6mm Remington Ackley Improved

Optimizing the BIB 95-Grain Flatbased Bullet

feature By: Jason Stanley | April, 24

We had just navigated the turn onto Interstate 90 East when I asked Randy a loaded question; “What would be the perfect coyote bullet?” The immediate reply emphasized his confidence; “My 6mm, 95 grain, flatbase.” The remaining two hours of road time was spent listening to justification for the eleven-ogive bullet.

For those who have not had the pleasure; Randy, or RG as his friends call him, is a living legend in the world of precision shooting. He is a member of the elite Hunter Class Hall of Fame and was instrumental in the birth of the 30 BR cartridge. RG is also the proprietor of BIB Bullets. Randy’s bullets have accounted for more NBRSA and IBS (International Benchrest Shooters) National Championship wins, records and hall of fame points earned than any other bullet. A secret, known mainly in the Benchrest community, is Randy also makes great hunting bullets.

To nobody’s surprise, Randy swept the Hunter class portion of that weekend’s tournament, becoming the first back-to-back Wisconsin State Hunter Champion. I finished somewhere in the middle of the pack. To my surprise and everyone else’s disappointment, I was lucky enough to win a free Lilja barrel in the prize drawing. This provided the perfect conversation starter for dinner on Saturday night.

The Build

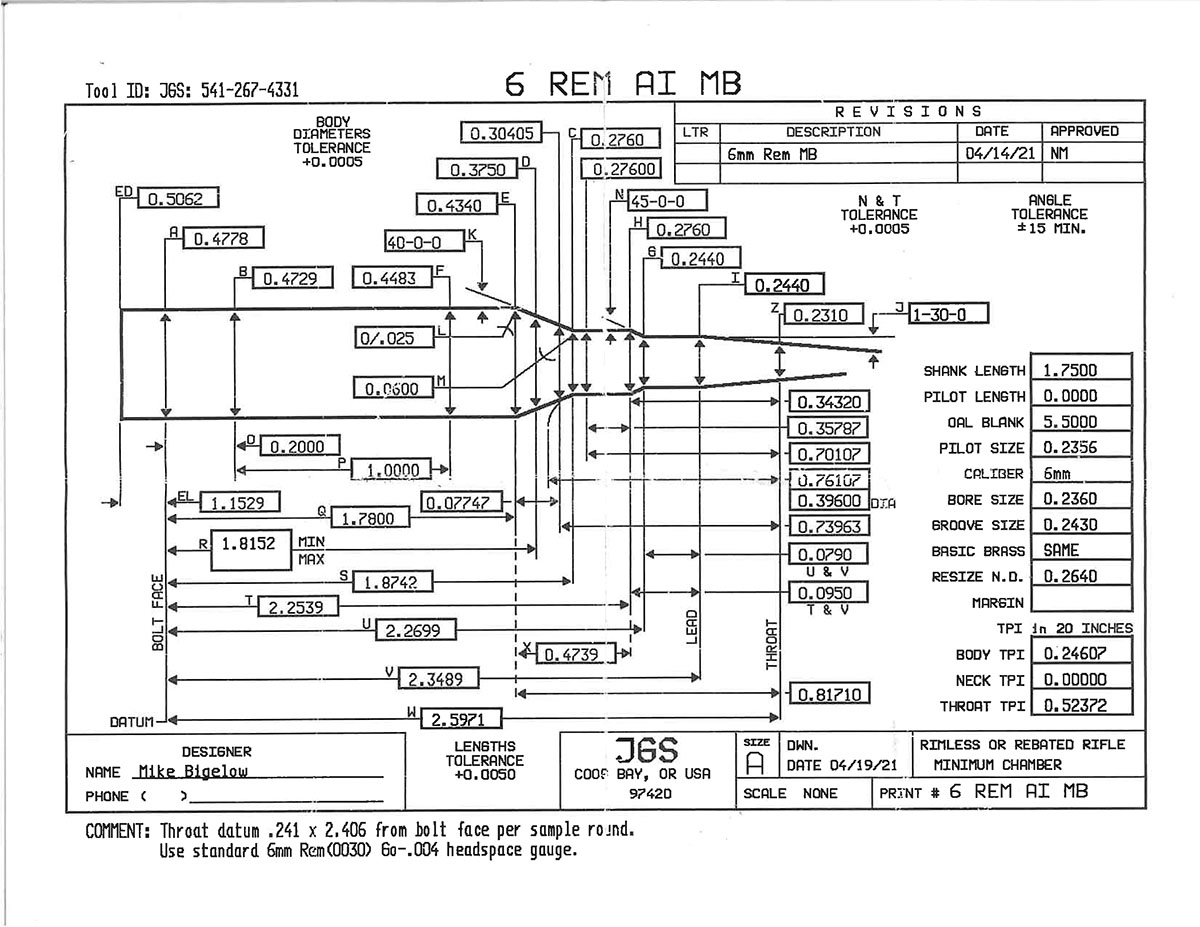

The combined efforts resulted in a 6mm Remington Ackley Improved chamber. This chamber would be cut into a 25 inch, number five contour, 1:9 twist, stainless steel barrel from Dan Lilja. Theoretically, the union should propel the 1.075-inch bullet north of the 3,500 feet per second (fps) mark, producing a gyroscopic stability factor (Sg) of 1.6 safely above the minimum 1.4 needed to stabilize a bullet.

Over the years, while eavesdropping on conversations at various tournaments, I have heard great things about Defiance Actions. This was the perfect build to give one a try. A phone call to Cody Hart at Defiance Actions led to the Tenacity medium-length action. The Tenacity would be a right bolt, right port with a .308-inch bolt face. The correct fit for the roughly, 3-inch cartridge.

