222 Remington

Modern Powders for an Early Varminter

feature By: R.H. VanDenburg, Jr. | April, 15

Developed by Remington’s Mike Walker, the cartridge’s unique characteristic was its size. Not based on any existing case, it had a case rim of .378 inch and a nominal dimension in front of the extractor groove of .376 inch. Case length was 1.700 inches. It was initially chambered in the short-action Remington Model 722 with a 26-inch barrel. The cartridge first attracted the attention of varmint hunters, as it was intended to do, but rapidly began to find favor among the truly accuracy-conscious benchrest crowd. Walker first used the cartridge in benchrest competition in the summer of 1950.

Gun writers of the day took notice, universally praising the cartridge. Warren Page of Field & Stream, Jack O’Connor of Outdoor Life and Townsend Whelen all noted the cartridge’s exceptional accuracy. Page used the cartridge to shoot his way into the Benchrest Hall of Fame. Bullets of the era were frequently made by the benchrest shooters themselves or purchased from individuals who made highly accurate projectiles. Weights for .22s were usually 50 to 55 grains but eventually seemed to settle on 52 or 53 grains. Today Berger, Sierra, Hornady and several smaller firms turn out match-grade bullets.

Among powders, after some shaking out, DuPont’s 4198 emerged as the powder for the 222 Remington. The most popular loads were 20.5 and 21.0 grains with bullets from 50 to 53 grains. Heavier 55-grain bullets sometimes were paired with the same charge but were often cut back to 19.5 or 20.0 grains. While both the 20.5- and 21.0-grain charges went on to earn classic status among handloading cognoscenti, a quick look at the most recent load data from Hodgdon, which offers 4198 under its IMR label (the former DuPont powder) and its own H-4198 (manufactured in Australia) shows these loads to exceed currently acceptable maximums.

It wasn’t long before the 222 Remington shouldered aside the previous benchrest darling, the 219 Donaldson Wasp, and reigned supreme, for the most part, until the advent of the next accuracy phenom, the 22 PPC. It, in turn, gave way to the present reigning champ, the 6mm PPC. The 222 Remington held on as the favorite moderate range varmint cartridge until it was steamrolled by the upstart 223 Remington. No one could argue that the 223 was more accurate than the 222; but it was, and is, our military cartridge, and everyone was chambering rifles for it.

With the growing interest in guns built on the AR-15, which is built around the 223/5.56 NATO, the 222 Remington has faded into oblivion. No major rifle manufacturer in this country chambers the cartridge any more, although many smaller manufacturers will chamber it on request. This is sad, perhaps, for the cartridge is as accurate as it ever was, has the same modest report and general range of usefulness – but time and the tide of public opinion wait on no one.

