17 Ackley Improved

Loads for a Classic Wildcat

feature By: Layne Simpson | April, 18

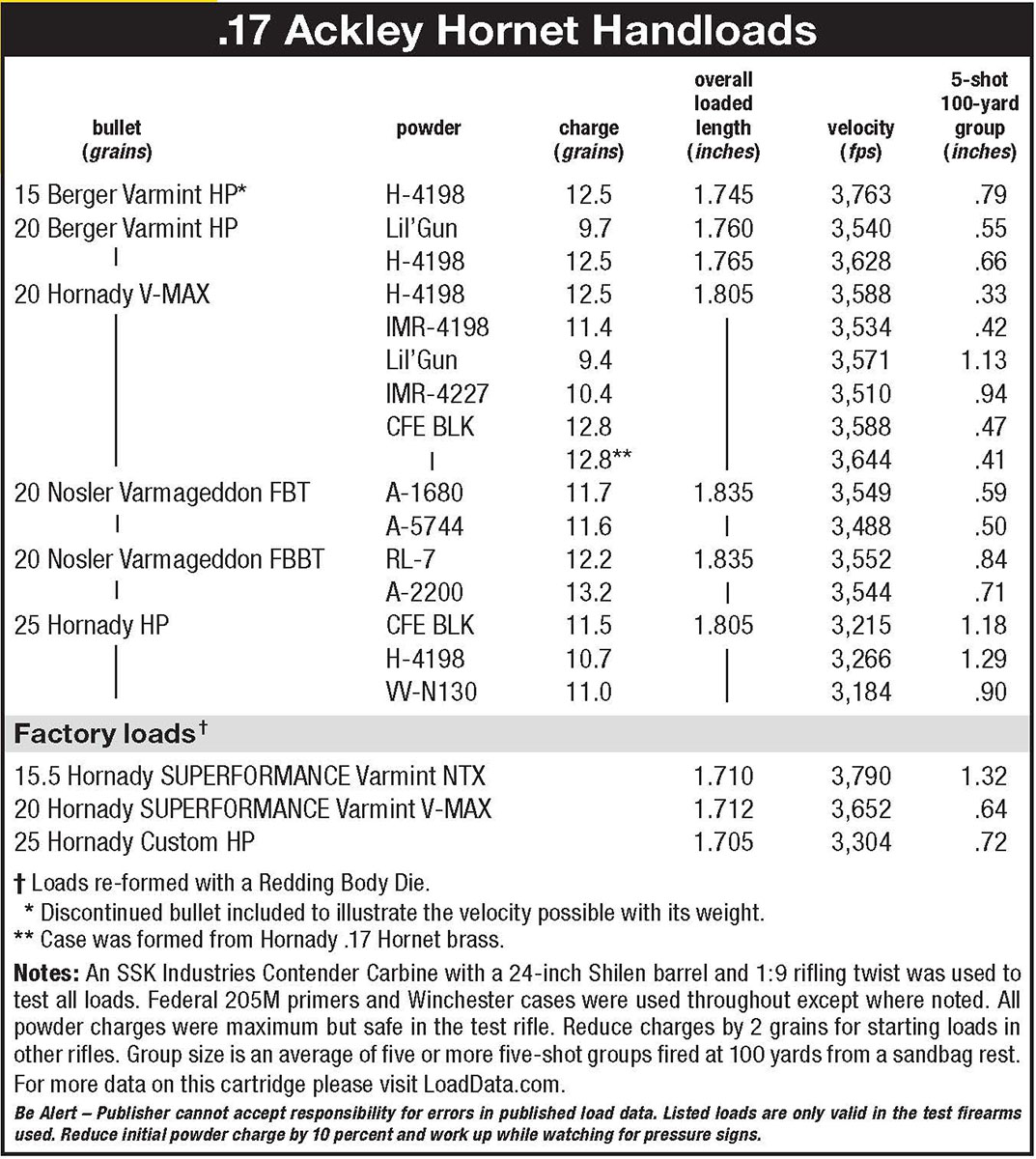

One wonders if bullet weight in the Ackley data might have been a typo. Hodgdon’s 2018 Annual Manual shows a maximum velocity of 3,242 fps for a 25-grain bullet at a chamber pressure of 45,000 psi. Hodgdon did reach and even exceed 3,500 fps, but with a 20-grain bullet. So how fast is the 17 Ackley Hornet and how does its velocity compare with its bigger cousins? Velocity will vary from rifle to rifle, but from the 24-inch barrel of the SSK Industries custom Contender I am presently shooting, maximum velocities for 20- and 25-grain bullets are in the neighborhood of 3,575 fps and 3,250 fps, respectively. Higher velocities are possible, but case life is shortened.

When loaded to maximum with a 20-grain bullet, the 17 Mach IV and 17 Remington Fireball will average about 300 fps faster while the 17 Remington outpaces those two by about the same amount. For bumping off prairie dogs and groundhogs as far away as a .17-caliber cartridge should be used, the bigger cartridges have a noticeable edge. But when surrounded by thousands of vicious, grass-munching flickertails, no cartridge is more fun to shoot than the 17 Hornet.