Finding a bed for the action was one of the more challenging aspects of the build. My usual go-to stock manufacturers did not offer inletting for the relatively new medium-length action. A properly done inlet saves Mike a lot of time, making my bill smaller. Several hours of research led to the McMillian Game Warden Stock with machined aluminum pillars. Molded in color patterns that were chosen to blend into grassy fence lines where much of the hunting will be. The 1-inch decelerator pad finalized the length of pull to 13.5 inches.

Another prize drawing, this time at the NBRSA Nationals, allowed me to use 30mm rings from Greg Swezey at Gold Creek Rifles located in Carlton, Washington. Resting snuggly in these impeccable rings is a Sightron S-Tac 4-18x.

Hanging underneath, ready to fire the round, is a Timney trigger set at a crisp 1 pound, 8 ounces. The total package, including the sling, weighs in at a manageable 10 pounds, 7 ounces.

I picked the completed rifle up from Mike in February 2023. The “lion’s share” of the extended project time was due to COVID-19. The total out-of-pocket cost was under three grand. That is not bad for a fully custom-hunting rifle that will be passed down to future generations.

Fireforming/Brass Work

No uniforming or trimming was necessary as all Remington brass cases were safely under the maximum case length of 2.254 inches. Essentially, case neck chamfering and deburring was the only pre-fireforming work done, allowing easier initial bullet seating.

Due to the 40-degree shoulder in the chamber, an adjustment was needed to the standard fireforming procedure. Instead of the typical .005-to-010-inch shoulder bump, a .003-inch crush fit was desired. Bigelow did a great job of designing the reamer, so no shoulder adjustments were needed on the virgin brass.

Rummaging through my stash of bullets produced half a box of 6mm Nosler 70 grain Varmageddon bullets. Mike had some old (World War II age) IMR-4831 powder that would work well for blowing out the shoulders. Fifty grains of this original powder provided a nice pillow for the Nosler bullet seated .025 inch into the lands. The level of powder and seating depth combined with .004 inch of neck tension helped keep the bullet from being pushed back into the case when chambered. The relatively hard bolt closing confirmed the base of the case was being held tight against the bolt face, ensuring a crucial step in the fireforming procedure. This resulted in the shoulders being mostly formed during the first firing.

