Remington's 5mm Rimfire Magnum

Shooting a Classic

feature By: Layne Simpson | April, 22

The bottleneck case of the 5mm Magnum was a bit shorter than the 22 WMR case but a body diameter about 10 percent larger made room for more powder. Rim diameter was close to 11 percent larger. Due to a higher ballistic coefficient, the Remington bullet shot a bit flatter, although it was not enough to matter at the effective ranges of both cartridges. More important in the field, 5mm Magnum residual velocity at that

Fifty-round boxes of ammunition under the Remington and Peters Cartridge Company labels would be offered. Clouds began to darken when it was revealed that a box of ammunition would likely cost around $4.50. A box of 22 WMR was about $1.50 less, and at the time that cartridge had yet to really catch on and was struggling for survival.

The Model 591 in 5mm Magnum fed from a four-round detachable magazine while the tubular magazine of the Model 592 held 10 rounds. Both rifles were displayed at the Remington seminar, but oddly enough, neither was made available for firing. Sometime later, the reason was revealed. The breeching system of the action was designed around the 22 Long Rifle with its mild chamber pressure and support of the 5mm Magnum case was inadequate to contain the considerably higher pressure to which it was loaded. Several rounds might fire without incident and then, suddenly, a case would rupture at the extractor slot of the chamber. Shortly after the conclusion of the seminar, all who attended were informed “the project has been cancelled until further notice.”

It took Remington engineers just over a year to come up with a solution. First, the face of the bolt was made perfectly flat and when the bolt was locked, it rested firmly against the equally flat breech end of the barrel. That, along with counterboring the mouth of the chamber, totally enclosed the rim of a chambered round. But the counterbore wall had to be slotted to allow the rim to be engaged by the extractor. That part of the cat was skinned with a very unusual two-part, two-stage extraction system that still allowed the rim of a case to be totally supported during firing. Here is how it works.

A close-fitting primary extractor resting in a slot in the side of the chamber is rigidly supported by snug contact between its backside and the wall of the receiver. This feature alone was enough to prevent the rim of the case from rupturing, but a secondary extractor riding on a sloped ramp in the side of the receiver was needed to make it all work. As the bolt is opened and begins its trip to the rear, it draws the primary extractor to the rear about .250 inch and that begins extraction of the fired case from the chamber. Meanwhile, the secondary extractor begins its trip down the ramp and engages the rim of the case just before the primary extractor releases it. At this time, the primary extractor disengages and returns to its seat in the wall of the chamber. As the bolt continues its trip to the rear, the secondary extractor pulls the case against an ejector with enough force to fling it out through the ejection port.

With the case rupturing issue corrected, the 5mm Remington Magnum was reintroduced in late 1969 at a seminar held at the famous Y.O. Ranch in Texas. Attendees were given the opportunity to use one of the rifles to bump off a turkey gobbler. At the time, rifles could legally be used for harvesting Thanksgiving dinner in my home state, and I often used a Winchester Model 54 in 22 Hornet and a reduced-velocity handload pushing a 40-grain bullet to 2,100 fps or so. The 5mm Remington Magnum proved to be equally deadly. Rather than shipping the rifles back to the factory, Remington left them in Texas, where they became the official turkey medicine at the Y.O. Ranch. For many years thereafter, the rifle rack in pickups driven by the guides there held a Model 591 or a Model 592. Centerfire rifles brought by most hunters who were after deer and other game were a bit much for use on the big birds and through the decades, those Remingtons accounted for hundreds of them.

In 2008, Aguila came to the rescue of those who had hung onto their rifles by offering two 5mm Magnum loadings under the Centurion Ordnance label. Maximum average chamber pressure was 33,000 psi, same as for Remington ammunition, but velocity was increased to 2,300 fps by reducing the bullet weight to 30 grains. Giving the new bullets a higher ballistic coefficient flattened trajectory with no sacrifice in residual energy. The jacketed hollowpoint bullet expanded explosively out to 200 yards or so, making it an excellent choice for bumping off chipmunks, flickertails and other small critters. Expansion of the jacketed softnose bullet was more controlled, making it better for use on larger varmints.

