The Saga of the 219 Donaldson Wasp

History, Development and Current Status

feature By: Stan Trzoniec | April, 23

This was not the first chuck we had seen that day, as some of the others were too far out, or the terrain behind them was not good for shooting to act as a backstop. Overall, the day was a perfect summer’s day, temperatures in the low 80s with just a bit of a breeze to take in the aroma of the freshly cut hay laying in the field before us.

The rifle I had with me had been a combination of efforts between rifle and cartridge that I had wanted to see happen for a long time and finally did a few years earlier. Granted, the Ruger No. 1 is not a big thing, but considering it was open to rechambering to many varmint cartridges, it was my pick to have it enter into a second life as the 219 Donaldson Wasp, which turned out to be the easier part of this journey.

The model number of the Ruger is the 1-B, a standard variation chambered for the 218 Bee with a 26-inch barrel and longer forearm. It was rechambered by Bullberry Barrel Works of Hurricane, Utah, but recently, Fred Smith had retired and handed the reins over to his right-hand man, so the business will continue if you are serious about working with the Donaldson cartridge. Along with a Bausch & Lomb 6-24x power scope, I was eager to get the ball rolling.

I found that after some work by Donaldson himself, at that time, the Wasp was considered by many to be nothing more than a blown out Zipper (ill informed). Velocities are similar, maybe so, but keep in mind the Zipper had limited availability and use – only being chambered in lever-action guns – and here is where the Wasp pulled ahead in popularity with its use in bolt-action rifles.

By now, he had accumulated more than 52 years as a rifleman and experimenter who was always on the lookout for a better varmint cartridge without going toward “improving” the same, but something that would be worthy of long-run applications with a smaller case. He was working with the 22 Niedner that lit the spark to continue down the line – away from larger cases that simply held more powder leading to more throat erosion and possible higher pressures – not very suitable for spending a day in the field with multiple shots and more recoil.

Next up, was the 25 Remington, a rimless case with a larger interior volume holding about 8 more grains of powder, necked-down to his pet .22-caliber round and fireformed in the rifle. Shooting it more, he liked it less, as it never was up to the velocity he had expected with unburned powder still left in the case after firing. A shorter,