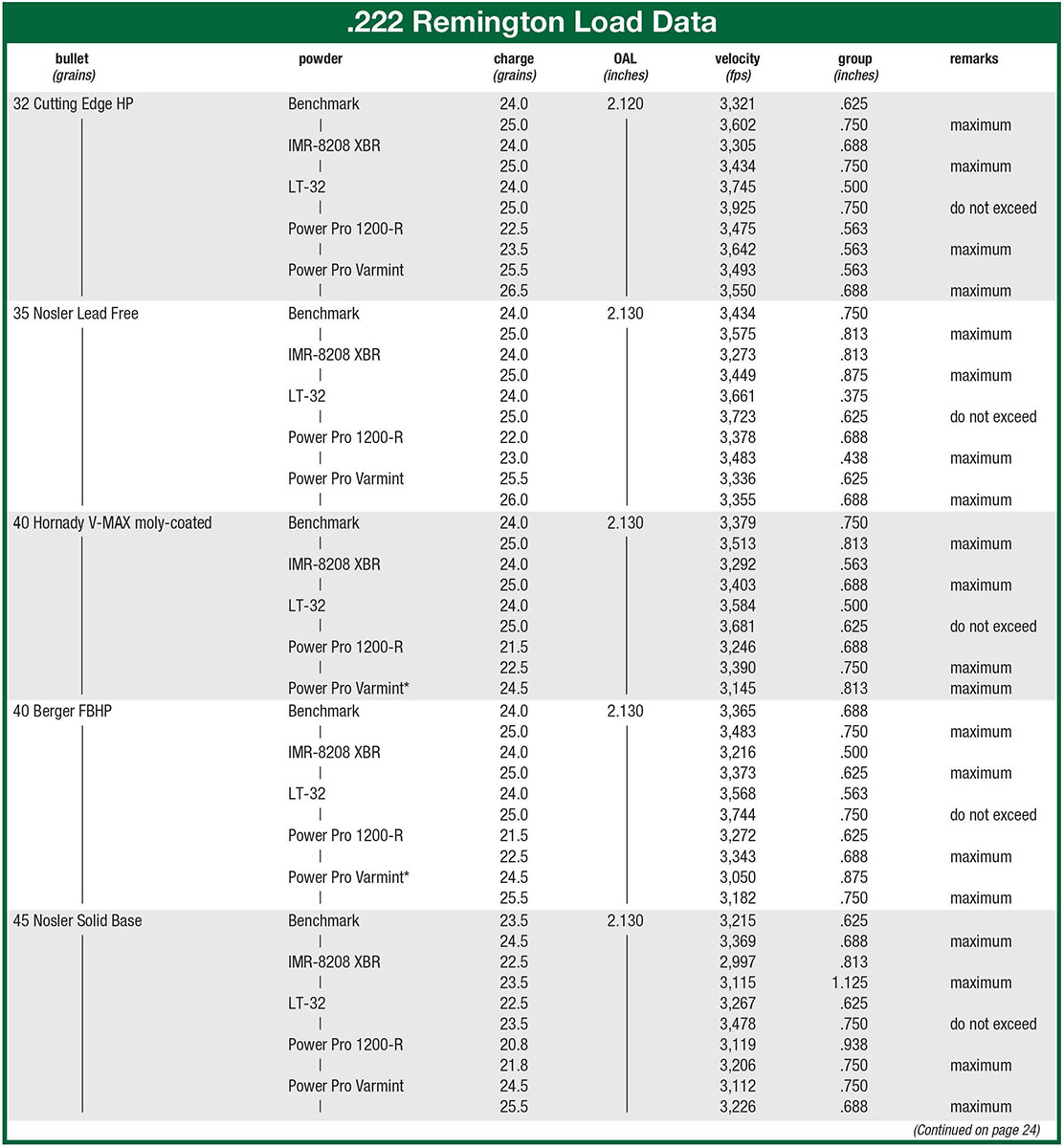

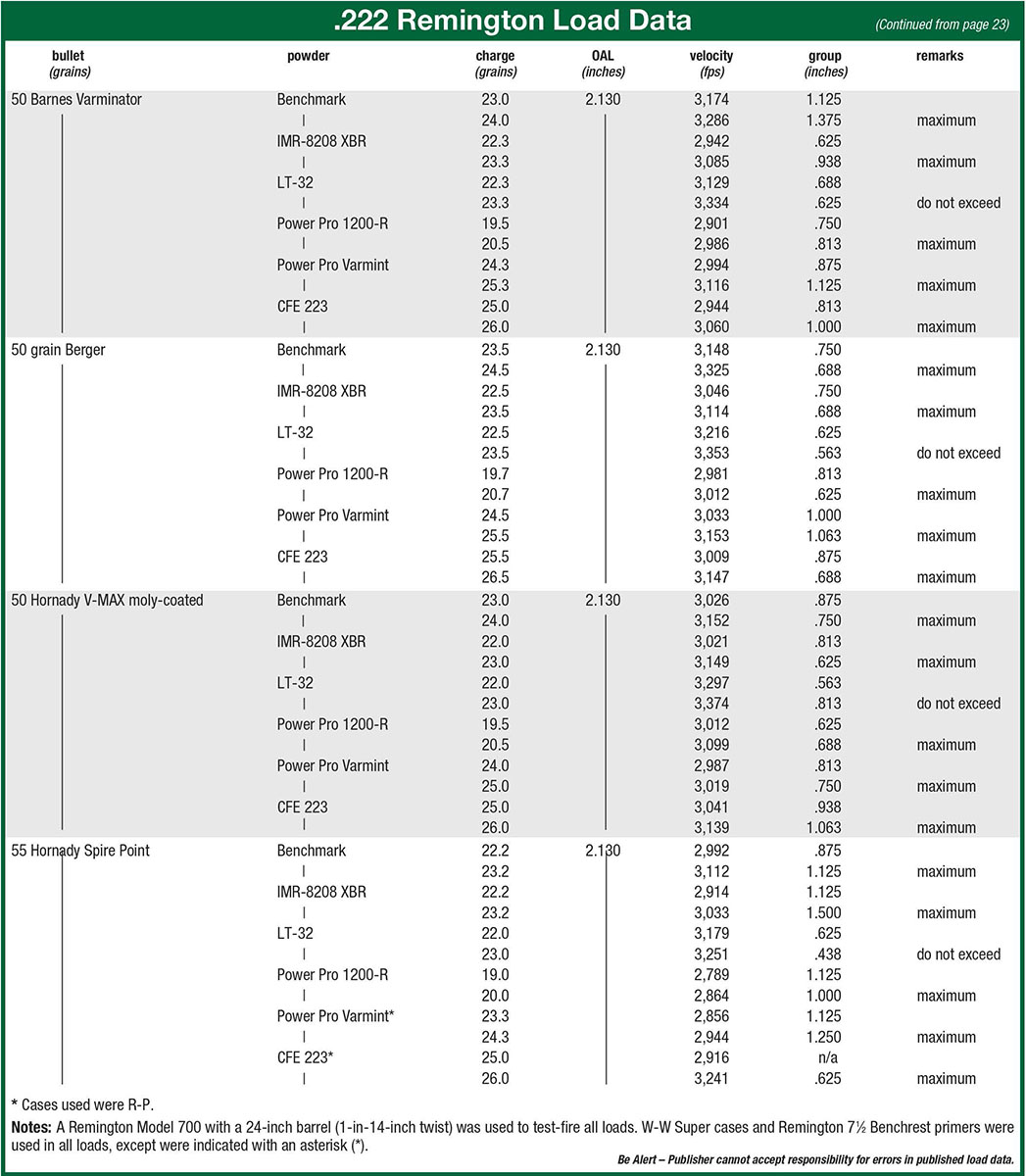

There are a full half-dozen powders that qualify as both new, or reasonably so, and suitable for use in the 222 Remington. Three are single-base, extruded powders: Hodgdon Benchmark, IMR-8208 XBR and Accurate LT-32. The other three are ball powders: Alliant Power Pro 1200-R, Power Pro Varmint and Hodgdon CFE 223.

Benchmark is the oldest of the powders included here, introduced about 2000. It is part of Hodgdon’s Extreme Series, meaning it is almost impervious to extremes in temperature. Manufactured in Australia by the then ADI, now part of the THALIS Group, Benchmark is a very short-cut powder having a burning rate slower than IMR-3031 and generally close to H-335. It meters quite well, burns cleanly and seems to enjoy success in Hodgdon’s lineup.

IMR’s 8208 XBR entry into this group is a fascinating story – far too long to be told here. A brief summary is that the Thunderbird Cartridge Company purchased large quantities of a government surplus powder manufactured by DuPont and offered it for sale as 8208. Walt Berger, of benchrest and bullet fame, purchased one lot of the powder and sold it as T32. As supplies of all of these were running low, Hodgdon was approached by several people to make more. It didn’t, but instead offered a new powder that was met with great favor by benchrest insiders who tested it. It is also manufactured in Australia and Hodgdon introduced it as an IMR canister powder in 2010 (IMR-8208 XBR.) It is not the same as the original military surplus powder. Similar in appearance to Benchmark, it, too, is short cut, meters very well and burns cleanly. Both are a light gray/green in color.

Western Powders, under its Accurate Powder line, eventually approached General Dynamics in Ontario, Canada. This is the facility that manufactured DuPont powders in its later years before divesting itself of its smokeless powder division and manufactured all of IMR’s powders before Hodgdon’s purchase of the company. The facility also makes all of Accurate’s current extruded powders. It is from this facility that the original military powder was manufactured. Accurate’s goal was to actually duplicate the original powder – at the same facility on the same equipment. Remember Berger’s T32 offering? Accurate’s powder is LT-32. Not having any of the original military powder, I can’t speak to how close Accurate came to meeting its goal. I can say that LT-32 is faster burning than Benchmark which, in turn, is faster than IMR-8208 XBR. LT-32 is similar in appearance to both but is much darker in color, obviously employing a larger percentage of graphite in its makeup. Like the others, it meters very well and is very clean burning.