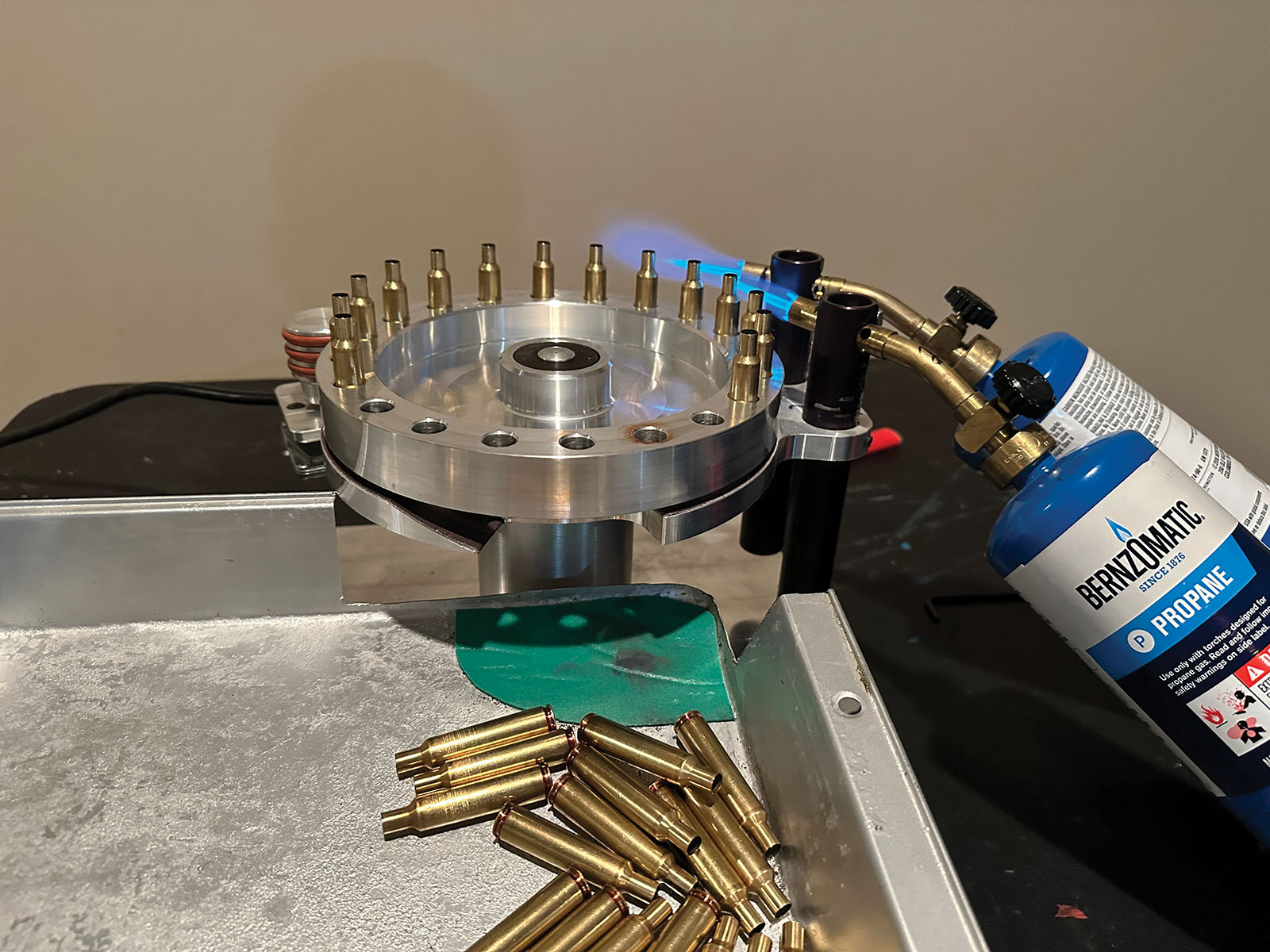

The amount of initial brass movement significantly increased the effects of work hardening. After the initial firing, all the brass was annealed using the Ken Light Annealer. This procedure helped certify the complete formation of the shoulder during the next two firings.

