Oregunsmithing's 24 York

An Ultra-Efficient Varmint Options

feature By: Patrick Meitin | October, 23

Visiting Wayne in Pendleton recently, dropping off a couple rifles to be threaded to accept suppressors, he asked if I had any interest in shooting a 24 York rifle he had recently built for varmint shooting – specifically to take on his annual prairie dog forays to Wyoming. I am always glad to shoot one of York’s Oregunsmithing creations and this project would also help expand choices of viable loads for his varmint-shooting passions.

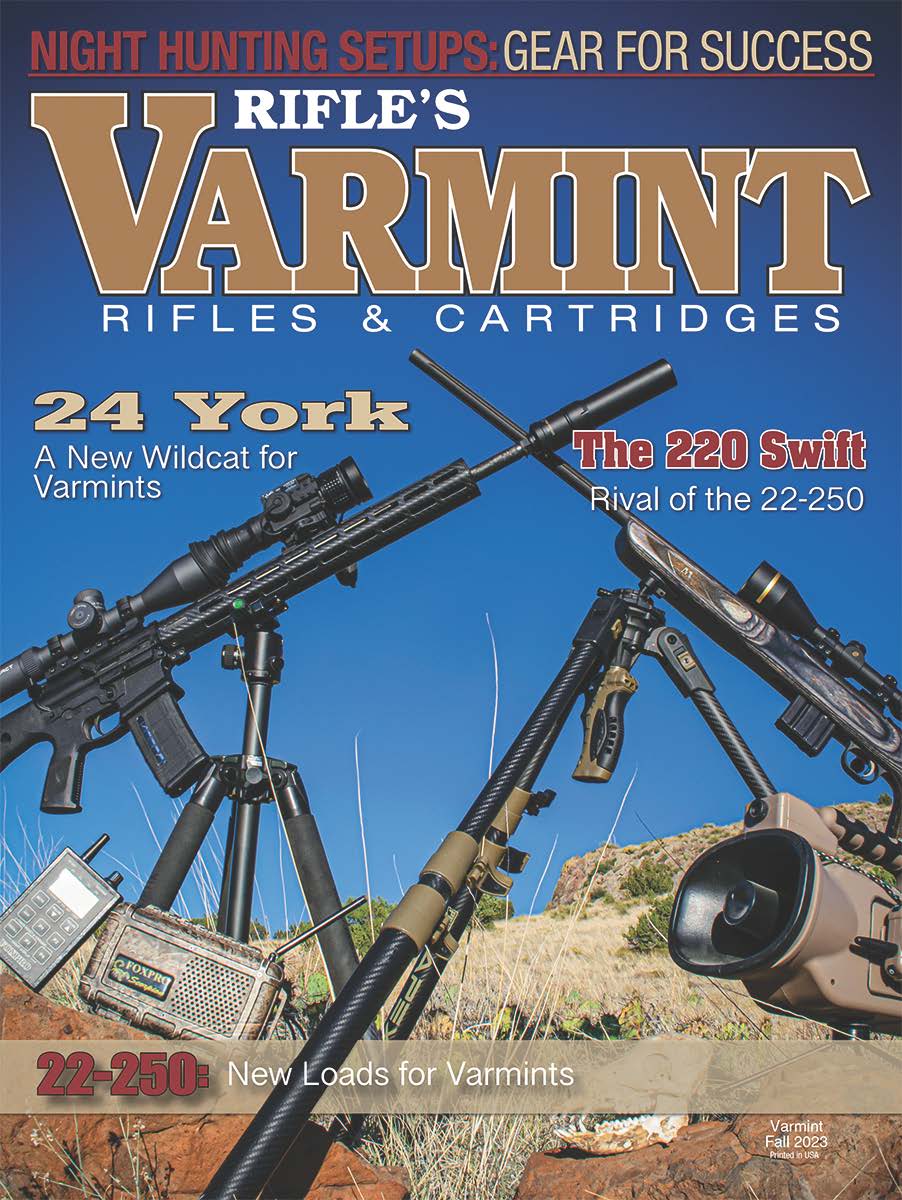

The barreled action was dropped into one of York’s hand-laid Pendleton Composite Stocks (PCS) T11 models, a beefy tactical-style handle including a carbon makeup, vertical grip, and holding an adjustable comb and buttpad to adapt length of pull to specific shooters. A Coyote finish with black and tan spider webbing completed the stock’s finish. Wayne added some lead to the forend during the build to make it more stable on a rest. Howa’s polymer trigger guard/magazine-well assembly was retained with the rifle feeding from a detachable Howa polymer magazine. The action, barrel and bottom metal were given a Coyote Tan CERAKOTE finish.