Since the 17 Ackley Hornet is a wildcat with no carved-in-stone standardization, shoulder angle as well as various case dimensions can vary slightly in rifles from various builders. A grinder’s drawing of the reamer used to chamber my rifle indicates 30 degrees, but I have also seen 35- and 40-degree versions. Through the years gunsmiths have produced basically the same improved cartridges of various calibers, and even though shoulder angle might have varied, all were called a “Ackley Improved” with visions of a famous name selling more rifles than, say, “Smith Improved.”

Forming 17 Ackley Hornet cases is easy. Die sets from RCBS and Redding come with an extended shellholder. Running a case through the form die necks it down to .20 caliber. The trim die squeezes the neck on down close to .17 caliber, and its hardened surface allows squaring up the mouth of the case with a fine-tooth file. Chamfering and deburring, followed by a trip through a full-length resizing die, readies the case for loading. Switching to a neck-sizing die after the initial firing prolongs case life.

When both are filled to the brim, the 17 Ackley Hornet case holds a grain more water than the 17 “Hornady” Hornet. While that would not be a lot in a 300 magnum, it represents about a 7 percent capacity increase in the tiny Hornet case. When both are loaded to the same pressure and fired in barrels of the same length, the Ackley should be about 100 fps faster than the Hornady with all bullet weights. Hodgdon came close to verifying that when both were loaded with the Hornady 20-grain V-MAX and fired in 24-inch pressure barrels. Maximum velocity for the Ackley version was 78 fps faster at 7,500 psi lower pressure.

Using Hornady 17 Hornet cases in lieu of 22 Hornet brass eliminates the necessity of buying form dies for the Ackley version. A requirement during its design stage was to make the Hornady cartridge short enough to work in the magazines of 22 Hornet rifles. Doing so required shortening the Hornet case so body taper was reduced in order to gain back some of the reduction in powder capacity. And while the 17 Ackley Hornet case has less body taper than the 22 Hornet case, it has a bit more taper than the 17 Hornady case. The difference prevents the Hornady case from fully entering the Ackley chamber, but a trip through a 17 Ackley Improved full-length resizer fixes that.

The case headspaces on its rim during fireforming and a reduced-charge load pushes the shoulder forward to the Ackley position. Ron Reiber of Hodgdon recommends the application of a light coat of Hornady One-Shot case lube to each case prior to fireforming. After cases are formed they are full-length resized to headspace on the shoulder rather than on the rim. The neck of a 17 Ackley case formed from Hornady brass will be shorter than on one formed from 22 Hornet brass, and for that reason case neck tension on a bullet will be less. This appears to have no affect on accuracy with any of the powders tried in my rifle, but some powders out there may require a stronger bullet pull for a uniform burn. This is easily accomplished by slightly reducing the diameter of the expander button of the resizing die, or by using a Redding Type-S, bushing-style resizer with a bushing .003 inch smaller than the neck diameter of a loaded round.

During my youth I shot a custom single-shot rifle in 17 Ackley Hornet built on a Winchester Model 1885 action belonging to one of my father’s hunting pals. He owned no powder scale and simply filled the case to the brim with IMR-4198, seated a bullet on top and went varmint shooting. A charge weighing 12.5 grains completely fills a case formed from Winchester 22 Hornet brass. IMR-4198 and H-4198 have long been traditional choices, but denser powders usually flow through powder measures with less charge-to-charge weight variation. Speaking of that, anyone who shoots large quantities of ammunition and does not use a progressive press simply must have Redding’s

Switching to the Remington 6½ primer sometimes improves accuracy, but its cup is softer than the Remington 7½, Federal 205M and CCI 400, and it may not handle some of the pressures to which the 17 Ackley Hornet is loaded. Ron Reiber uses it in the 17 “Hornady” Hornet, but he stays a bit below maximum. Primer preference shows up in rifles chambered for the 17 Hornets more often than those chambered for other cartridges. One of two custom rifles belonging to a friend is more accurate with the Remington 6½ while the other prefers the Winchester Small Rifle primer (WSR). A Cooper rifle I shot sometime back performed best with the Federal 205M. My SSK rifle also prefers that primer.

Extremely light .17-caliber bullets are dependent on velocity for effectiveness on varmints, and the faster the better. In my experience, that rules out the use of 25-grain hollowpoints in the 17 Ackley Hornet. Hornady’s V-MAX of that weight is better because, due to a higher ballistic coefficient, it does a better job of bucking wind and is more likely to expand once velocity drops off. But the small 17 Ackley Hornet case is unable to push it to the velocities needed, and that makes the Hornady and Nosler 20-grain plastic-tip bullets the best choices. Nosler and Berger offer 20-grain hollowpoints, but their respective .119 and .120 ballistic coefficients (BCs) lose out to the .183 BC of Nosler’s tipped bullet and the .185 BC of the Hornady V-MAX. Even so, both are quite accurate. Every shooter occasionally gets lucky and punches an extremely small group; the smallest to date from my rifle is .223 inch with the Berger bullet.