Prior to the release of Power Pro 1200-R, Alliant released another of its Power Pro line intended for a broader range of varmint cartridges, Power Pro Varmint. The powder works well in the 222 Remington but does not produce quite the velocity of the other powders and is perhaps best suited for cartridges with a larger case capacity.

Bullet selection was fairly easy with a dozen different choices on hand which were winnowed down to an even 10. The lightest, 32 grains, is from a relatively new entry into the bullet trade, Cutting Edge. The company’s products are lathe-turned on CNC equipment of either brass or copper. The product line is growing rapidly. For these tests I used the 32-grain PHD hollowpoint. A 40-grain flatbase hollowpoint is available but will not stabilize in the 222’s one-in-14-inch twist. It would be ideal in the faster-twist 223 Remington. Next was a Nosler 35-grain Lead Free Ballistic Tip with a fragmenting copper core. A pair of 40-grain bullets were run through their paces: a Berger flatbase HP and a Hornady V-MAX with moly coating. Continuing upward, a Nosler 45-grain solid base proved interesting. A cup-and-core bullet with an exposed lead tip and a moderately shaped boat-tail base, it lacked the high ballistic coefficient profile of most of the others but performed well nevertheless.

The 50-grain bullets included a svelte, flatbase hollowpoint from Berger, a Varminator hollowpoint from Barnes and another Hornady V-MAX with moly coating. The final selection was a Hornady 55-grain Spire Point. It was the only bullet with a cannelure and the only bullet that did not perform well in my rifle.

Tests began by first firing and chronographing Remington factory 50-grain loads. In Ken Waters’ “Pet Loads” on the 222 Remington in 1968, he chronographed factory 50-grain loads at 3,159 fps; in his 1977 revisit of the cartridge, factory 50-grain ammunition clocked 3,121 fps. My efforts sped over the screens at 3,146 fps, suggesting that Remington has maintained a consistent control over 222 Remington performance. Group sizes averaged right at .75 inch at 100 yards – not bad for a lightweight, rather used field gun.

Measuring the pressure ring in front of the extractor groove was next. New factory loads measured from .372 to .373 inch; after firing, the same cases measured .375 inch. Because of this and the original SAAMI specs, a maximum acceptable pressure ring measurement was established at .376 inch.

Quite a few cases were on hand, sorted, sized and trimmed to 1.690 inches and weighed. It turned out Federal, Winchester Super Speed and W-W Super cases all weighed approximately the same – within a few tenths – at 94.3 grains. R-P cases, on the other hand, averaged 88.9 grains. Almost all the loads in the accompanying table employed W-W Super cases. Those instances where R-P cases were used demonstrated no discernible difference in performance.

The first loading attempt was to duplicate the original 222 Remington efforts with IMR-4198 charge weights of 20.5 and 21.0 grains with 50-grain bullets. I repeated the tests with H-4198. In each case, the 50-grain Berger bullet with a cartridge overall length of 2.130 inches was used. I was more than pleased to find the 20.5/IMR-4198 load clocked 3,307 fps and produced a nifty .563-inch group at 100 yards. The 21.0-grain load was even more impressive at 3,384 fps and a .438-inch, three-shot group. H-4198 wasn’t far behind with its 20.5-grain load recording 3,240 fps while registering a .625-inch group. The 21.0-grain load came in at 3,374 fps and an .688-inch spread. It is easy to see why “4198” was, and is, so popular.

Case stretching was explored at some length. There were some cases approaching the 1.700-inch maximum after the third reload. This can be slowed by avoiding the maximum powder charge in most loads. Fortunately, this can be backed up by the fact that frequently the tightest group was obtained with the less-than-maximum load in each powder listing.

In reviewing results with the new powders, there were no disappointments. Among the extruded, single-base powders, I was very impressed with Accurate LT-32 and IMR-8208 XBR. Among the double-base ball powders, Alliant’s Power Pro 1200-R gave very good results. Hodgdon CFE 223 deserves further study for its reduction in metal fouling qualities alone. Fortunately, the powder held its own in accuracy as well. I would suggest that the starting loads for each powder be at least 2.0 grains below the listed maximum and increased only if warranted. Do not exceed listed maximums. Fans of the original 4198 have nothing to hang their heads over, but some of these newer powders can increase velocity a bit without loss of accuracy.