17/23 SMc Long-Neck

A Wildcat in Its Early Stages

feature By: M.L. McPherson | April, 16

Searching for a .17-caliber cartridge that provides serious performance, and an accurate scoped rifle weighing 10 pounds or less that would allow taking advantage of what the cartridge could do, no commercially offered rifle filled the bill, so the task of building one began. An “improved” 17 Remington Fireball, the 17/23 SMC is an almost ideal, minimalist varminting cartridge. Making 17/23 SMC cases is easy; just fire 17 Fireball ammunition in the 17/23 SMC chamber. The short case neck compromises barrel life in a varmint rifle, however, and all the

barrel life that could be had was wanted, so 223 Remington cases were converted to make a long-necked version, resulting in the 17/23 SMC Long-Neck. This cartridge, it is my belief, minimizes the mass of unburned propellant accelerating into the bore, reducing barrel heating and felt recoil while maximizing barrel life. With 13 percent less powder capacity, the 17/23 SMC Long-Neck duplicates 17 Remington performance.

The Rifle

The Savage dual-port Target action is a favorite receiver. It is particularly useful for a varmint rifle, and it has a very good, adjustable trigger. To reduce weight, the receiver was modified (metal removed) to make it lighter, and the lightest Pacific Tool & Gauge bolt body was used, along with a Delrin bolt-handle knob. Even the trigger guard was whittled on. The addition of a third action screw is an important target action feature. (After seeing a Savage prototype, I started modifying my Model 12s to include a third action screw.)

Hollowing out a laminated Savage F-Class stock reduced its weight by 50 percent while keeping roughly 90 percent of its original rigidity, but this stock did not work well when shooting off a Dog Gone Good bag. So I hollowed out and modified a Model 12 stock to fit the target action. The rifle components weighed 10.25 pounds. (A McMillan HBR Edge stock has been ordered. It is expected to weigh .75 pound less, bringing the finished rifle weight to roughly 9.5 pounds.)

When considering fouling and accuracy, the smaller the bore, the more critical bore quality can be, so a top-quality, Pac-Nor barrel with a one-in-9-inch twist was chosen. Because I know what actually heats a barrel (elastic deformation, as the pressure peaks and drops off), I also know the smaller the barrel diameter, the more quickly it will heat up. This results in a compromise between barrel heating and weight. Settled on was the same muzzle diameter that Savage uses in its varmint rifles (0.8 inch). Barrel fluting reduces weight without compromising accuracy. A fluted barrel may heat up more quickly than an unfluted barrel, but it will also cool more quickly.

No such thing as too-little recoil exists, so a Lightweight Air Working (LAW) muzzle brake was installed by Pac-Nor. The LAW’s rearward-venting ports minimize recoil, allowing me to see hits and misses better without increasing muzzle blast enough to notice, and it reduces downrange noise (less apt to disturb vermin). With 25-grain bullets, I hardly can tell that the rifle moves upon firing; with 20-grain bullets, the rifle feels as though there is no rearward recoil.

