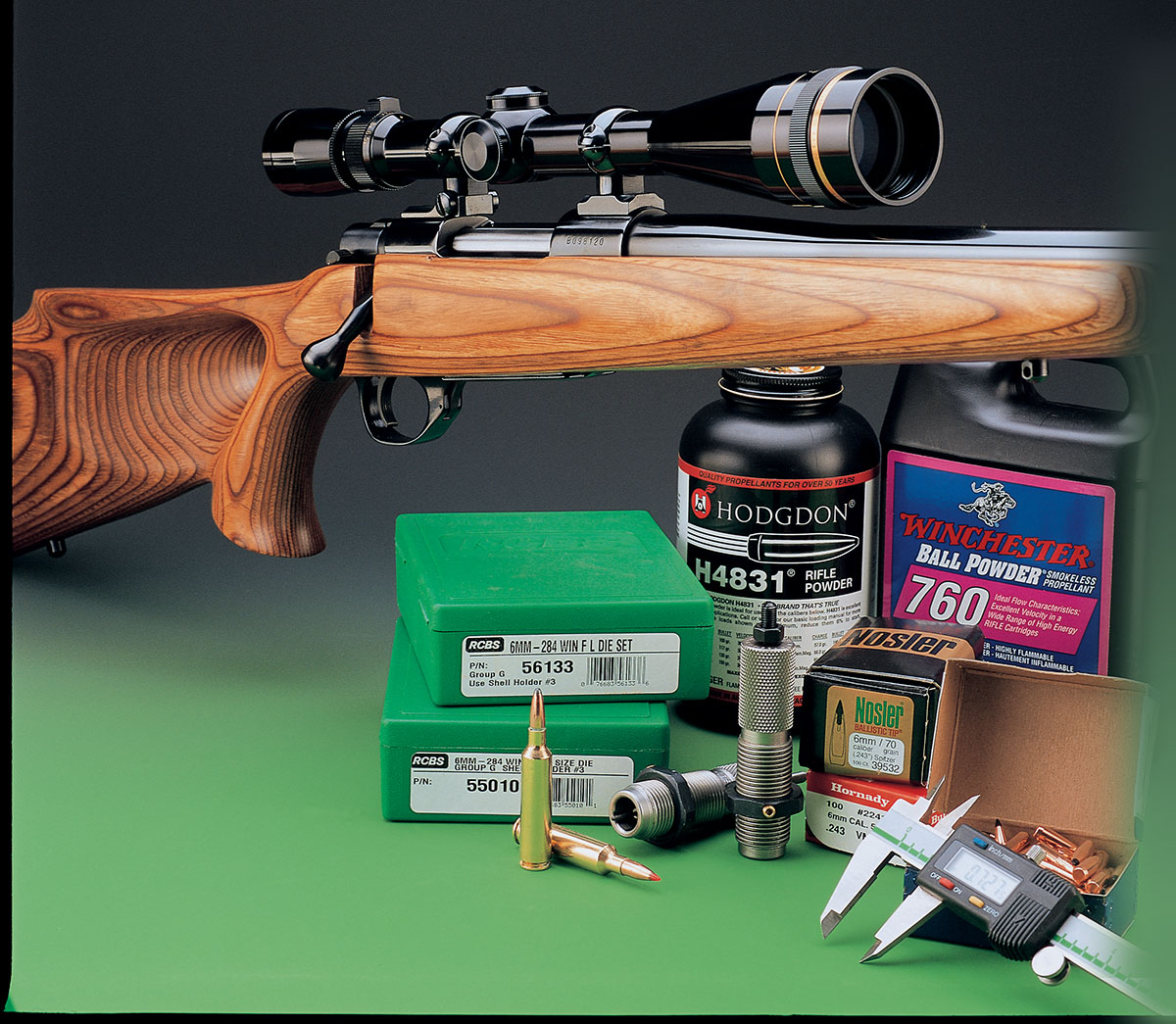

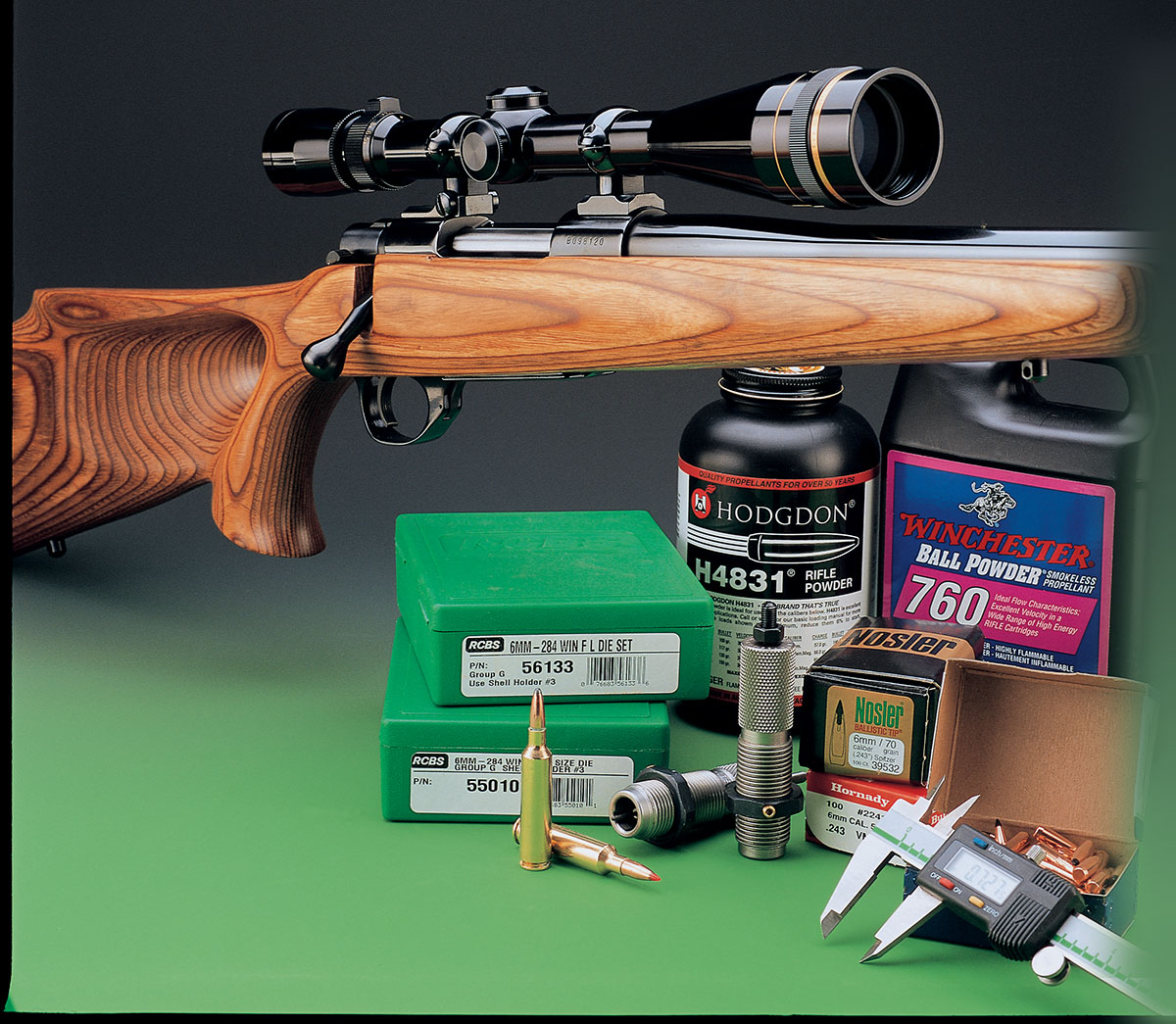

With all that aside, reloading is next. When looking for brass, it soon becomes obvious the parent .284 Winchester case is not easily found. It’s hard to understand simply because this case has probably sired more wildcats than most others combined. For a wildcatter, this is an ideal scenario: a case without a “magnum” belt that has in the past been necked from .22 upwards in just about every configuration possible and all without much effort. In any event, Winchester still makes it, and you can purchase it pres-ently in “consumer” packs or bulk.

