257 Roberts

Varmint Loads for a Classic 25

feature By: R.H. VanDenburg, Jr. | April, 16

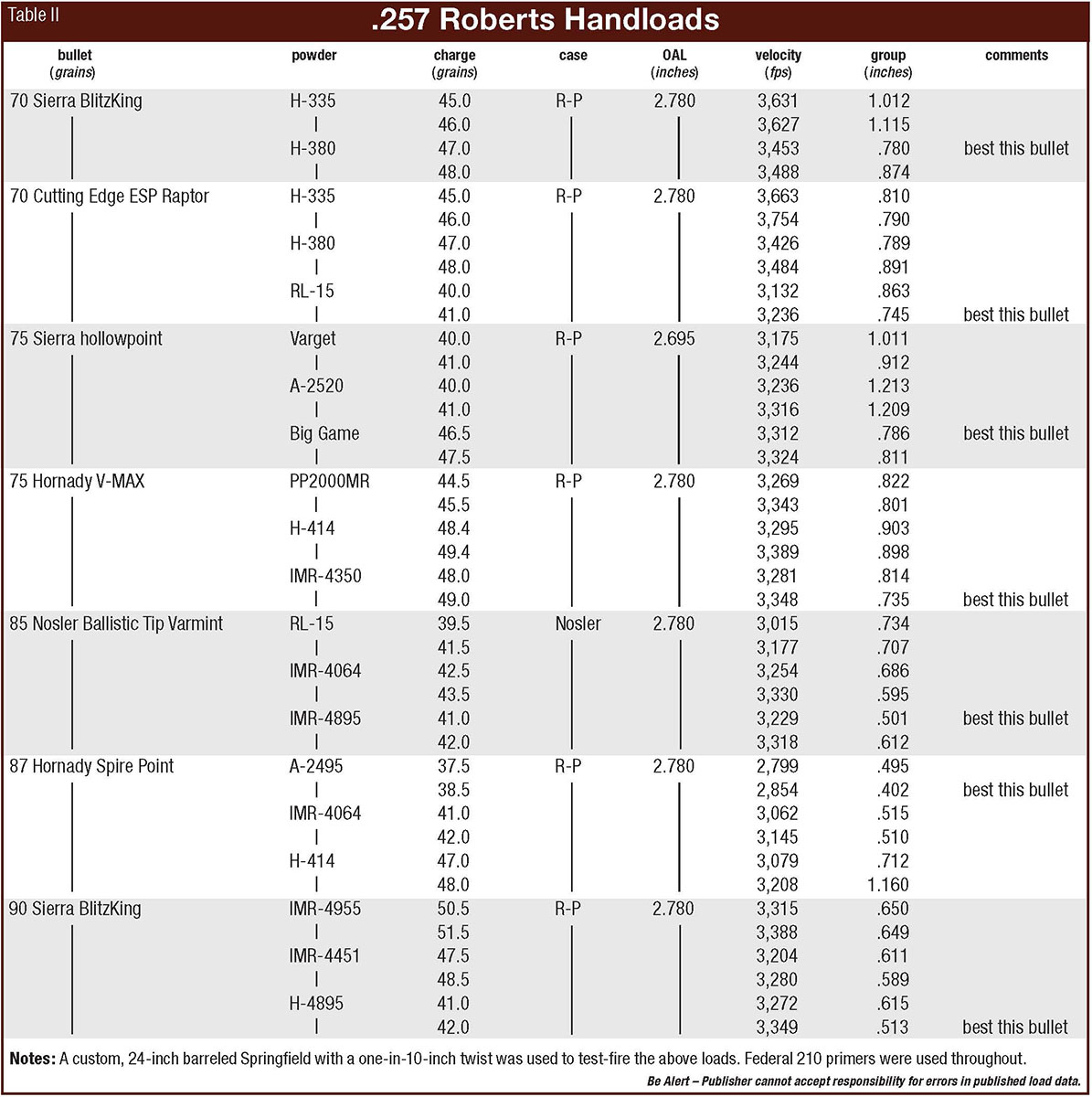

As noted then, Ned H. Roberts and friend and co-experimenter F.J. Sage spent 17 years, from 1910 to 1927, exploring the potential of the .25-caliber bore. After much testing, they concluded the ideal case would be the 7mm Mauser. Roberts at first shortened the case, but further experimenting by others led to the use of the case at its full length. Likewise the shoulder angle fluctuated as Roberts, the Niedner Rifle Company, Griffin & Howe and, finally, Remington experimented with it. When the Remington Arms Company legitimized the cartridge in 1934 in its Model 30-S rifle, the cartridge was defined as having a shoulder angle of 20 degrees, 45 minutes. The SAAMI overall cartridge length was originally 2.775 inches, and may still be, but most recent reloading manuals give the figure as 2.780 inches. Either correlates to a short-action rifle, the magazines of which will accept cartridges of up to 2.780 inches in length.