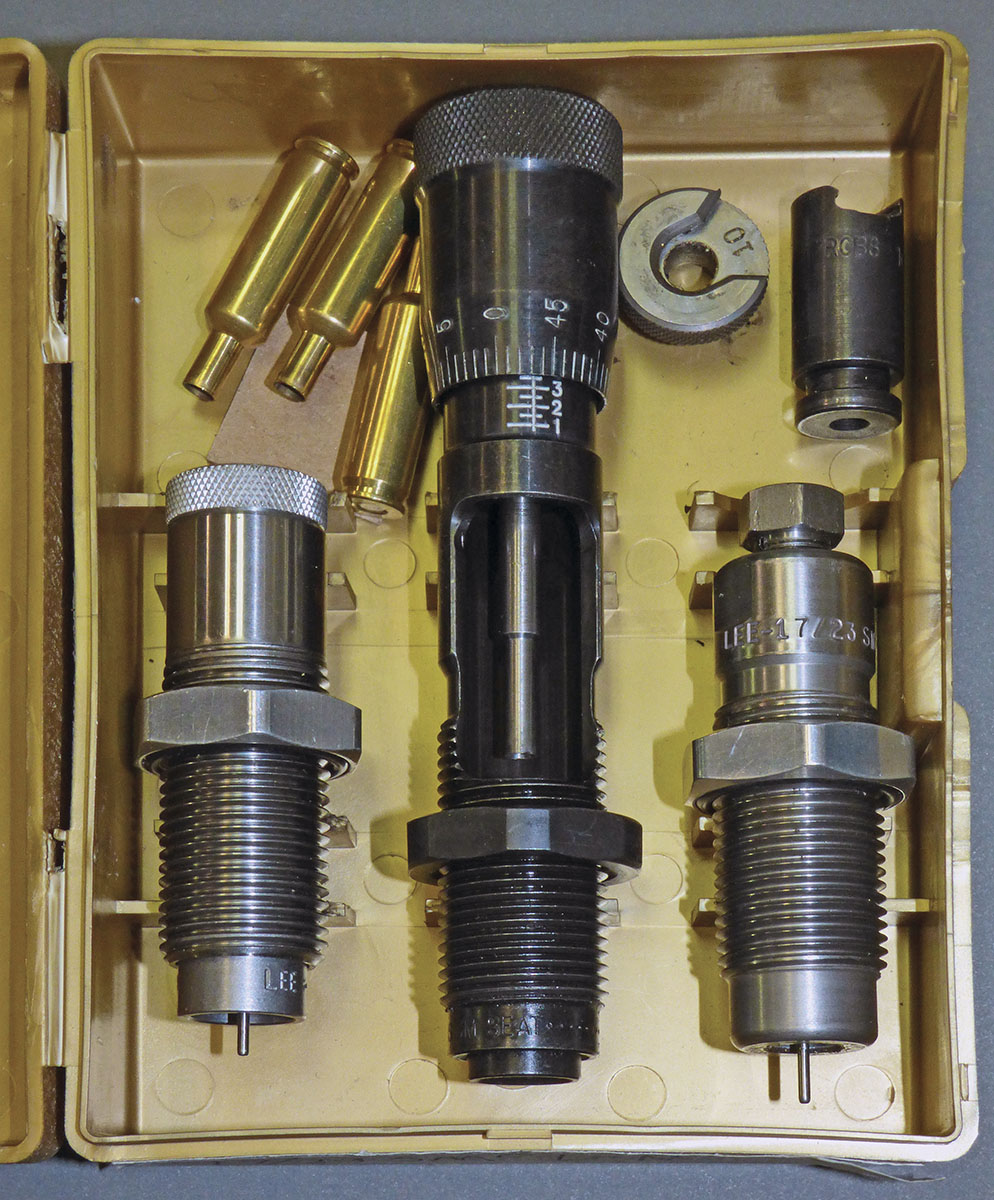

The reamer for barrel chambering was made by Pacific Tool & Gauge. For a varminting rifle, I prefer the chamber neck to closely fit the cartridge neck, in both length and diameter; a short throat and a standard benchrest leade angle are both preferred. Headspace was set up to minimize case stretching, because I would rather shoot than trim cases. With the SMC cartridge’s shoulder design and ideal resizing, cases will not stretch enough to matter. For initial range testing, a Nightforce ATAC-R 5-25x scope was installed on the rifle. For varminting, a Leupold VX-6 4-24x, which has every feature

preferred, including a Long Range Varmint reticle, will be installed.

Load Work-Up

Conversion of 223 Remington cases to 17/23 SMC Long-Neck was arduous and included the following steps: drive the shoulder back, size the neck down, trim to length, anneal, outside neck turn and fireform. Nothing to it, except that I wanted 2,000 finished cases prepared to last through several days of varminting and wanted to use top-quality brass. Unfortunately, when it came time to make the cases, Norma brass was not available, and only 1,000 Lapua cases could be found, so about 1,200 Lake City (LC) once-fired military cases were also used. The end result was 2,167 cases, enough ammunition to last through several days of serious varminting. With proper maintenance (chiefly, correct resizing and occasional neck annealing), this brass is expected to outlast many barrels.