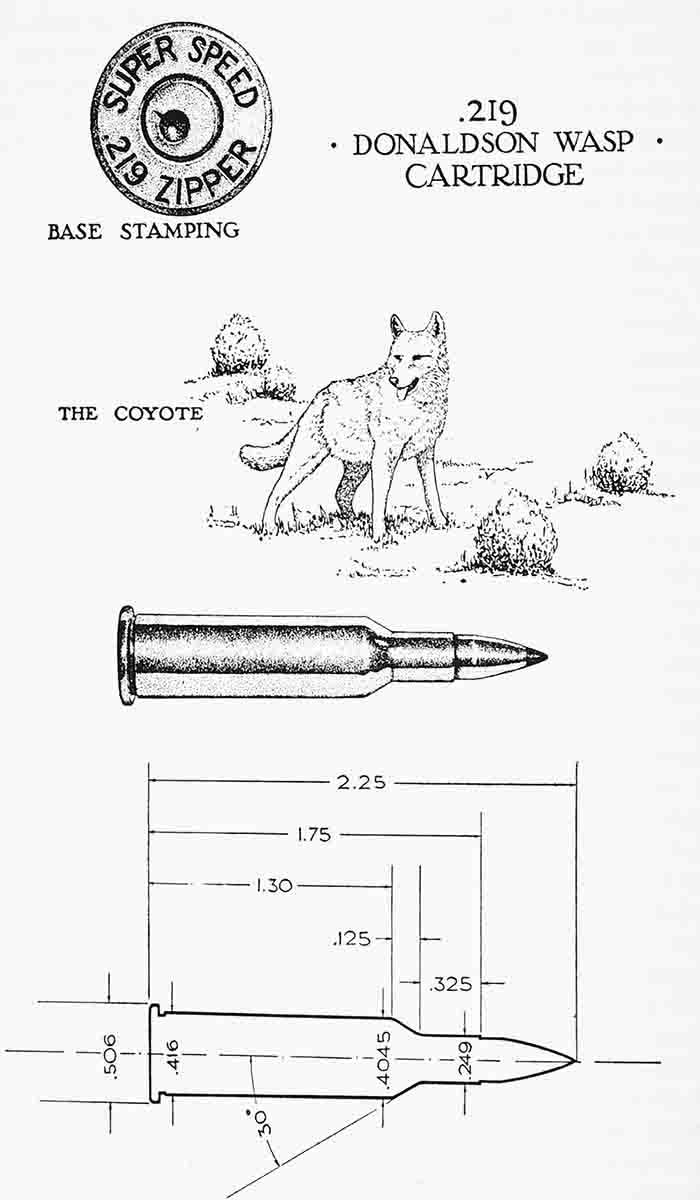

Apparently, it was and came in many forms. For one, it was left in its original shape, the shoulder was made a little more abrupt allowing it to be formed right in his Winchester 30-30 bolt-action rifle with just a barrel change with a 1:14 twist and without any case-forming dies, much like the improved cases of today. The Zipper was a case of hefty proportions and employing the same receiver delimited the need for a change in the bolt, bolt head or extractor.

Still another important fact holding true today and emphasized in Twenty-Two Caliber Varmint Rifles by Charles Landis (Wolfe Publishing, 1991). In his writings, Landis goes on to say and I’ll quote, “the .219 Wasp design was worked out by Donaldson with the idea of having both bullet weight and the powder weight so balanced that a case full of powder could be used without exceeding safe pressures, or without having it fail to reach adequate burning pressures.” Donaldson was finally on the way with his pet project – the 219 Donaldson Wasp – still hard to beat and still within a class to itself. Looking back, the demise of the 219 Zipper and brass did not help the situation, but today, there are ways of getting around this in bringing the Wasp up to speed.

Assuming you have the rifle, as you will need it for the final fire-forming, the next step is getting the 30-30 into the 219 case – a number established by the Wasp starting out from this case. Order the RCBS case forming set under the number 358024, which is a three-die set including a forming/trim die. Additionally, you will need the traditional full-length set under the number 56003 and the number 2 shellholder. Count off about 20-25 cases for your first time through the dies assembly line style.

The first die requires some effort on your part as it pushes the shoulder back roughly .635 inch, or about a third of the 30-30 case. When working with this first step, I found it’s best to roll the case softly on the lube pad being careful to keep the lubricant off the shoulder area. This prevents case dents from forming and although they can be blown out during the fireforming, they can weaken the case for future reloads. Now, take a bit of lube between your finger and thumb placing just a small amount on the neck to ease it into the die. At this point, the Winchester case has not grown in size but retains its original 2.039-inch length; with the outside neck diameter slightly reduced to .326 inch.

The last die is the trim die and will reduce the outside dimension to .255 inch, an inside measurement of .228 inch. Now, trim the cases with a hobby hack or razor saw right down to the die body finishing off with a file, which should finish up to 1.765 inches. Finally, set your case trimmer to 1.745 inches, which is the perfect length for the Wasp that will max out to no more than 1.750 inches after some firings finishing up with a trip through the full-length sizing die just to square things up including the neck.

One thing I want to make clear, and I believe I went over this before, is that the dimensions in the Hornady 7th and 8th loading manual are in error for the traditional cartridge as Donaldson designed it. These dimensions are for the longer, modern version of the cartridge “as a result of measurements taken from the front of the rim instead of the rear” that amount to a case length of 1.813 inches (1.750 plus .063-inch rim thickness) an error that has been noted on other wildcats.