Cases should be trimmed to 2.160 or 2.165 inches.

Primer selection for this case is the stan-dard large rifle, and I’ve never found the 6mm-284 wanting for something hotter (magnum), so anything along the lines of the CCI 200, Remington’s 9

1⁄

2 or the Winchester WLR should offer good performance in the field.

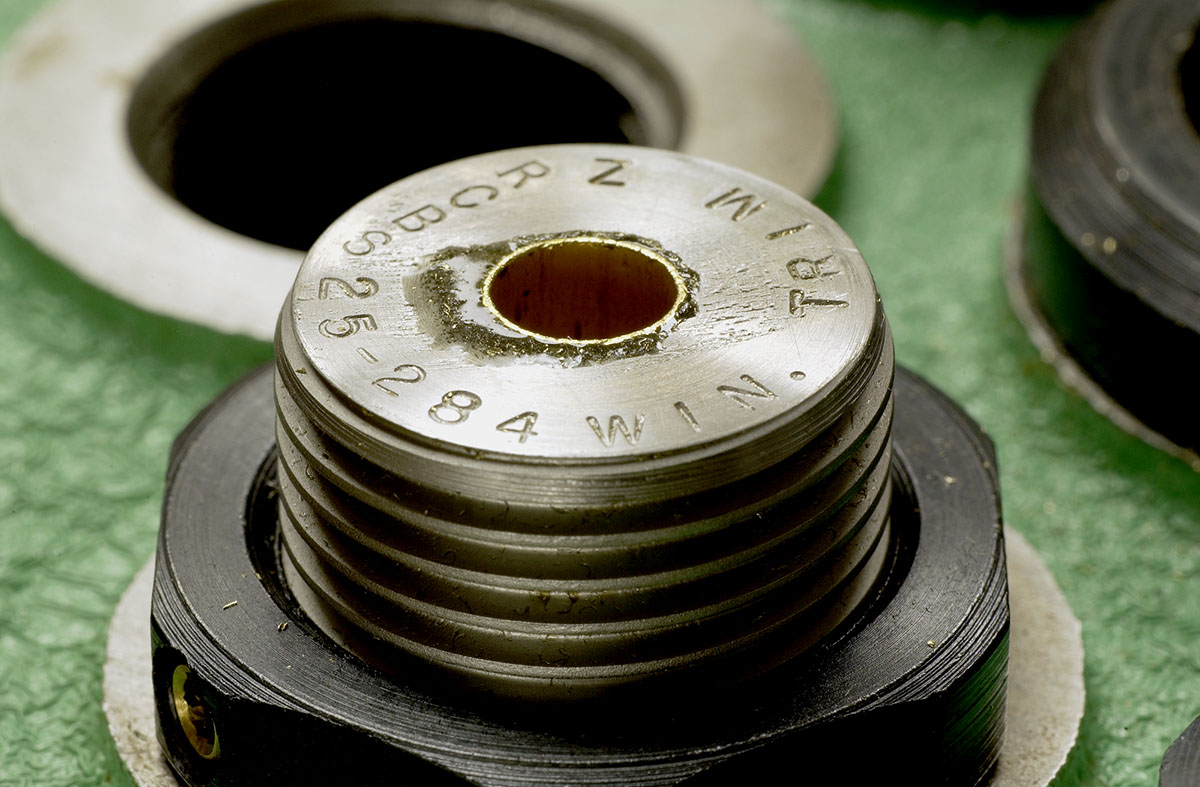

Case preparation is easy when loading for the 6mm-284. Assuming an adequate supply of .284 Winchester brass, the next requirement is a good die set. Here you’ll need a few extra items to improve the quality of your reloads. From RCBS, the first item you’ll want to order is its 6mm-284 full-length die set, part number 56133. Then, to take that .284-inch neck dimension down to .25 caliber for the first stage, an interim trim die (58090) should be added to the order. Finally, to neck size all the cases after the initial fireforming, order RCBS Neck Size Only die, number 55010. To complete the package make sure you have the common (.30-06 case head size) number 3 shellholder.

Stan set up the trim die, full-length sizer, neck sizer and seater. The neck sizer was used only after the case was fired.