The Lapua cases are about four grains heavier than the LC cases. With the same charge in each, the Lapua cases generate slightly higher pressure and about 38 fps additional velocity. To keep pressure and velocity similar, about .25 grain less propellant is used in the Lapua cases. For initial testing, Federal 205M primers were used first, because they usually work well, and I had a good supply. H-322 and IMR-8208 XBR powders were used, because they are clean burning and, in my experience, are minimally sensitive to ambient temperature. Also tested was IMR-4166, because it offers high performance and copper fouling elimination. Three spherical powders were also used: X-Terminator, LEVERevolution and CFE 223. Although the spherical powders showed promise, and 8208 XBR gave higher velocity than H-322, I settled on H-322, because it meters more easily into .17-caliber cases. IMR-4166 was too slow to give expected velocities, and case charging was tedious.

I prefer tipped bullets properly moly-coated, because in my experience with varmint rifles, barrels tend to last longer when moly-plated bullets are used. Considered for this project were Nosler 20-grain Varmageddon and Hornady 20- and 25-grain V-MAX bullets. In looking at external ballistics for all three, with maximum feasible loads the 25-grain V-MAX has an edge over the 20-grain options.

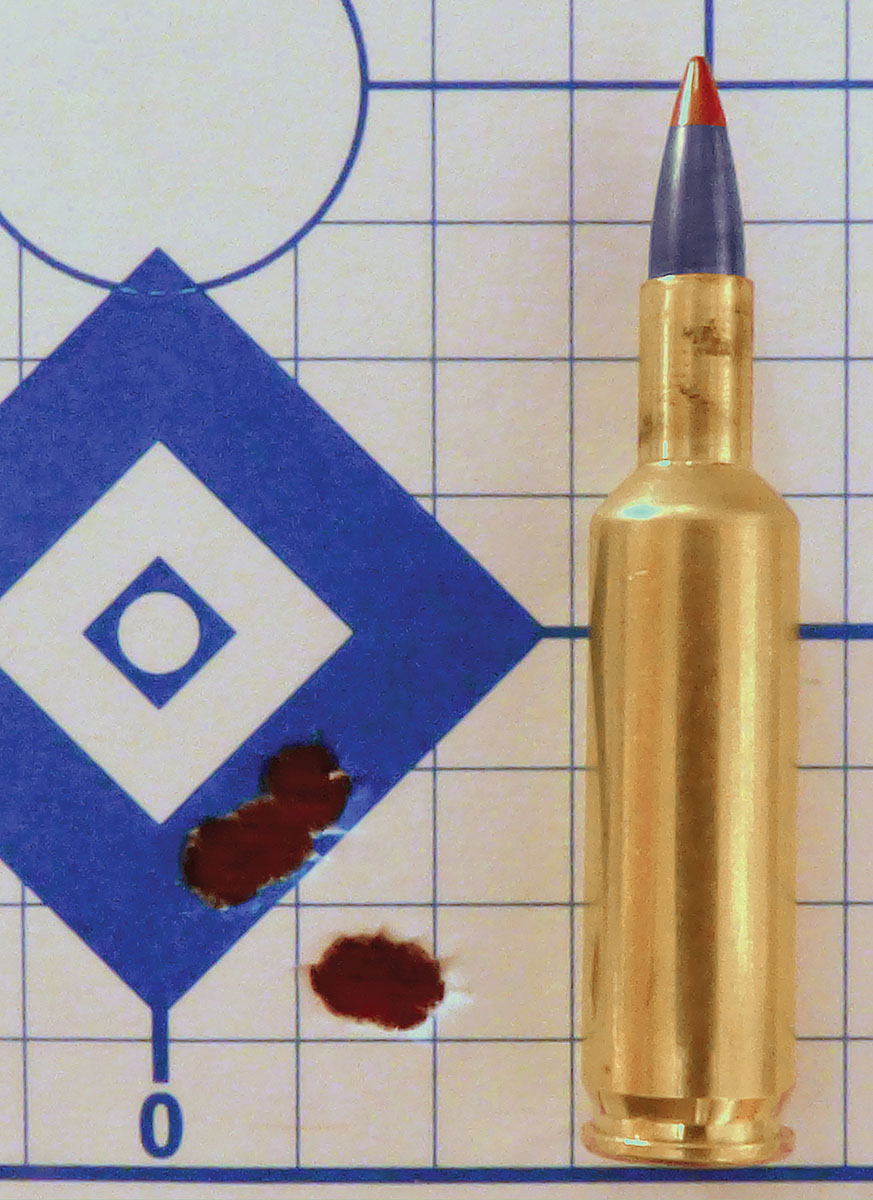

In a primer comparison test with the Hornady 25-grain V-MAX and H-322 powder, Remington 71⁄2 primers yielded only a 36 fps extreme velocity spread for 10 shots, with two, five-shot, 100-yard groups measuring under 0.4 inch. Federal 205M primers were second best while WSR, CCI 400 and Wolf primers each produced unacceptable velocity swings and fliers.

Next came determining a reasonable maximum load. For this I do not like to rely on measuring case heads as a determinant of “safe” pressure. I don’t trust the method, because my original 270 Winchester elk load, developed in 1973, showed no case-head deformation and extracted freely from my Remington pump, which has no extraction camming ability to discard spent cases. I just knew it was safe, then I tested it – pressure exceeded proof load pressure.

With an understanding of internal ballistics, I prefer to verify wildcat loads using QuickLOAD software. The QuickLOAD prediction is compared with what is known from experience. If the two jive reasonably well, I know the pressure predicted by QuickLOAD for any given load combination and muzzle velocity is reasonably close to actual chamber pressure, despite any small variation in actual charge versus a QuickLOAD predicted charge. Still, a handloader is wise to study case heads for any signs of pressure.