That production run of ammunition eventually sold out and it would be 2019 before Aguila began shipping a new batch from its factory in Cuernavaca, Mexico. Not long thereafter, the ammunition was also being loaded at the company’s new plant located in Conroe, Texas. The 30-grain JHP load was back, but the 30-grain JSN load had been replaced by what was described as a semi-jacketed hollowpoint of the same weight. Like the old bullet, it had a nose cavity, but unlike the old bullet, a bit of lead core was exposed at the nose. The JHP load was still the one to use on flickertails and other small varmints and the SJHP load offered deeper penetration on foxes and coyotes called in close. The ammunition was loaded to the same pressure as the 2008 loadings.

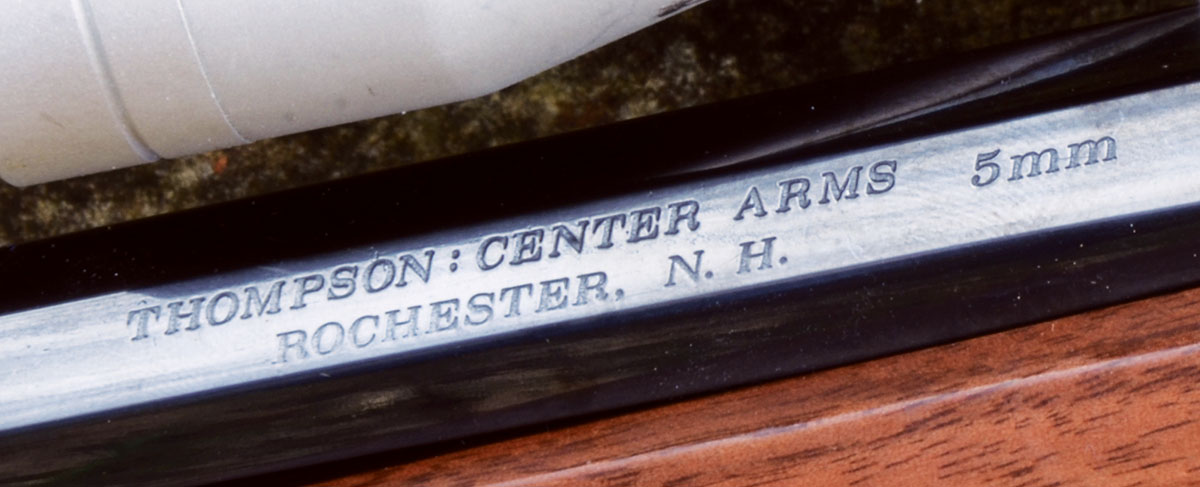

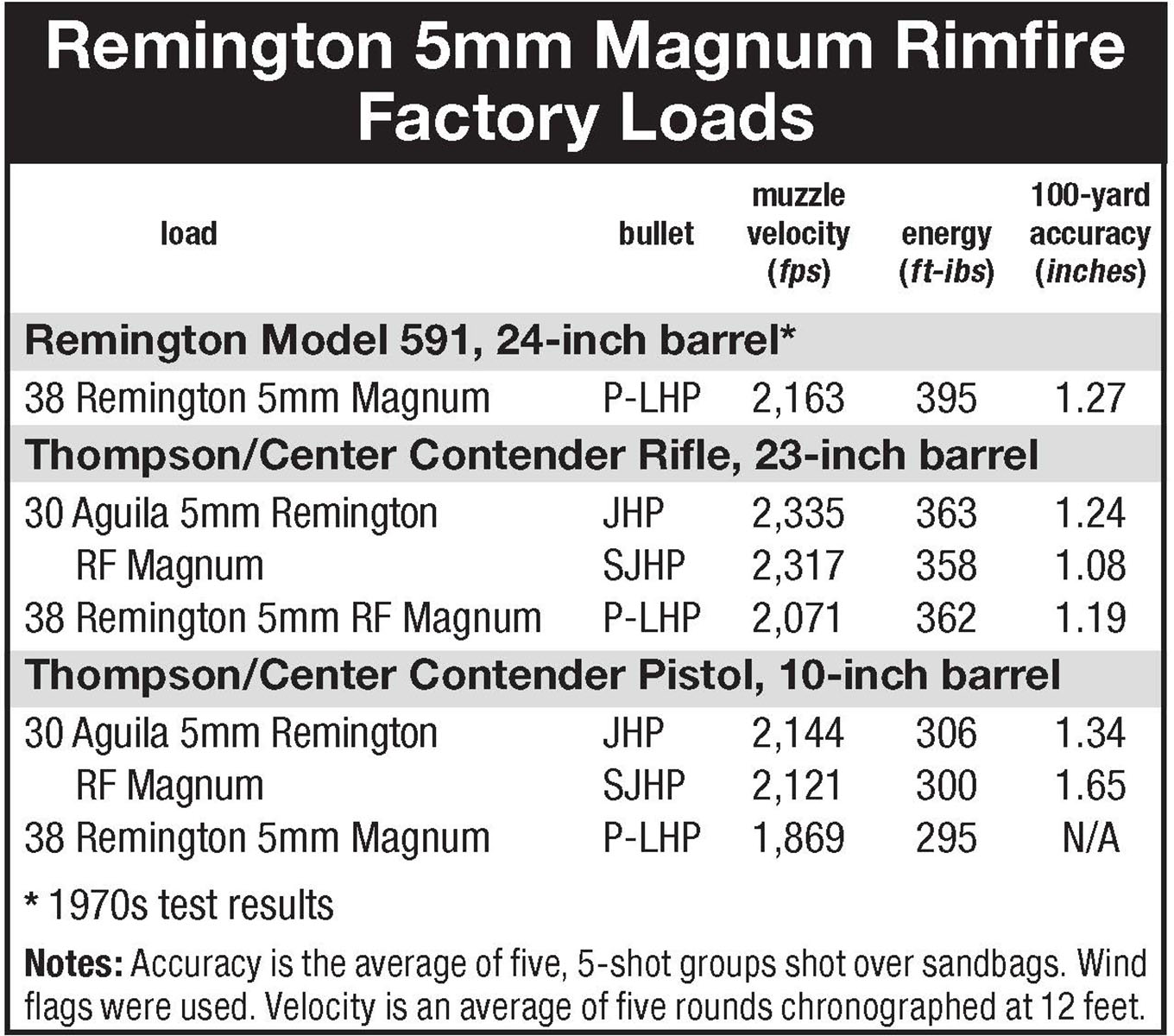

With my Remington Model 591 long gone, I shot the Aguila loads in two Thompson/Center single-shots. One was a Contender rifle with a fairly heavy 23-inch barrel with a muzzle diameter of .810 inch. It originally had a T/C 3-9x scope, but eventually switching to a Bushnell Elite 4200 in 6-24x increased my head-shot percentage on distant chipmunks by leaps and bounds. The other test gun was a Contender pistol with a light, 10-inch octagon barrel measuring .650 inch across the flats. It had a 2.5-8x Nikon Monarch handgun scope. I shot the rifle with a Lyman Bag Jack up front and a bunny-style sandbag at the rear. The pistol was nestled in a MTM Pistol Rest with the butt of its grip resting on a flat sandbag.

I was surprised to see the two Aguila loads exceed 2,100 fps from the 10-inch barrel of the pistol. That’s faster than many 22 WMR loads from a rifle. Velocity from the 23-inch barrel exceeded Aguila claims. The Remington load was a bit slower, understandable since its bullet is eight grains heavier and the ammunition had to be at least 36 years old. Also, the test barrel used by Remington was an inch longer than the barrel of my rifle.

Moving to the 17 HMR, it was 140 foot-pounds for a 20-grain bullet. Respective 100-yard velocities listed for the three cartridges were 1,669, 1,495 and 1,776 fps. Like I said, don’t be a bit bashful about uncasing your Model 591 or Model 592 in a crowd of varmint shooters armed with rifles chambered for the 22 WMR and 17 HMR.