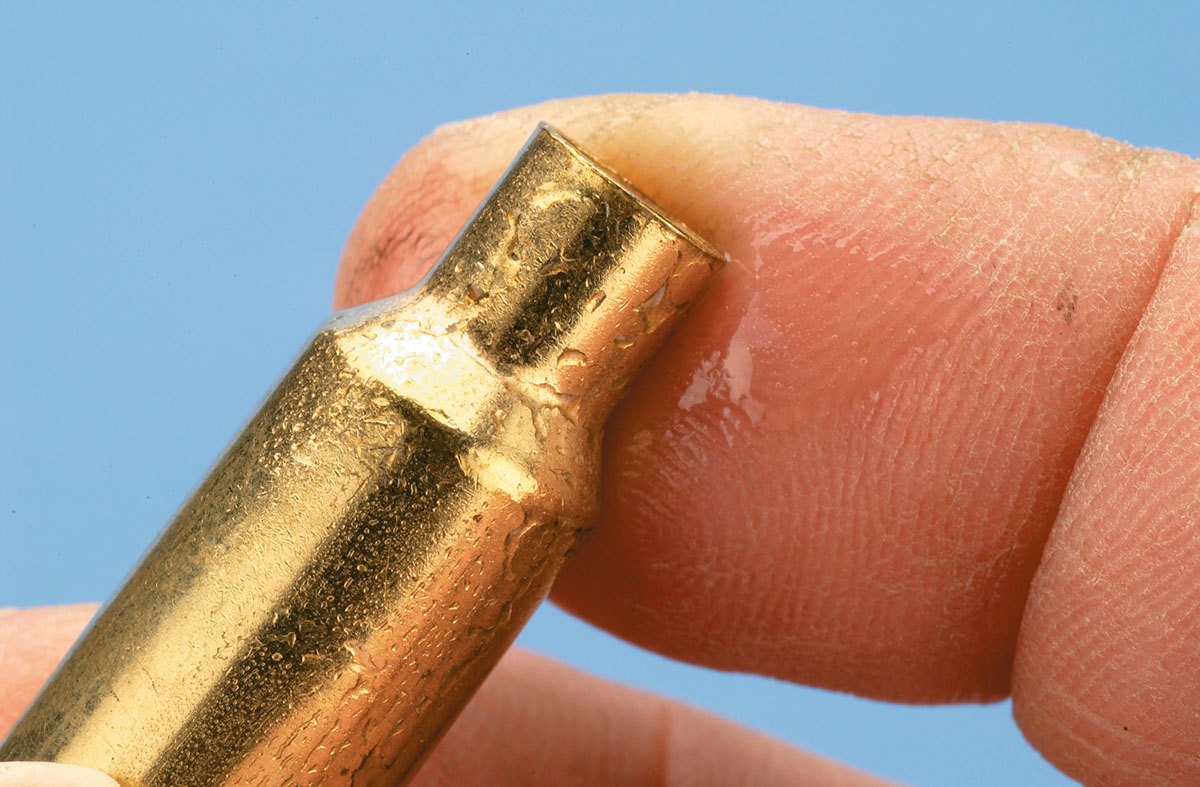

The best way I’ve found to work with a cartridge that needs a series of steps to get it to the final dimensions is to work in stages and finish each one before moving on to the next. I work with about 100 cases at a time, and with the 6mm-284 the first step after rolling each on the lube pad is to run each case through the trim die. This will get the case mouth down to .25 caliber (.257 inch), which then makes it much easier for each case to enter the full-length sizing die later. Many might question this wisdom, but just running the case through the 6mm-284 full-length sizing die is too intense for the neck of the case, resulting in an unwanted bulge just forward of the shoulder.

After 100 cases are run through the trim die, make a new pile and run the whole batch into the full-length die and measure a few for overall length. If you did everything right, the micrometer should read 2.170 inches. The trim die stretched the case to around 2.173 inches and the full-length die to 2.177 or even 2.180 inches.

To start the process of necking down, a small amount of lube is placed on the case neck.

For proper chambering and allowance for further sizing and finishing, trim the whole bunch back to 2.160 inches. For speed I use an RCBS Trim Pro motorized case trimmer and then clean them up with both an inside and outside chamfer of the case with its very novel Trim Mate. This is quite a bench tool to have around; not only does it make final preparation easy, but there are also tools that include military crimp removal, primer pocket cleaning and brushes to facilitate inside neck lubrication for an easy ride over the expander in the full-length sizing die.

The next step is to size the neck to .25 caliber.

Over the next two weeks, I spent some off-time fireforming 100 cases with 40.0 grains of Alliant’s Reloder 15 topped off with Hornady 75-grain V-MAX bullets. This is a good load for such a task

and besides being accurate helped in sighting in the Leupold scope, thus saving time and effort when serious range time came later. Back home, cases were inspected, necked sized and cleaned. Then the whole batch was primed with Winchester WLP primers for the second go-round.

Bullets included selections that I’ve had good luck with when dealing with the .243 Winchester and .240 Weatherby Magnum. Most brand names are represented, and for a good mix I’ve even included a recent Swift Scirocco boat-tail. Overall loaded lengths (OAL) shown in the tables are for rounds seated in my rifle only and are meant for use as a guide or starting point. Always make up a “dummy” round for trial chambering and for record later on.