While faster cartridges shoot flatter and are more wind resistant, Ackley’s Hornet is no slouch in those departments. Zero the Hornady 20-grain V-MAX – exiting the muzzle at 3,600 fps – 2 inches high at 100 yards and it is 2 inches high at 200 yards and 4 inches low at 300, which is about as far away as it will consistently kill ground squirrels and other varmints of that size. Hits at greater distances are possible on a calm day, but some critters will make it underground to die a lingering death, and we want no part of that.

The little cartridge is better at slicing through wind than some shooters believe. Drift in a 10-mph cross breeze is 6 inches at 200 yards, and 14 inches at 300. In comparison, a 50-grain V-MAX exiting the muzzle of a 223 Remington at 3,400 fps drifts 5 inches at 200 yards, and 11 inches at 300. For the Hornady 35-grain V-MAX moving from my 22 K-Hornet at 3,200 fps, drift is 13 and 35 inches at those distances.

The first rifle in 17 Hornet I used to thin the flickertail population was built during the mid-1980s by the original Kimber of Oregon. On the Model 82 action, there were actually two versions. The 17 Kimber is on a shortened 22 Hornet case while the 17 Kimber R2 is on the full-length case. Except for slightly less body taper and the shoulder moved forward a tiny bit, the latter cartridge is the same as the Ackley version. It also produces the same velocity. My rifle never consistently shot inside .5 inch at 100 yards, but it came close with several loads. I became quite fond of it through the years and then suddenly, a Kimber collector loved it even more.

There was a time when .17-caliber cartridges were a pain in the neck to shoot, but the coming of smooth bores, good bullets and effective bore cleaners such as Sweet’s 7.62 and Shooter’s Choice changed that. Not long ago I shot a couple of rifles in 17 Hornet during the tail-end of a media event. I was the last person to shoot the rifles, and more than 200 rounds of Hornady factory ammunition had already been fired in each of them without either barrel being cleaned. I squeezed off five, five-shot groups at 100 yards without letting their barrels cool down between groups. Average group size was .535 inch with one, and .717 inch with the other.

Shooting 17 Hornet Ammunition in a 17 Ackley Hornet Rifle

As previously mentioned, the 17 Hornady case has a bit less taper than the 17 Ackley Hornet case, and for that reason it won’t fully seat in the chamber of a 17 Ackley Hornet rifle. Run the case through a 17 Ackley Hornet full-length resizing die and it will chamber. After trying handloads with cases formed in that manner in my 17 Ackley Hornet rifle, I just had to see how factory ammunition would work.

Using an inertia puller, bullets were removed from factory ammunition and before dumping the powder into a small container, each charge was weighed. The average was 22.3 grains. Running the cases through a 17 Ackley Hornet full-length resizing die with its decapping pin removed reduced body diameter a bit while leaving the primer in place. I expected chamber pressure to be lower in the improved chamber, but to be on the conservative side, the factory charge was reduced to 21.3 grains, and then carefully increased in .2-grain increments until the original charge weight was reached. The pulled bullets were then seated to the original overall cartridge length of 1.712 inches.

While the experiment was informative, the amount of time and effort involved made shooting 17 Hornady ammunition in a 17 Ackley Hornet rifle less than practical. Then suddenly, that big light bulb in my head began glowing brightly. There is a way to lightly resize Hornady ammunition without taking it apart and putting it back together, and it’s called a body die.

Benchrest shooters spend a lot of time preparing cases for competition. Among other things, case necks are turned to a close fit with the undersized chamber neck of their rifle. And since many of them shoot damn-the-torpedoes loads, those precious cases grow to an excessively tight fit in the chamber after very few firings. Their solution is to run cases through a die that bumps back the shoulder and reduces body diameter just enough to allow the case to enter the chamber with only a bit of resistance to bolt closure. The die does not resize the neck of the case. Redding has been making body dies for benchrest shooters for many years. They were originally available only for a few cartridges, and since not many were sold, they were not cataloged. The company now offers body dies for all but a few bottleneck cases.

I had used body dies on 22 PPC, 6mm PPC and 6mm BR cases, but the thought of using one to resize a loaded round had not dawned on me until trying 17 Hornady Hornet cases in my 17 Ackley Hornet rifle. Diameter at the body/shoulder juncture of the Hornady case needs to be reduced by only .004 inch, so resizing is slight. Neck diameter of the die cavity is a close fit with the neck of a loaded round, and it does a good job of keeping a cartridge in alignment during resizing. I ran 100 rounds each of the three Hornady factory loads through the Redding die, and two of them proved to be quite accurate; pressure appeared to be mild.

I saw no reason why the procedure would be unsafe, but prior to including it in this report I ran it by Robin Sharpless of Redding. In his words, “I don’t see a problem. The body of the die is open at the top and does not crimp or hold the bullet. The chance of an accidental discharge is no different than when seating a bullet. You found a good alternative use for our 17 Ackley Hornet body die.” It is important to remember that the procedure described in determining that Hornady factory ammunition could be safely fired in my 17 Ackley Hornet rifle should be followed prior to trying it in other rifles.