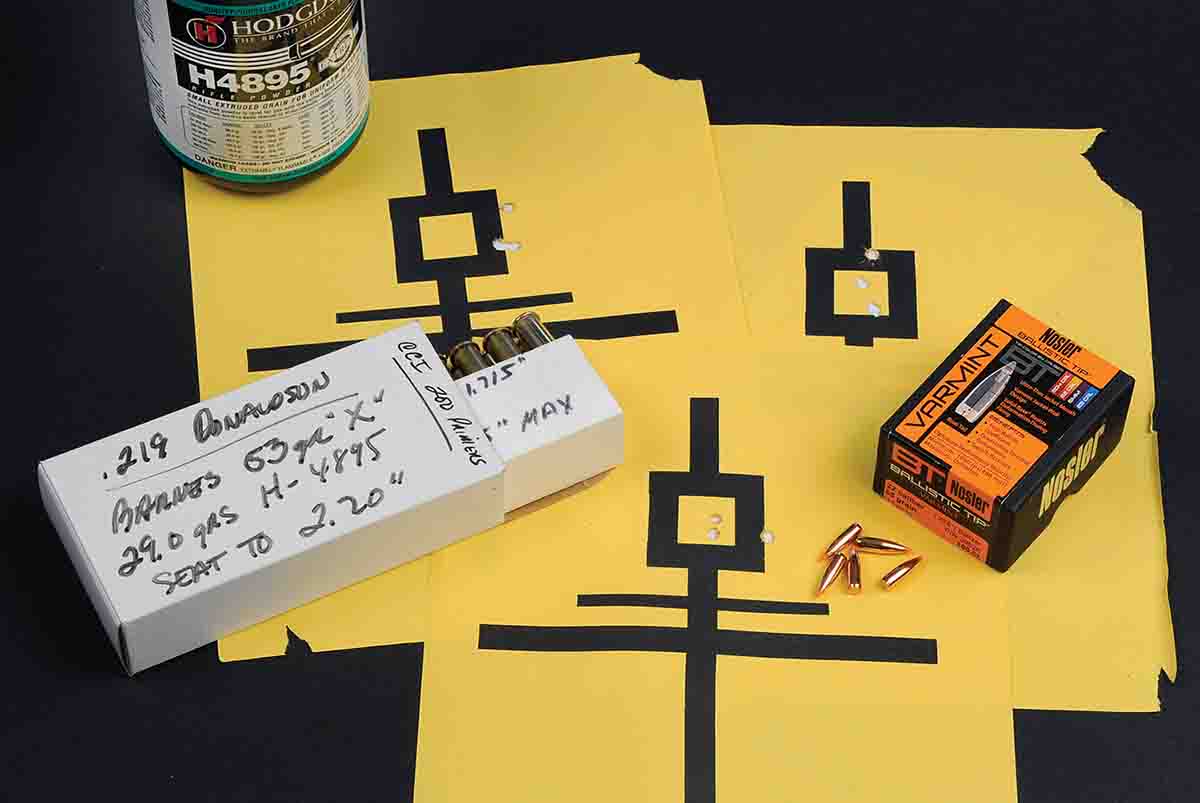

When it came to powders, the Wasp is perfectly at home within the medium to slow category on the burning rate scale. From H-4198 to H-380 and everything in between, the cartridge just happily purred along with more than decent velocities and great accuracy.

Bullets, of course, are always a matter of personal choice depending on the game hunted, distance and the preference of the rifle to produce the best groups. Like some of the factory ammunition on the market today, bullets made by Sierra, Speer, Berger, Hornady or Barnes seem to have no end to what they can produce downrange. By some serious handloading, I found that with the Wasp’s case design, I had little or no problems in setting the tone for some tight groups and velocities that would get me over the mark for the modest distances we have here in New England between the older stonewalls. During “chuck” season, the Ruger rifle proved its mettle and going afield with a single-shot rifle chambered for an extraordinary vintage cartridge just added to the fun of the hunt.

No doubt, you have sensed my favoritism towards the 219 Donaldson Wasp. Mention has always been made as to how the 22/250 Remington could be, might be or should be a better alternative, but when I dig into the cartridge like this, chamber a rifle for it and work the round into a wildcat I can fire, it wins hands down – all the time.

Harvey led a full life doing what he wanted to do. He gave birth to a number of productive cartridges, was deep into handloading and ballistics and his book titled Yours Truly is a classic and something every rifle enthusiast should read. Donaldson died on November 6, 1972.

Thanks Harvey. You did good.

Ode to “Chuck Huntin”

He’s prolific, he’s terrific

and with any kind of luck,

I’ll be three score ten and plenty

when I shoot my last woodchuck….

– D.M. Moroughan