QuickLOAD suggests that the top loads reported here generate pressures similar to maximum 17 Remington loads, or about 63,000 psi, according to current SAAMI standards. There was no evidence of excessive pressure on the handloads. Case heads did not deform, primers did not excessively flatten and bolt opening and extraction were normal. One batch of cases was put through eight neck-sizing, loading and firing cycles using “maximum” loads, and all continued to freely chamber, and primer pockets remained tight.

Component production lots, loading practices and loading tools matter. A handloader should never attempt to duplicate any load without careful load development, while observing pressure markers and velocity. While some barrels do give unusually high velocity, if you are getting higher velocity from a barrel of the same length, most likely your loads are generating higher pressure. Regarding barrel length for this cartridge, typical per-inch velocity difference will be roughly 33 fps with 25-grain bullets or 37 fps with 20-grain bullets.

During the first range trip, it was 38 degrees outside. Half-grain incremental charges of H-322 with Federal 205M primers along with Hornady 25-grain V-MAX bullets showed 3,595 fps (17.5-grain charge) and 3,795 fps (18.5-grain charge) with good velocity uniformity and accuracy. Various charges of IMR-4166 were also tried to see if the powder would work, but velocities were slower than expected.

During the second range trip, it was 78 degrees. Ballistics and accuracy were compared with Hornady 20-grain V-MAX bullets using various seating depths and 20.3 grains of H-322 in the more capacious LC cases and 20.5 grains of 8208 XBR in Lapua cases. Bullet-to-rifling jump was tested in .003-inch increments, from .008 to .020 inch. Ballistic uniformity was generally best with a bullet-to-rifling jump near .010 inch. Both velocity and accuracy generally increased with progressively less bullet jump. The most accurate H-322 load generated 4,167 fps. The most accurate IMR-8208 XBR load generated 4,239 fps, probably due to slightly higher pressure.

In continued evaluation, 10 or more shots of various test loads were chronographed to measure velocity and consistency. Alternately, a friend or I fired five-shot, 100-yard groups. Excepting occasional velocity and accuracy fliers that resulted from a problem with some of the cases, which was unrecognized until considerable testing had been done, the results were quite pleasing. Once the case problem was solved and only good cases were used thereafter, both accuracy and extreme velocity spreads improved.

Recently, an otherwise similar one-in-8-inch twist Pac-Nor barrel with polygonal rifling was ordered. I will chamber that and have it on a shelf, ready to go. I suspect that the faster twist might improve accuracy with the Hornady 25-grain V-MAX. The faster spin is also expected to improve terminal performance.