Roberts’s goal was to create a cartridge capable of target accuracy. His oft-published ideal was one-inch, 10-shot groups at 100 yards; 2-inch, 10-shot groups at 200 yards; and 3-inch, 10-shot groups at 300 yards. Twist rate was of paramount concern, and he experimented with many, ultimately concluding that bullets of 87 to 100 grains would benefit most from a one-in-12-, 13- or 14-inch twist rate. For heavier 115- to 120-grain bullets a one-in-8- or 9-inch rate would be best. As Roberts was a confirmed varmint hunter, he favored the former. That almost all 257 factory barrels made today have a one-in-10-inch twist rate is simply a compromise. That said, one-in-10-inch twist barrels work reasonably well with varmint weight bullets and hold their own with heavier bullets, especially when driven at maximum velocities.

My own rifle is a long Springfield action with a custom one-in-10-inch twist barrel throated out for 115- to 120-grain bullets. Potential overall cartridge length exceeds 3 inches. I wanted a plains rifle, pure and simple, and that is what I got. The deer occupying my freezer fell to it last fall. For all that, the rifle gives up little in the way of accuracy with most modern varmint bullets, as they tend to be much longer, often with polymer tips, than earlier style bullets and can be seated out a reasonable amount to minimize bullet travel before engaging the lands.