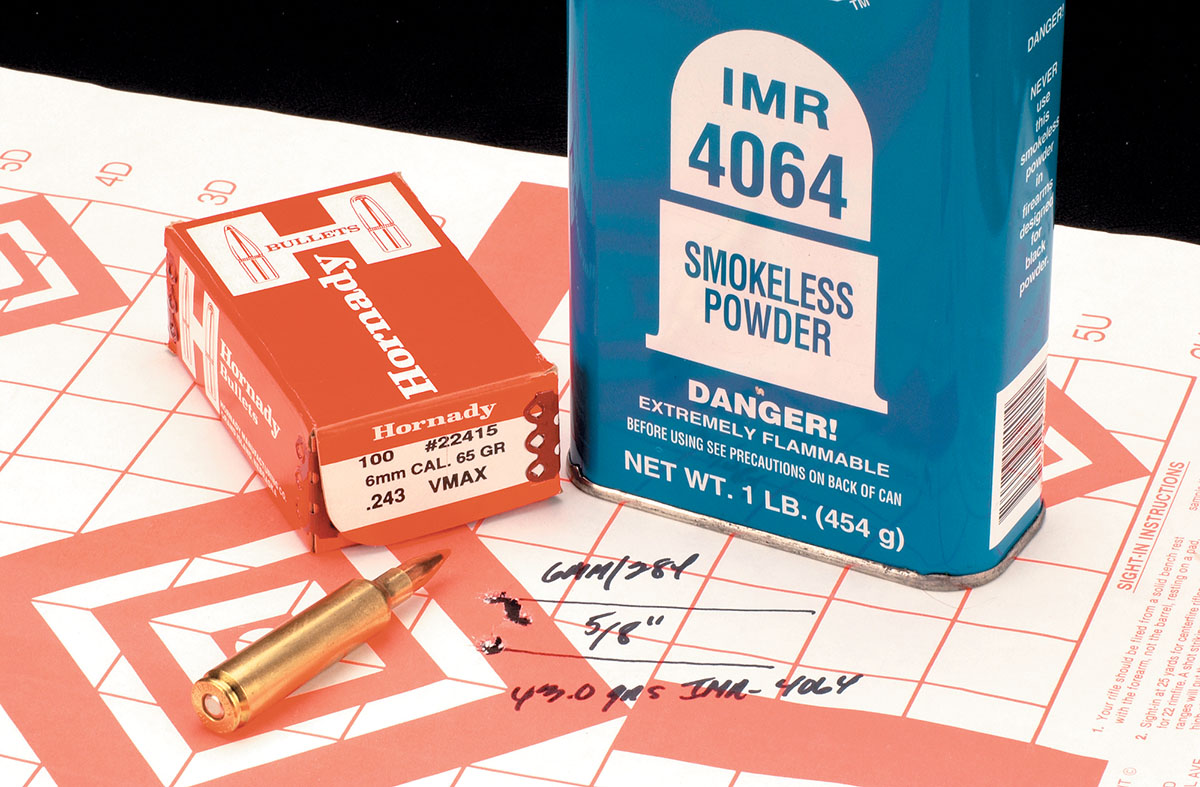

Powders were all in the fast/ medium range for the lighter bullets and medium/slow in the heavier weights. If I were making up a lot of loads for extended varmint shooting sessions, I’d opt for easy flowing RL-19, RL-22 and Winchester 760. Other possible selections include IMR-4064, H-4350 and IMR-4350.

Home on the Range

The 6mm-284 is a good cartridge to shoot, and like any other 6mm caliber, the recoil is short, pleasant and easy on the shoulder, even with extensive load testing. Overall, the 6mm-284 is consistent, delivering good downrange performance.