The 24 York case includes an overall length of 1.70 inches, base to shoulder length of 1.398 inches, and the neck is .259 inch. It included a 30-degree shoulder, case taper taken from .420 inch at the base to .399 inch at the shoulders. By comparison, the parent 6.8 Remington SPC case included an overall length of 1.686 inches, base-to-shoulder length of 1.301 inches, and the neck is .272-inch long. The SPC shoulder is set at 23 degrees and the body included more taper for smooth AR-15 feeding. The 224 Valkyrie makes another apt comparison, which also uses the SPC as a parent case. It included an overall length of 1.600 inches, base-to-shoulder length of 1.203 inches, a .269-inch neck length, and 30-degree shoulder. The new RCC brass used for loading the 24 York included small rifle primer pockets. The round would also make an excellent fast-twist option, shooting long-for-caliber bullets in the 105-grain class, providing a mild-mannered, pleasant-shooting long-range target combination.

As it is a proprietary cartridge, one of the stumbling blocks to owning and shooting a 24 York was once creating brass, and securing proper dies. To help boost interest in his York cartridges, Wayne partnered with Robertson Cartridge Company, aka RCC (recently purchased by Custom Cartridge & Projectile in Fort Meyers, Florida) to supply ready-made cases, and CH-4D to produce full-length die sets. RCC cases include high-strength C272 brass alloy, hammer-forged into a tight molecular grain structure with high tensile strength and 15 percent elasticity. Cases are then machined on CNC lathes and mills to tighten weight and volume tolerances and include .001-inch concentricity. York is also talking to Pendleton Ammunition, hoping to strike a deal to provide loaded factory rounds.

Cases for the 24 (and 25) York can also be made by running readily available 6.8 SPC brass through a Redding bushing die to neck down to the desired caliber, charging with a moderate load, and then fireforming in a York-chambered rifle. The trim-to length is 1.40 inches, though York said fireformed brass usually emerges from the chamber at the proper length. Another stumbling block to shooting the 24 York is lack of load data. This was made easier with the introduction of the 6mm ARC, as it includes identical case capacity as the 24 York. Ten once-fired Hornady 6mm ARC cases with spent primer in place held an average of 32 grains of water when filled to the brim, while 24 York cases held 31.9 grains of water. The 224 Valkyrie (Federal case) holds 30.3 grains of water, and the 6mm PPC 34.1 grains. Data for the ARC works well for the 24 York, though it should be approached conservatively until you gain a better feel, as the two rounds include different chamber dynamics. Data for some of the newest powders (Winchester StaBALL Match and Alliant Reloder TS 15.5) included in this test was carefully extrapolated from printed 224 Valkyrie recipes.