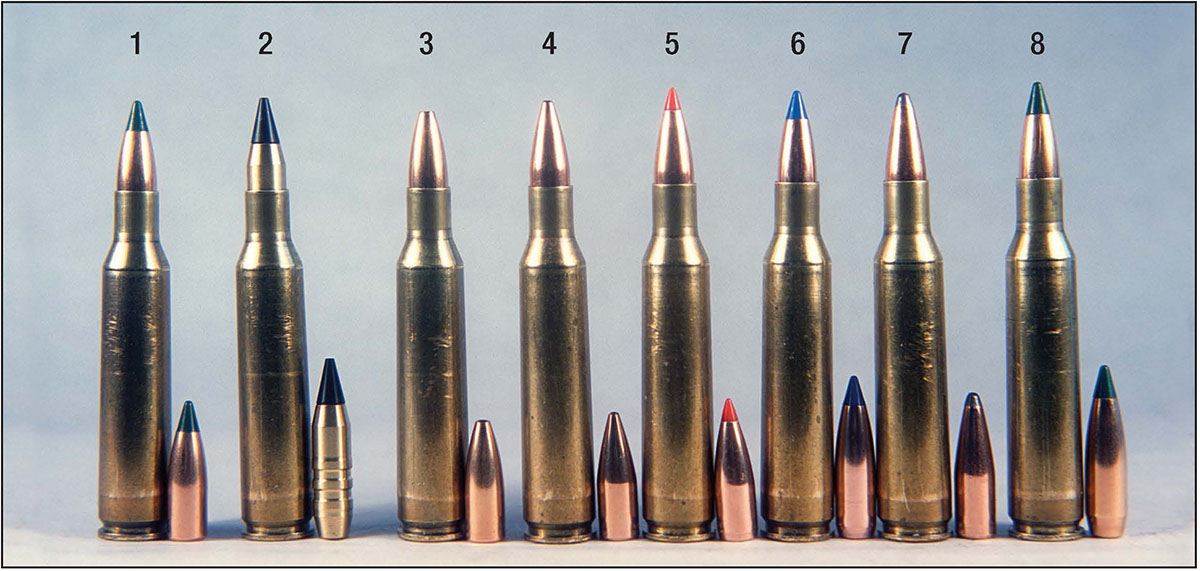

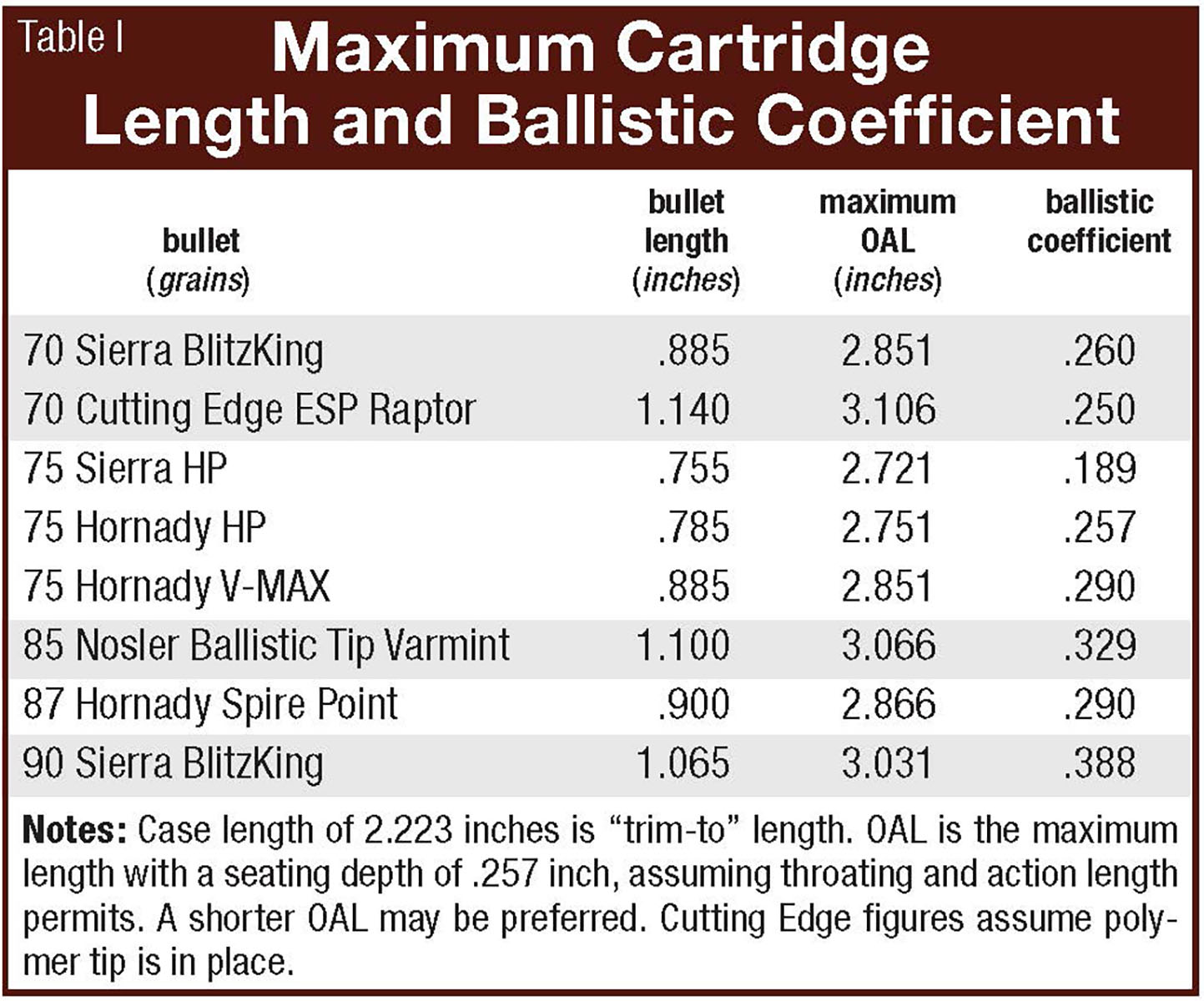

Let’s begin with a review of the bullets. Ignored as unsuitable were the 60-grain bullets originally developed for the 25-20 Winchester. The relatively low ballistic coefficients would preclude any reasonable accuracy at longer ranges. The first I worked with was the Sierra 70-grain BlitzKing. It is a flatbase, cup-and-core bullet with a polymer tip. The ballistic coefficient is listed as .260. It seldom disappointed with at least one powder producing sub-one-inch groups.

The Cutting Edge 70-grain ESP Raptor was easily the most interesting bullet. Made of solid brass and turned on a CNC machine, the bullet has a boat-tail and two relief grooves creating three driving bands. The shank diameter in front of the first driving band is .250 inch. What makes the bullet so interesting is that it is intended to be used with a polymer tip, giving a ballistic coefficient of .250, but the tips are not installed. Instead the bullets come separate with a large hollowpoint. The tips must be installed by the reloader. I used them and assembled them with the aid of a small vise. (The bullets may be used with the polymer tip in place, without the tip or even reversed and used as a solid.)

The first of the 75-grain bullets was the Sierra hollowpoint. Flatbase, cup-and-core, its ballistic coefficient is but .189. I have a lifetime of notable experiences with Sierra bullets, but my rifle did not particularly like this one. The culprit, no doubt, was the rifle’s long throat. The Hornady 75-grain hollowpoint, with its ballistic coefficient of .257, performed somewhat better with several sub-one-inch groups. The Hornady 75-grain V-MAX, on the other hand, performed admirably. Its ballistic coefficient, due to its polymer tip, checks in at .290.

A sea of change took place when I got to 85-grain and heavier bullets. Extreme spreads and, most importantly, group sizes all shrank. Roberts’s work would have predicted this but should be expected anyway with any cartridge, as increased bullet weight tends to flatten time/pressure curves and improve shot-to-shot consistency. The bullets are heavier, usually longer and perhaps better suited to the barrel twist rate. The Nosler 85-grain Ballistic Tip came first and has a polymer tip, thin jacket walls, a solid base and a boat-tail. Its ballistic coeffieient is an impressive .329. Accuracy was uniformly excellent.