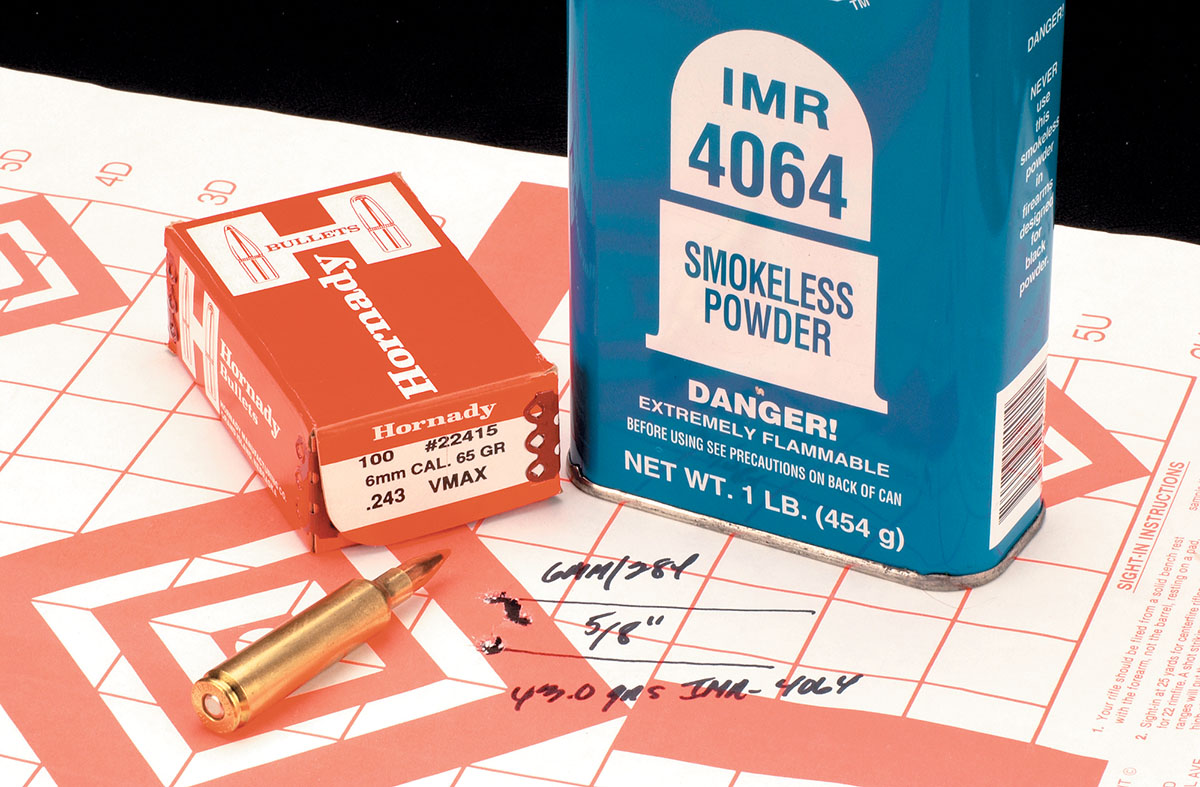

The 65-grain Hornady and IMR-4064 grouped under an inch.

Discarding any of the groups below an inch and over 2 inches, my average for the day was 1.61 inches. Naturally there were exceptions, and most came with the groups that were under an inch. The smallest of the morning was

5⁄

8 inch with a 65-grain Hornady V-MAX over 43.0 grains of IMR-4064. Velocity was 3,322 fps, but notice how close we are to the load with the same bullet but with 43.0 grains of RL-15 – only 3 fps between each – but observe the difference in group size, almost three times as large with RL-15 versus IMR-4064. Then again, the 70-grain Nosler boat-tail with 43.0 grains of RL-15 shoots quite well. Another Reloder powder combination features a Sierra 100-grain boat-tail over 47.0 grains of RL-22 for a velocity of 3,046 fps and groups under an inch. This could be the perfect pronghorn load.

The Sierra 100-grain boat-tail backed by 47.0 grains of RL-22 is a fine load for medium plains game.

Still another close race is seen between those loads tested with the Hornady 87-grain Spire Point where the difference between IMR-4350 and H-4831 is too little to talk about. The 90-grain Scirocco, according to its spokesperson, takes this “bonded core and state-of-the-art shape that delivers buck-bragging energy clear out to the county line.” With a thick jacket that assures 80+ percent weight retention and ample penetration, it makes the .243 caliber nearly perfect for those who are interested in a low-recoiling, big game rifle.

Stan found the thumbhole stock very comfortable to hold and shoot, even in a variety of positions.

Back home all the cases were examined for excess pressure or other potential problems. With just about 100 cases sized and fireformed for the 6mm-284 there was nothing in the way of extractor marks, excessive stretching or enlarged primer pockets. Only one load – 47.5 grains of Accurate’s XMR-3100 under the 100-grain Sierra boat-tail – showed any sign of pressure and that related to a moderate bolt lift after firing. The maximum in the Hornady book is 48.7 grains of XMR-3100, and my load is still safely below that. All bullets in this load were seated at 2.745 inches, which is below the book’s recommendations of 2.825 inches. In any event, dropping the charge down to 47.0 grains cleared up the problem with only a slight drop in velocity.

The 6mm-284 is fun to work with, and with the help of folks like E.R. Shaw and his barrels and Randy Boyd’s great stocks, it remains an out and out pleasure. For sure this rifle and cartridge will get the nod for varmints and larger plains game, and I will continue to fine-tune those loads for smaller groups.

I asked the question in the beginning if the 6mm-284 would be worth the effort? Yes, it is, and it’s an easy wildcat to get involved in.