After the second firing, all brass was uniformed to the shortest case, which was 2.215 inches using a Wilson trimmer. This is well under the standard .020 inch, usually trimmed to from maximum case length. The necks were then chamfered using a Wilson 45-degree deburring tool. Deburring the outside of the necks was effortless for the RCBS Case Prep Center. A Sinclair Large Rifle primer pocket uniformer was the tool of choice for uniforming the primer pockets. An RCBS flash hole deburring tool was used to clean up the inside of the flash holes to finish the brass work.

Tuning

For “new to me” cartridges, I like to start with load ladder tests at 200 yards. Each ladder has two goals: first, quickly find a powder/bullet combination that delivers the desired velocity without showing signs of pressure. Second, indicate a general range of powder charges that show precision with the chosen bullet. Powders that showed promise in both categories would be given more attention with groups at 100 yards.

All bullets were initially seated .005 inch into the lands, averaging an overall loaded length of 3.046 inches. Holding the bullets tight was .0037 inch of neck tension provided by a .270 bushing. Erroring on the side of caution, charges were started low and then increased by .2 grains until pressure signs indicated to stop.

The first powder tested was Hodgdon H-4831 Short-Cut. Using 48.4 grains of this powder started the load ladder. Charges were increased until 50 grains was reached, producing a mediocre velocity of 3,337 fps. Equally disheartening, no bullets were remotely close to touching. To save my depleting supply of CCI BR-2 primers, one round was loaded at 51 grains. This load produced a sticky bolt lift and a modest velocity of 3,417 fps. All arrows were pointing to try a different powder.

A local benchrest tournament revealed a gentleman who was selling unused powder. I was able to snag three-quarters of a pound of 2006 Reloder 22. Using 51 grains of this powder the second ladder test was started. This bullet/powder combination showed grouping promise around the 51.6 to 52 charge range along with the desired velocity between 3,550 and 3,585 fps, respectively.

A multitude of “two and one” groups were fired with charge weights between 51.6 and 52 grains. Commonly, split groups are an indication of slightly high pressures. Different bushings were used, along with decreased seating depths to lighten this pressure. Groups did tighten but were still split. There was another perplexing issue; these charge weights would shoot a decent group one day, but the next day, the group would open and be accompanied by pressure signs. Although Reloder 22 produced excellent velocity and was shooting acceptable groups, I was getting annoyed with expanding primer pockets ruining the brass and moved on to another powder.

Due to the enticement of the excellent velocity, I did not want to “abandon ship” on HV100. Historically, I am not a fan of two-shot groups. However, in this case, the technique had merit. I wanted to save primers and barrel life. If two bullets won’t touch, then neither will three. HV100 produced great velocity, but the rifle simply did not like what it was being fed.

Frustration was settling in. I decided to deep clean the rifle and let it sit for a couple weeks. The 2023 NBRSA Score Nationals were quickly approaching, and this distraction was not welcomed.