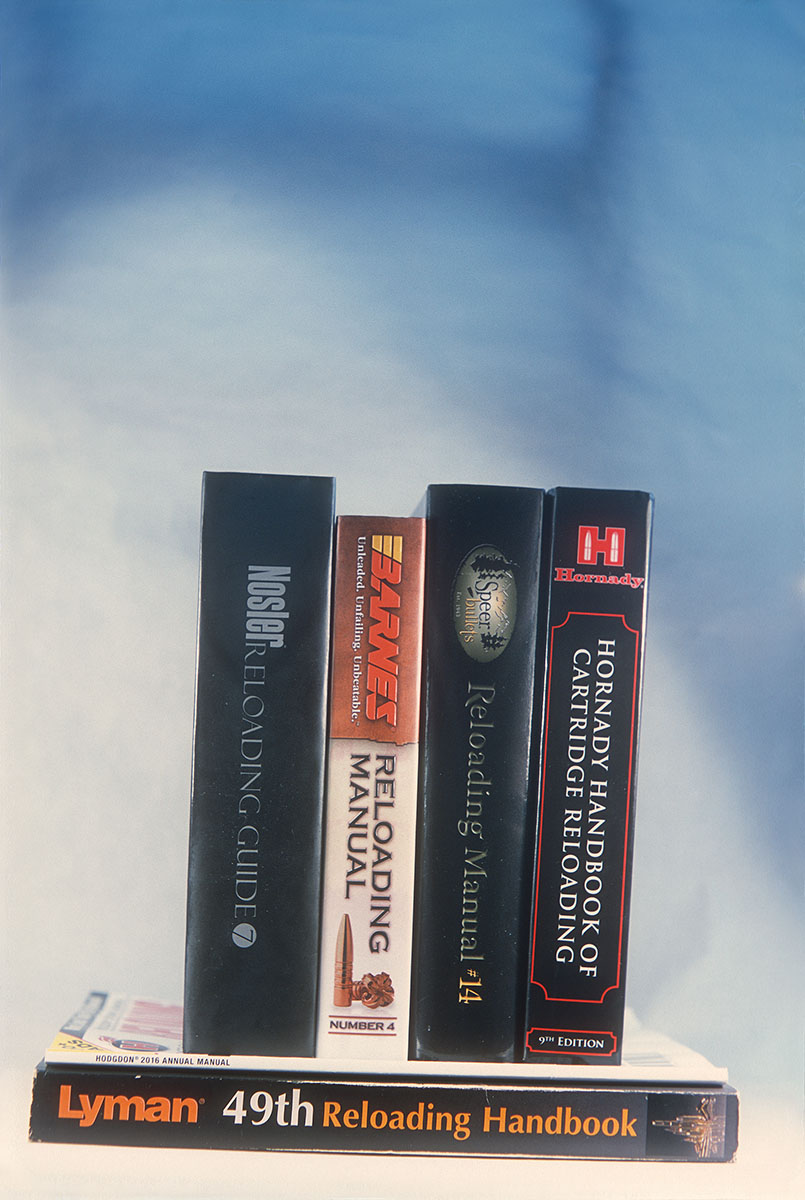

Powder choices become almost overwhelming; there are certainly 25 or more powders that could be considered appropriate for this range of bullet weights in this cartridge. Fifteen were selected for testing. While IMR-4350 is likely the best powder for bullets of 100 to 120 grains in the 257 Roberts, for bullets in the varmint range of 70 to 90 grains, things become more problematic. For extruded powders, I would want IMR-4895 on hand, followed closely by Reloder 15. For spherical (ball) powders, both H-380 and H-335 should certainly be tried. Although no load data specifically calls for it, I’d try both standard and magnum strength primers with these ball powders, especially as temperatures drop. There were other powders that performed well in the limited opportunities afforded them. These include Accurate 2495, a single-base, extruded powder and IMR’s new double-base extruded Enduron powders, IMR-4451 and IMR-4955. Both of these were limited to use with the Sierra 90-grain bullet. All these other powders, interestingly, were made at the same Ontario, Canada, facility as other Accurate and IMR extruded powders.

Regarding pressure, most hand-loaders understand that the 257 Roberts was initially loaded to a SAAMI maximum average pressure of 45,000 CUP. In recent years we have seen a “+P” version with a pressure limit of 50,000 CUP. This amounts to about 1.5 grains of powder. All the maximum loads in the accompanying table likely exceed the 45,000 CUP level, although none exceeds the “+P” level. Actually, in my rifle with its extended throat, it is very unlikely that any load, with the possible exception of those with Sierra 90-grain bullets, exceed even the standard pressure level. But, as always, and especially if your rifle has a standard throat, treat maximum loads as just that and begin by cutting powder charges by about 10 percent or, more specifically, about 4.0 grains.

The SAAMI specified overall cartridge length is predicated on a short-action receiver. Most, but not all, published load data also assumes a short action. As a result, most lengths in reloading manuals reflect a cartridge overall loaded length of 2.780 inches or less. Oddly, it seems to me, Nosler has elected to hold all lengths, regardless of bullet weight, to 2.750 inches. No attempt was made herein to match ideal cartridge length to my rifle, as there would be few, if any, rifles with the same chamber and throat dimensions. Instead, a standard length of 2.780 inches was used in most cases. In your own rifle, it would be wise to experiment. An included table lists potential overall cartridge lengths for each bullet used in the tests.