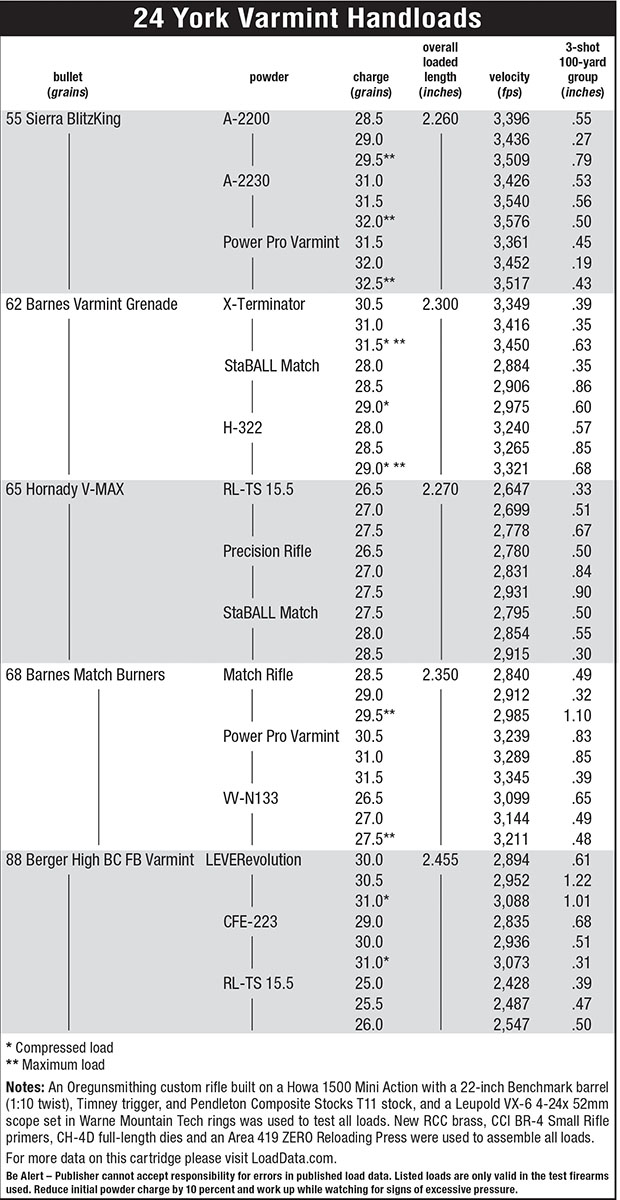

All bullets tested were varmint numbers selected to serve Wayne’s intended goals. On the light end was Sierra’s 55-grain BlitzKing, a polymer-tipped, boat-tail design giving up a .225 G1 ballistic coefficient (BC) and providing explosive terminal performance. Barnes’ 62-grain Varmint Grenade was up next, a flatbase, nontoxic bullet designed for explosive impacts on small varmints. This one included a .199 G1 BC. Hornady’s 65-grain V-MAX is the consummate varmint bullet, a red polymer tip and boat-tail provided a .280 G1 BC and providing dismantling impacts. Barnes’ 68-grain Match Burners is a flatbase target bullet, but included a thin jacket and hollowpoint that expand aggressively, while providing a .267 G1 BC. Finally, Berger’s 88-grain High BC FB (Flat Base) Varmint provided both a high .380 G1 BC and excellent expansion on smaller targets. All turned in excellent groups.

I was afraid the Sierra 55-grain might prove too squatty for top accuracy from this rifle, but I was proven wrong when shooting began. In fact, the bullet turned in the two smallest groups of any bullet tested, while also producing stellar velocity. Accurate A-2200 and A-2230, plus Alliant Power Pro Varmint, were paired with the BlitzKing, and all hit top velocities in excess of 3,500 fps. A-2230 proved most consistent across the board, all groups hovering around a half-inch at velocities from 3,426 to 3,576 fps using 31, 31.5 and 32 grains of powder. That was also the fastest velocity with this bullet. A-2200 produced a .27-inch group at 3,436 fps using 29 grains of powder, while Power Pro Varmint produced a .19-inch group at 3,452 fps using 32 grains of powder. The other two groups also broke a half-inch.

The Hornady 65-grain served as the true guinea pig, stoked with new Alliant Reloder TS 15.5 and newer Winchester StaBALL Match, plus Shooters World Precision Rifle. All provided somewhat lackluster velocity, telling me these powders were perhaps a touch slow burning for this cartridge, though accuracy was certainly exceptional. Reloder TS 15.5 turned in .33- and .51-inch groups at just 2,647 and 2,699 fps, using 26.5 and 27 grains of powder. Group size increased with 29 grains of powder, about as much as you can get in the case without severely compressing each load. Precision Rifle also shot its best group with the lightest load, printing .50 inch at a faster 2,780 fps. This powder could be pushed a bit beyond the 27.5-grain “maximum” used. StaBALL Match proved remarkably consistent, 27.5-, 28- and 28.5-grain charges produced .50-, .55- and .30-inch groups at 2,795 to 2,915 fps. That .30-inch group was the tightest shot with this bullet.

LEVERevolution, which is a top-three choice in the 6mm ARC, proved dismal from the 24 York while shooting the Berger 88-grain bullet. None of the groups broke half an inch, with the test’s 1.22-inch worst included. Luckily, CFE 223 and Reloder TS 15.5 improved things immediately.

Reloder TS 15.5 lacked the pace again, with velocities from 2,428 to 2,547 fps all it managed with this bullet using 25 to 26 grains of powder, but with impressive .39-, .47- and .50-inch groups. No pressure signs resulted from listed loads, so they could be carefully pushed a little faster. CFE 223 proved the star with the heavier bullet, .51- and .31-inch groups (the best from this bullet) emerged from 30 and a compressed load of 31 grains of powder. Velocities were 2,936 fps with 30 grains, and 3,073 fps with 31 grains of powder.

York has obviously assembled a winner with both his 24 York cartridge and this rifle. The heavy rifle will make an ideal choice for the bench-based prairie dog hunting it was built for, the 6mm bullets providing both the zap and wind-bucking abilities needed on the invariably breezy conditions found on the plains of Wyoming.