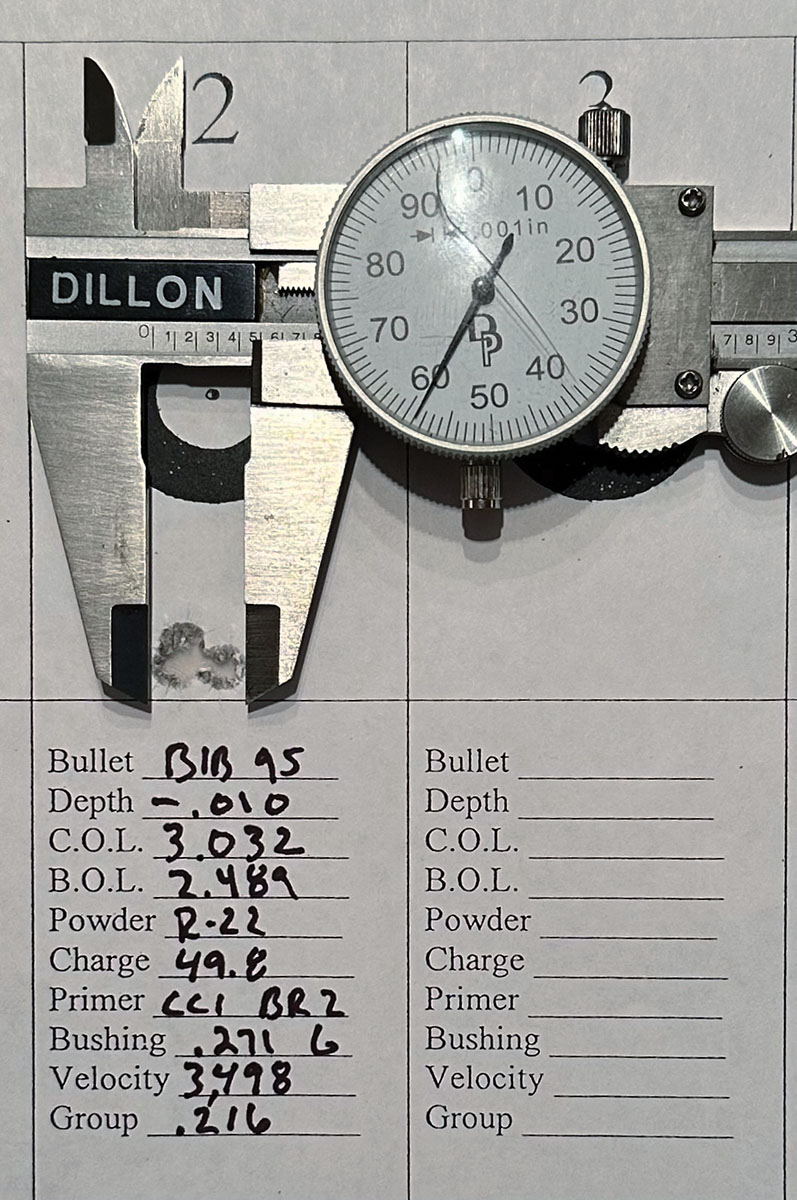

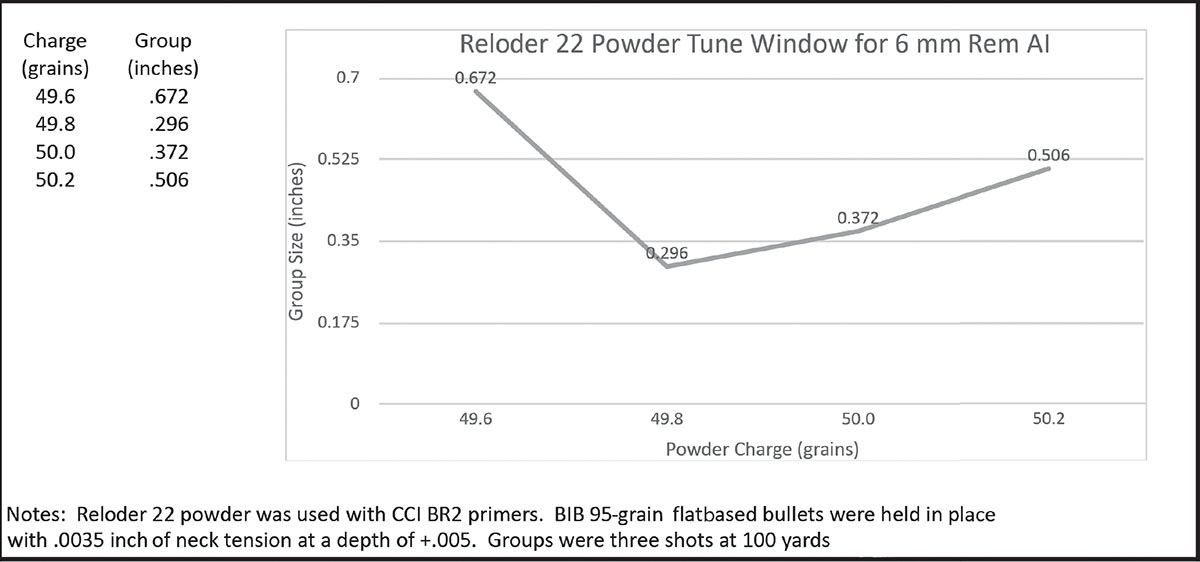

The “time away” allowed me to see what was right in front of my face the whole time. Reloder 22 wanted to shoot. I was blinded by the need for speed. Lighter charge weights of Reloder 22 were tried. Velocity decreased as expected, however, the door to a new level of precision was opened. The accompanying graph shows the powder charge tune window that I was searching for as 49.8 grains was confirmed by an additional .332-inch cluster while still averaging 3,493 fps.

Validating the powder charge meant it was time to focus on seating depth. The just touching point, .000 inch, produced a bigger, yet still acceptable, .509-inch group while -.010 depth produced a beautiful .216-inch knot and -.020 produced an impressive .241-inch group. As a result, -.010 earned a spot in the starting lineup as the longer seating depth provided a cushion when the lands begin to erode. The repeatability of the charge weight combined with seating depth fine-tuning confirmed the combination to run this hunting season.

Speed and precision are the ideal combination for a predator rifle. In this case, I traded a morsel of speed for an increase in precision. Many of my shots are under 300 yards, which made the trade acceptable. Plus, 3,500 fps isn’t exactly slow for a 95-grain bullet.

Theoretical Ballistics

The windage is equally impressive. Using the online Bison Exterior Ballistic Calculator, a 10 mile-per-hour crosswind will deflect the bullet a mere 1 inch at 200 yards and 2.5 inches at 300 yards. Again, this is easily within the ability to hold. This spring, I will perform real-world drop tests.

Even though many of my shots are considered “close,” the 6mm Remington Ackley is designed to reach out when needed. I am confident there is more velocity to be gained without trading precision. Different powders, including Reloder 17 and Vihtavuori N-160, will be tried in the spring. For now, it is time to go hunting.

Results in the Field

At the time of this writing, five coyotes have been taken with this 6mm Remington AI. Daytime calling started in early October, roughly the same time the local crops were being harvested. Two males and three females have mistakenly responded to the Lucky Duck Roughneck call. The early season meant prey in distress ending with pup in distress were the main sounds used before the eternal sleep.

Shot distances ranged from 60 to 240 yards with most slightly over the 100-yard mark. Angles were head-on to 90-degree broadside. These are pretty standard shots for this area.

Much of my hunting is in response to coyotes being a nuisance to local farmers. Plus, there is currently no market for furs in southeast Nebraska, which makes pelt damage and the impressive exit wounds a non-issue.

In football, running backs take pride in the yards after contact (YAC) stat. This stat is also important in a predator rifle. Running backs want a high YAC number. The inverse is true for predator rifles. On four of the five coyotes, the YAC stat is zero. As Randy stated on our drive to Holmen; “A properly placed 95 will be bang…dead.”

Ironically, the smallest of the five coyotes, shot directly through the heart, managed to make it 20 yards. Tracking was easy as she left a blood trail a three-year-old could follow. It is a testament to the toughness of this animal and to the results of a quality bullet properly tuned.

About the Author:

Jason is a father, husband, avid outdoorsman and science teacher from Nebraska. He competes in short range benchrest throughout the Midwest where he has won multiple state and national championships. Jason is a freelance writer and content creator of ctdshooting.com and the YouTube Channel ctdshooting.